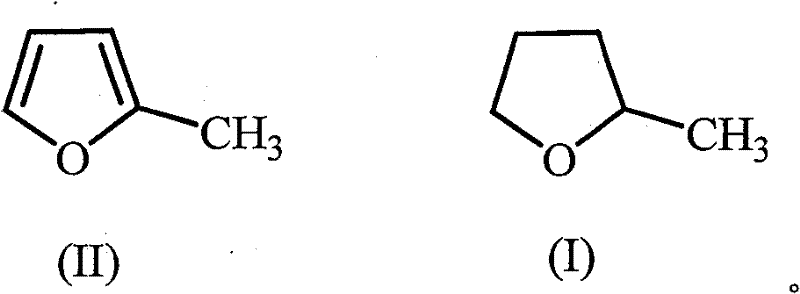

Green synthesis of 2-methylte-trahydrofuran

A technology of methyltetrahydrofuran and a synthesis method, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, organic chemistry, etc., can solve the problems of high-component catalysts under reaction pressure, and achieve good popularization and application. Prospect, easy recovery, and the effect of reaction pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of ruthenium and a non-noble metal zinc simultaneously loaded on the catalyst of activated carbon carrier: 3%Ru.5%Zn / C. The operation steps are as follows: Weigh 0.62g of RuCl 3 and 1.05g ZnCl 2 , add pure water to make a 300mL aqueous solution, pour it into a 500mL 3-necked flask, then add 10.0g of activated carbon carrier, seal it and let it stand in a constant temperature water bath at 25°C for 12 hours, then raise the temperature to 50°C and stir for 2 hours. Then use NaOH to adjust the pH value of the solution to 9, then use analytically pure formaldehyde to reduce and filter, and wash the filter cake with deionized water until there is no chloride ion in the filtrate. After suction filtration, put the filter cake in a vacuum oven and dry it at 100°C for 3 hours That is the composite catalyst.

[0032] Preparation of 2-MeTHF: In a pressure reactor, add 100g of MeF and 1g (1% of the mass of MeF) of the composite catalyst prepared above, and carry out a ...

Embodiment 2-4

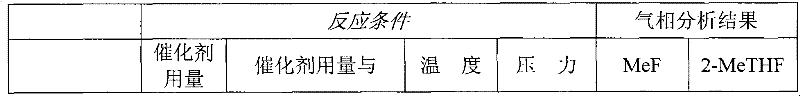

[0034] Change the mass ratio of the catalyst 3%Ru.5%Zn / C to 2-methylfuran in Example 1, as well as the reaction temperature and reaction pressure. Other operations are as in Example 1. The experimental conditions and experimental results are shown in Table 1.

[0035] Table 13%Ru.5%Zn / C composite catalyst reaction results

[0036]

[0037]

Embodiment 5-9

[0039] Preparation of 12% Ru.10% Zn / C composite catalyst: RuCl 3 and ZnCl 2 Change the consumption of 2.48g and 2.10g into, and all the other operation steps are with embodiment 1. Use this composite catalyst to carry out hydrogenation reaction, change the mass ratio of catalyst and 2-methylfuran, reaction temperature and reaction pressure, other operations are as in Example 1, and the experimental conditions and experimental results are shown in Table 2.

[0040] Table 212%Ru.10%Zn / C Composite Catalyst Reaction Results

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com