Continuous production method of 2-methyl tetrahydrofuran

A technology of methyl tetrahydrofuran and production methods, applied in the direction of organic chemistry, can solve the problems affecting the industrialization of process technology, the cost of catalyst toxicity, and the small amount of raw material treatment, so as to reduce the use and danger of toxic catalysts and high-cost precious metals. The effect of small, large amount of raw material processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

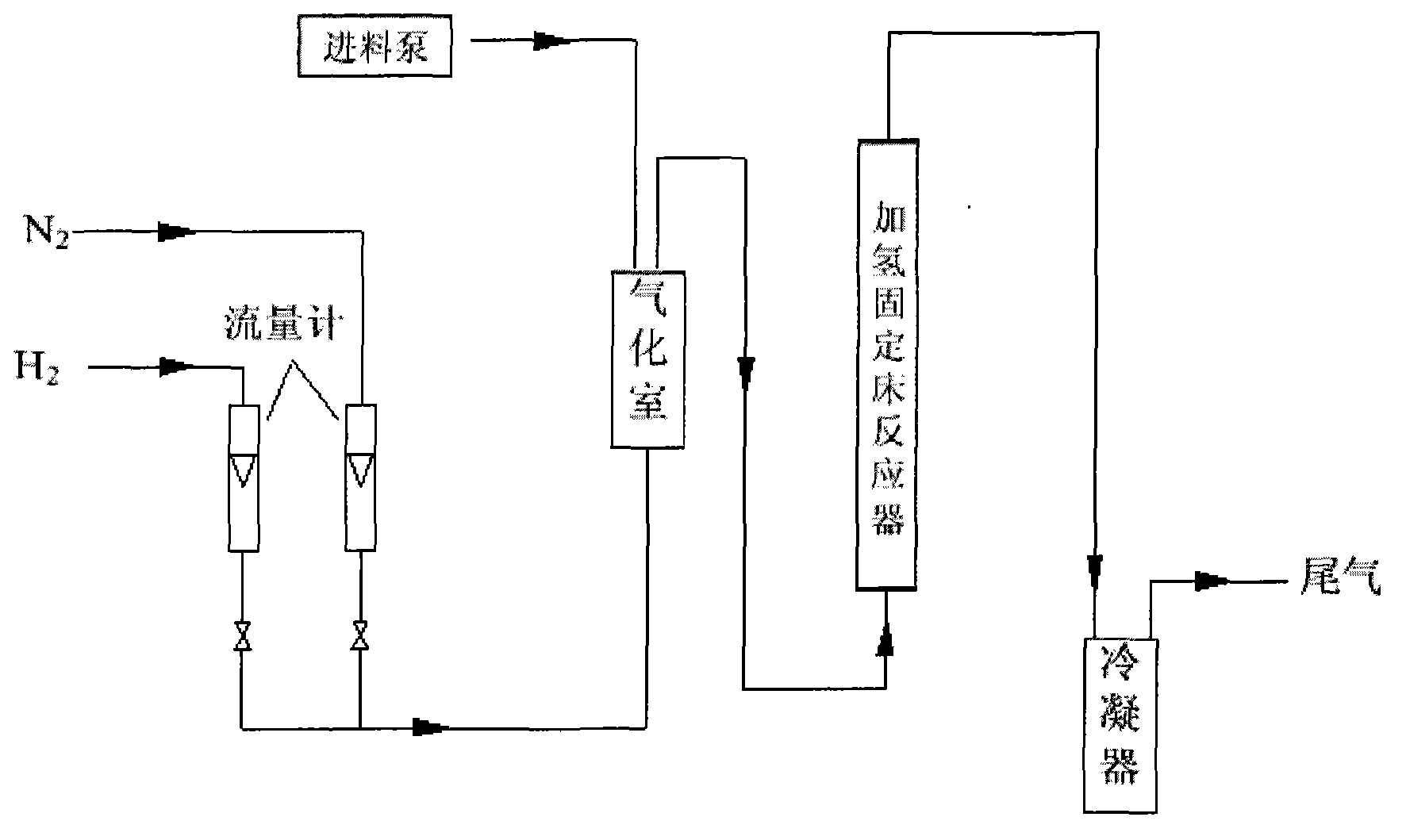

[0034] Reaction equipment: continuous hydrogenation system composed of gasification chamber, hydrogenation fixed bed reactor (DN25 white steel pipe, length 50cm), and condenser.

[0035] reaction process:

[0036] (1) The hydrogenation fixed-bed reactor is packed by wet method. First fill about 150 g (wet weight 240 g) of Raney Ni catalyst (product number RTH-2123E, from Datong General Chemical Co., Ltd.), and the height of the catalyst bed after filling is about 15 cm. Temperature measuring points are respectively set on the upper part and the lower part of the catalyst bed of the hydrogenation fixed bed reactor.

[0037] (2) Flow nitrogen through the hydrogenation fixed-bed reactor from top to bottom, and at the same time adjust the temperature of the hydrogenation fixed-bed reactor to 130 ° C, and use the nitrogen / hydrogen mixture to activate and dry the Raney Ni catalyst by conventional technical means Treat and remove air from the reaction system. In the mixed gas, the...

Embodiment 2~4

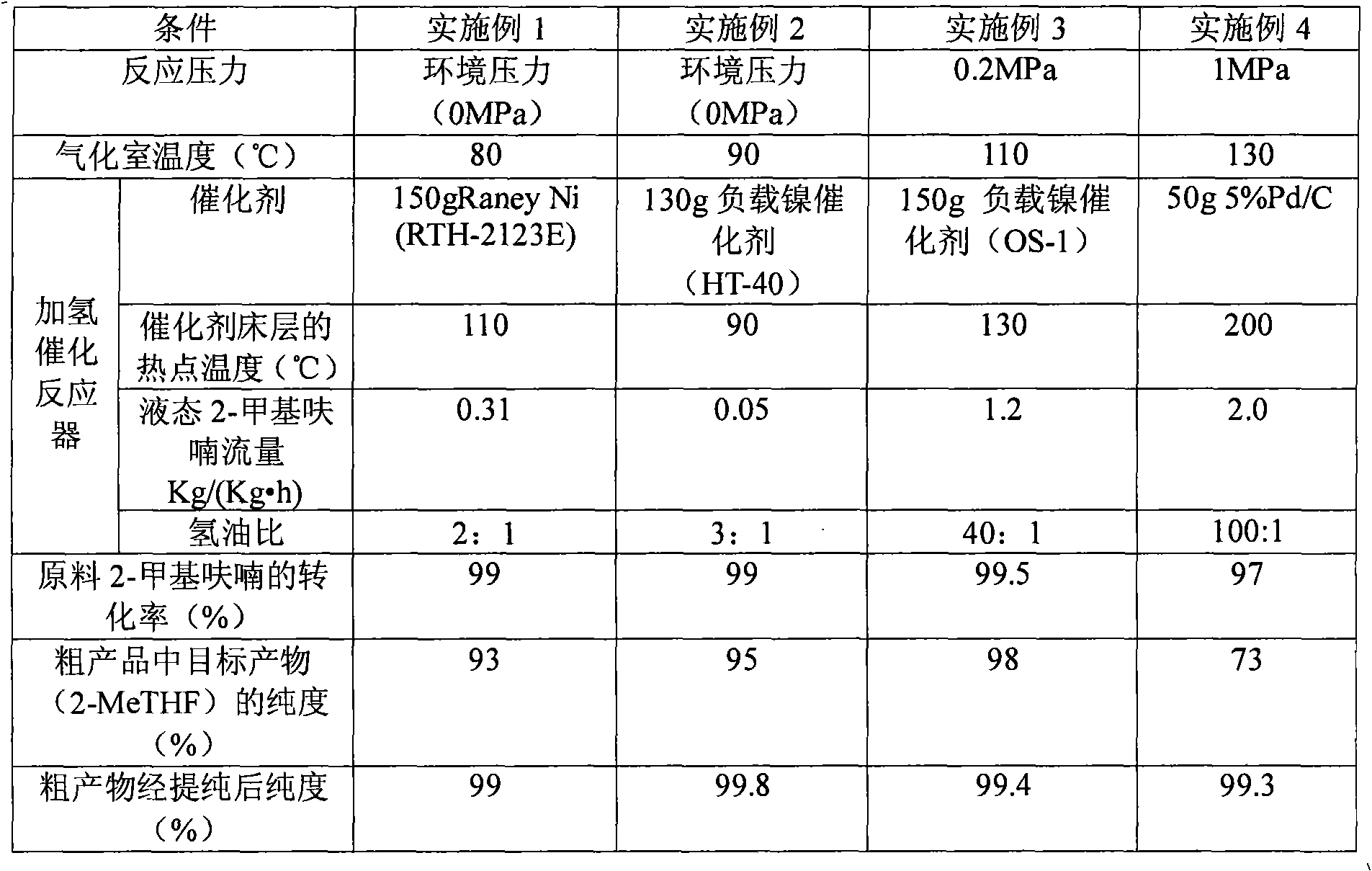

[0039] The operating steps of Example 1 are basically the same, except that the reaction pressure, catalyst type, flow rate of 2-methylfuran, hot spot temperature of the catalyst bed in the hydrogenation fixed-bed reactor, hydrogen and 2-methylfuran flow rate The molar ratio etc., can refer to Table 1 specifically.

[0040] Table 1

[0041]

[0042] Note: The hydrogen-to-oil ratio is the molar ratio of hydrogen flow to vaporized 2-methylfuran flow. Both the supported nickel catalyst HT-40 and the supported nickel catalyst OS-1 were from Liaoning Haitai Technology Development Co., Ltd. The 5% Pd / C (supported palladium on carbon) catalyst was from Johnson Matthey Company.

[0043] As can be seen from the data of Examples 1 to 4, the present invention has realized the method for continuously producing 2-MeTHF by gas phase reaction under low pressure or ambient pressure (0~1.0MPa) by 2-methylfuran, has changed the traditional The production of 2-MeTHF requires high-pressure,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com