Method for laterite-nickel ore resourceful treatment and comprehensive recycling

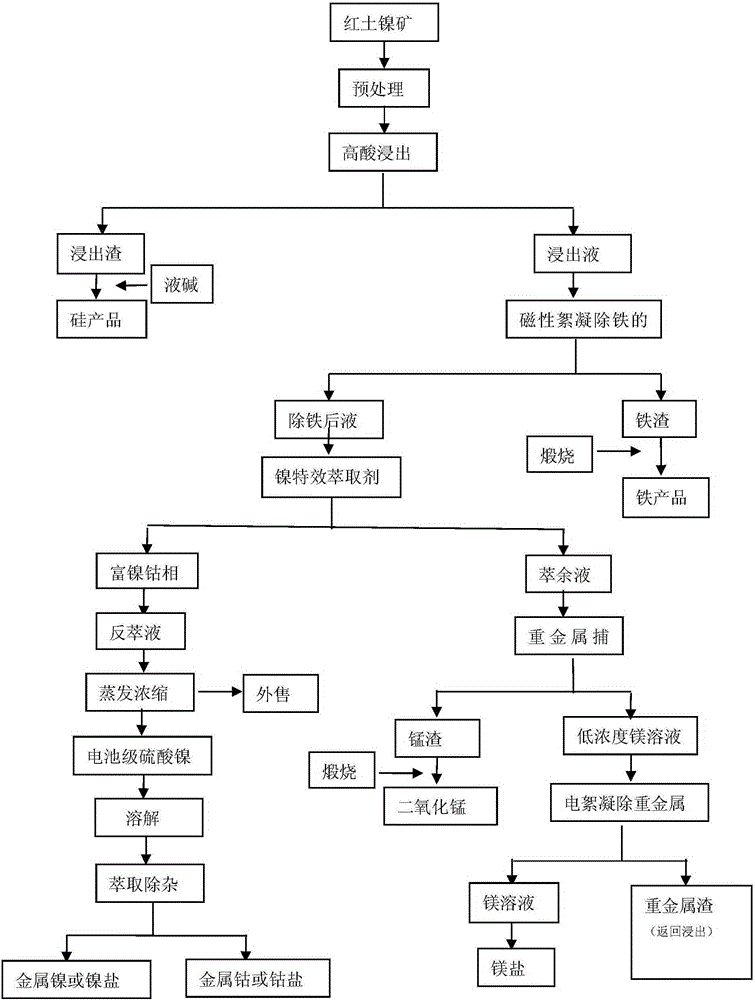

A technology of laterite nickel ore and resource utilization, which is applied in the field of hydrometallurgy and smelting, can solve the problems of loss of nickel and cobalt along the process, high cost, and many returned materials, and achieves the effect of high nickel recovery rate and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for resource processing and comprehensive recycling of laterite nickel ore, comprising the following specific steps:

[0038] a) Pretreatment: Pretreatment includes adding water to the laterite nickel ore for slurrying and sieving, wherein the weight ratio of laterite nickel ore: water is 1:4-6, and then stirring for 0.5 hours to gradually pass through the mesh The sieve is 8mm and 1mm, and the oversize is crushed and ground, and mixed with the undersize, and the mixed pulp is passed through a cyclone separator to obtain at least 90% of the laterite nickel ore with a particle size of no more than 0.147mm. Enter the super thickener to obtain the underflow pulp with a mass concentration of 26-32%. The pulp larger than 0.147mm is returned to the grinding process. The supernatant is returned to the slurry washing cycle;

[0039] b) High acid leaching: Take 1500g of underflow pulp with a concentration of 30.64%, add 400g of concentrated sulfuric acid for leaching,...

Embodiment 2

[0050] A method for resource processing and comprehensive recycling of laterite nickel ore, comprising the following specific steps:

[0051] a) pretreatment: same as embodiment 1;

[0052] b) High-acid leaching: Take 30kg of underflow pulp with a concentration of 30.64%, add 8.6kg of concentrated sulfuric acid for leaching, the reaction pressure is normal pressure, the reaction temperature is 85-90°C, and the reaction time is 3 hours. slag; the leached slag was washed and dried to obtain 4.75 kg of dry slag, and the combined leaching solution and washing water were 28.64 L of solution. See Table 1 below for specific components;

[0053] Table 1 The specific components of the combined leachate and washing water

[0054] the element

Fe

Ni

co

Mg

mn

Contentg / L

21.65

4.63

0.10

34.86

0.77

18.67

[0055] Table 2 Concrete components of leaching slag

[0056] the element

Fe

Ni

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com