Preparation method of 2-methyl furan

A technology of methyl furan and furfural, which is applied in the field of 2-methyl furan preparation, can solve the problems of low heat utilization rate, loss utilization rate, high energy consumption of 2-methyl furan products, and achieve reasonable heat recycling , The effect of low one-time investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation method of 2-methylfuran provided by the invention comprises: under selective hydrogenation reaction conditions, in the presence of a hydrogenation catalyst, the gaseous phase furfural is contacted with hydrogen in a hydrogenation reactor to carry out a hydrogenation reaction, and the reaction The product is condensed and the organic phase and the water phase are separated, and the obtained organic phase is sent to a rectification tower for rectification to obtain 2-methylfuran, wherein at least part of the heat released during the hydrogenation reaction is taken out by heat exchange As a heat source for the distillation column.

[0018] According to the present invention, the place that generates heat in the production process of 2-methylfuran mainly comes from the large amount of heat that releases when gaseous phase furfural and hydrogen contact reaction, and in the refining process of follow-up 2-methylfuran crude product, need In the rectification to...

Embodiment 1

[0041] This example is used to illustrate the preparation of 2-methylfuran provided by the present invention.

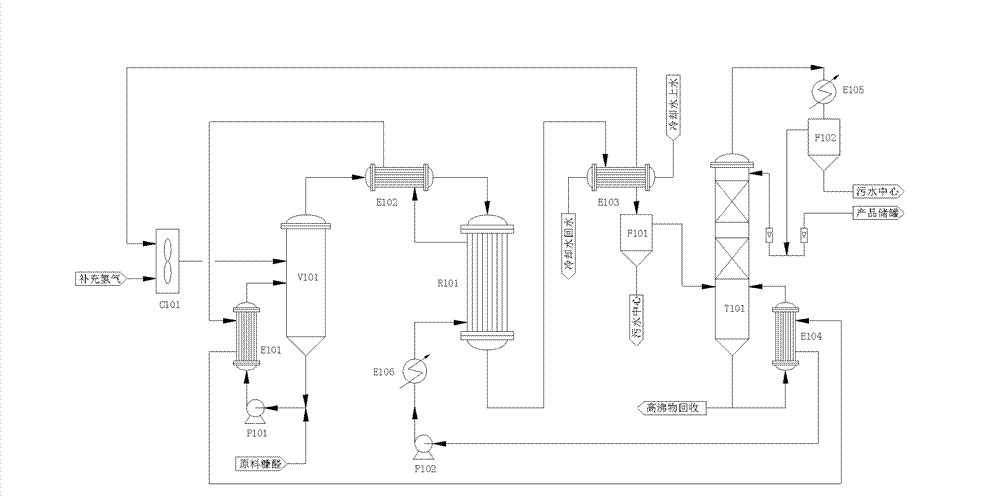

[0042] in such as figure 1 The preparation of 2-methylfuran is carried out in the continuous reaction device shown. The furfural raw material in the liquid phase is heated to 100°C by the furfural heater E101 and then enters the furfural evaporator V101 to be vaporized into a gas. The furfural in the gas phase and the circulating hydrogen are sent to the aldehyde The hydrogen superheater E102 is heated to 140°C, and then the heated gas phase furfural and hydrogen are sent to the hydrogenation reactor R101 (shell-and-tube reactor) for hydrogenation reaction (the hydrogenation reaction temperature is 180°C, and the pressure is 0.2 MPa, the molar ratio of gaseous furfural to hydrogen is 1:16; the hydrogen space velocity is 700h -1 , the catalyst loading capacity is 5 tons), the high-temperature gas after the reaction is sent to the condenser E103 to be condensed to 5°C...

Embodiment 2

[0050] This example is used to illustrate the preparation of 2-methylfuran provided by the present invention.

[0051] in such as figure 1 Carry out the preparation of 2-methylfuran in the continuous reaction device shown, and carry out the preparation of 2-methylfuran according to the processing method of embodiment 1, difference is, with the 2-methylfuran device technology of 1000 tons / year To illustrate, the hydrogenation reaction temperature is 170°C, the pressure is 0.2MPa, the molar ratio of gaseous furfural to hydrogen is 1:20; the hydrogen space velocity is 800h -1 , the catalyst loading capacity is 2 tons; the rectifying condition: the rectifying tower T101 bottom temperature is 110 ℃, and the tower pressure is normal pressure (0.1MPa). Among them, heat transfer oil is used to provide heat source for the system, the flow rate of all heat transfer oil is 60t / h, and the pressure of the heat transfer oil delivery system is 0.2-0.4MPa.

[0052] The heat transfer oil inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com