Co-extraction method for pillar-less coal and gas of advanced entry-retaining construction extraction engineering

A technology without coal pillars and gas, which is applied in the direction of gas discharge, ground mining, mining equipment, etc., can solve the problems of high cost of drainage engineering, many processes, low air permeability, etc., and achieve the goal of reducing the section size of the roadway and saving costs time, the effect of prolonging the extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

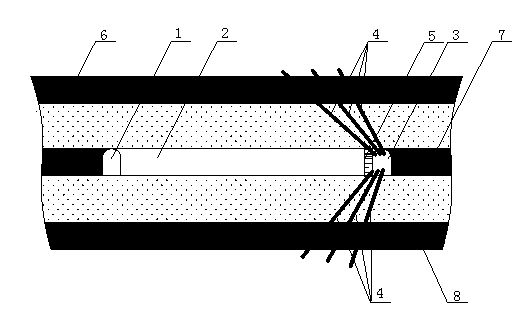

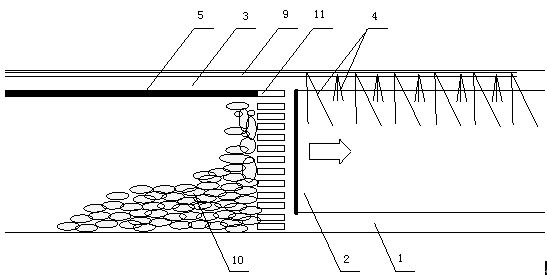

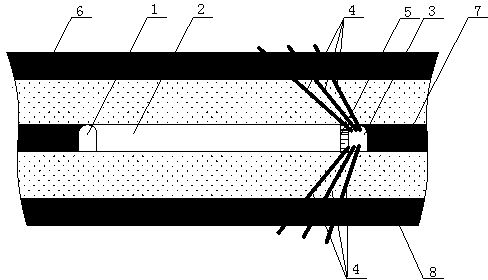

[0019] like figure 1 As shown, in the coal pillar-free coal and gas co-mining method of the advanced entry retention construction drainage project of the present invention, the gas drainage pipeline and the gas drainage project are arranged in the gob-side entry retention 3, and the gas drainage pipeline and the gas drainage Mining projects are interconnected. Coal seam gas enters the mine gas drainage system through gas drainage engineering and gas drainage pipelines. The distance between the drill holes arranged in the advanced working face and the front of the working face can be 0-500 m, the diameter of the construction drilling holes in the advanced working face can be 10-350 mm, and the number of pre-construction drilling holes can be 2-10, The angle of drilling for pre-construction can be 0°~180°, and the layout of gob-side entry retention can be high-water and high-efficiency filling, filling with cast-in-place concrete partition wall, large-scale self-moving gob-side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com