Method for preparing 2-methyltetrahydrofuran catalyst through gas phase hydrogenation of 2-methylfuran

A technology of methyl tetrahydrofuran catalyst and methyl furan, which is applied in the direction of heterogeneous catalyst chemical elements, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve difficult industrialization and liquid phase reaction Continuous, containing precious metal production costs and other issues, to achieve good activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

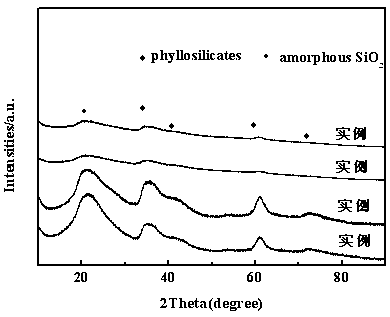

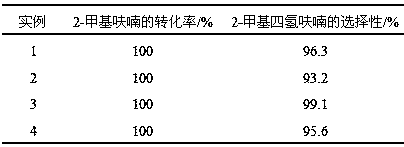

[0020] Weigh 3.9 g of hydrated nickel nitrate and dissolve it in 50.0 g of water, add 15.2 g of ammonia water and stir, after complete dissolution, add 34.0 g of silica sol and 0.3 g of calcium nitrate and seal and stir for 4 h, then evaporate ammonia at 70 °C under the assistance of ultrasonic waves When the pH is 6-7, the ammonia distillation is stopped, the obtained precipitate is washed, dried at 120 °C for 12 h, and calcined at 700 °C for 4 h to obtain the catalyst.

Embodiment 2

[0022] Weigh 19.5 g of nickel nitrate hydrate and dissolve it in 150.0 g of water, add 50.0 g of ammonia water and stir, add 32.0 g of silica sol and stir for 4 h after complete dissolution, then evaporate ammonia gas at 80°C under the assistance of ultrasonic waves, and wait until the pH is Stop ammonia distillation at 6-7 o'clock, wash the obtained precipitate, dry at 120°C for 12 h, and roast at 600°C for 4 h to prepare the catalyst.

Embodiment 3

[0024] Weigh 16.7 g of nickel nitrate hydrate and dissolve it in 120.0 g of water, add 40.2 g of ammonia water and stir, and after it is completely dissolved, add 11.6 g of silica sol, seal and stir for 4 h, then evaporate ammonia gas at 90°C under the assistance of ultrasonic waves, and wait until the pH is 6 Stop ammonia distillation at -7, wash the obtained precipitate, dry at 120 °C for 12 h, and roast at 650 °C for 4 h to prepare the catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com