Method for realizing efficient co-extraction of tungsten and vanadium from waste SCR (Selective Catalytic Reduction) denitrification catalyst

A denitration catalyst and high-efficiency technology, applied in chemical instruments and methods, inorganic chemistry, vanadium compounds, etc., can solve the problems of low recovery rate of vanadium and tungsten, poor reactivity, high energy consumption, etc., achieve low vanadium and tungsten content, and slag discharge The effect of reducing the amount of water and reducing the amount of water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

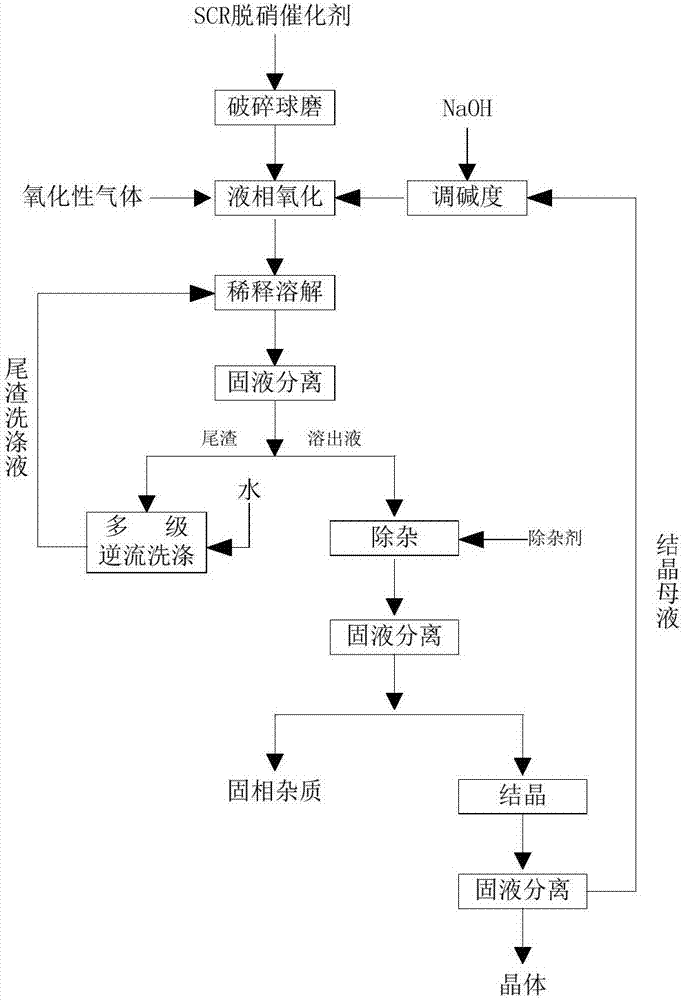

Method used

Image

Examples

Embodiment 1

[0041] (1) Pretreatment: crush and ball-mill the waste SCR denitration catalyst to 250 mesh;

[0042] (2) Ingredients: mix 70g of waste SCR denitration catalyst with 50% NaOH solution, the mass ratio of NaOH to waste SCR denitration catalyst is 10:1;

[0043] (3) Stripping reaction: the slurry in step (2) is carried out in a 1L high-pressure stirred reactor, and oxygen and oxygen are introduced to carry out a gas-liquid-solid three-phase stripping reaction, and the partial pressure of oxygen is 5Mpa. The reaction temperature is 200°C. The time is 5h, and the stirring speed is 180 rpm;

[0044] (4) Dilution and heat preservation: dilute and heat-preserve the dissolution slurry obtained in step (3), until the alkali concentration is 400g / L, and the heat-preservation range is 120°C;

[0045] (5) Solid-liquid separation: the diluted slurry obtained in step (4) is subjected to solid-liquid separation to obtain tailings and NaOH, Na 3 VO 4 、Na 2 WO 4 and the eluate of water-sol...

Embodiment 2

[0050] (1) Pretreatment: crush and ball-mill the waste SCR denitration catalyst to 20 mesh;

[0051] (2) Ingredients: Mix 150 g of waste SCR denitration catalyst with NaOH solution with a mass concentration of 20%, and the mass ratio of NaOH to waste SCR denitration catalyst is 3:1;

[0052] (3) Stripping reaction: the slurry in step (2) is carried out in a 1L high-pressure stirred reactor, and oxygen is introduced to carry out a gas-liquid-solid three-phase stripping reaction, and the oxygen partial pressure is 3Mpa. The reaction temperature is 150°C, and the reaction time For 3h, the stirring speed is 120 rpm;

[0053] (4) Dilution and insulation: Dilute and insulate the stripping slurry obtained in step (3) until the alkali concentration is 150g / L, and the insulation range is 80°C;

[0054] (5) Solid-liquid separation: the diluted slurry obtained in step (4) is subjected to solid-liquid separation to obtain tailings and NaOH, Na 3 VO 4 、Na 2 WO 4 and the eluate of wate...

Embodiment 3

[0059] (1) Pretreatment: 100g of waste SCR denitrification catalyst is crushed and ball milled to 80 mesh;

[0060] (2) Ingredients: mix the waste SCR denitrification catalyst with a NaOH solution with a mass concentration of 28%, and the mass ratio of NaOH to the waste SCR denitration catalyst is 5:1;

[0061] (3) Stripping reaction: the slurry described in step (2) is carried out in a 1L high-pressure stirred reactor, and oxygen is introduced to carry out gas-liquid-solid three-phase stripping reaction, the oxygen partial pressure is 4Mpa, the reaction temperature is 120°C, and the reaction time For 3h, the stirring speed is 100 rev / min;

[0062] (4) Dilution and heat preservation: the stripping slurry obtained in step (3) is diluted and heat-preserved until the alkali concentration is 235g / L, and the heat-preservation range is 100°C;

[0063] (5) Solid-liquid separation: the diluted slurry obtained in step (4) is subjected to solid-liquid separation to obtain tailings and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com