Novel co-extraction system for extraction of lithium from high magnesium-lithium ratio bittern and co-extraction method using the same

A high-magnesium-lithium ratio brine, a new type of technology, applied in the field of chemical industry, can solve the problems of low lithium recovery rate of stripping rate, high price, corrosion of equipment, etc., to reduce production cost and equipment investment, extraction rate and stripping rate The effect of increasing and reducing the cost of lithium extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A new co-extraction system for extracting lithium from brine with high magnesium-lithium ratio, the extractant is tributyl phosphate, the diluent is sulfonated kerosene, and the co-extractant is potassium hexafluorophosphate.

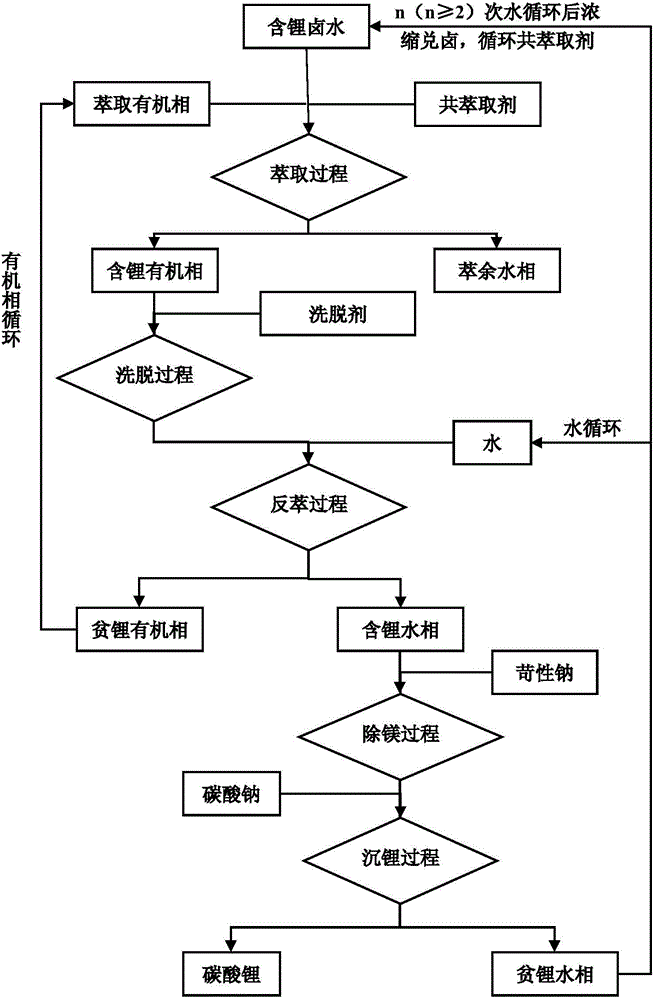

[0037] A novel co-extraction method for extracting lithium from brine with high magnesium-lithium ratio, the specific steps are as follows:

[0038] ⑴ Prepare the extraction organic phase: Mix 40mL tributyl phosphate and 10mL sulfonated kerosene to make the extraction organic phase; take 50mL of a salt lake brine, in which Li + =0.24g / L, Na + =1.50g / L, K +=2.90g / L, Mg 2+ =95.80g / L, the mass ratio of magnesium to lithium is 404.65;

[0039] ⑵Extraction: Add the extracted organic phase and potassium hexafluorophosphate to the salt lake brine to fully shake the extraction, the PF of potassium hexafluorophosphate 6 - with Li + The molar ratio is 2, the volume ratio of the extracted organic phase to the aqueous phase is 1:1, the single extractio...

Embodiment 2

[0047] A new co-extraction system for extracting lithium from brine with high magnesium-lithium ratio, the extractant is tributyl phosphate, the diluent is sulfonated kerosene, and the co-extractant is sodium tetrafluoroborate.

[0048] A novel co-extraction method for extracting lithium from brine with high magnesium-lithium ratio, the specific steps are as follows:

[0049] ⑴ Prepare the extraction organic phase: Mix 40mL tributyl phosphate and 10mL sulfonated kerosene to make the extraction organic phase; take 50mL of a salt lake brine, in which Li + =0.24g / L, Na + =1.65g / L, K + =1.03g / L, Mg 2+ =96.81g / L, the mass ratio of magnesium to lithium is 394.80;

[0050] ⑵Extraction: Add the extracted organic phase and sodium tetrafluoroborate to the salt lake brine to fully shake the extraction, the BF of sodium tetrafluoroborate 4 - with Li + The molar ratio is 2, the volume ratio of the extracted organic phase to the aqueous phase is 1:1, the single extraction time is 10mi...

Embodiment 3

[0058] A new co-extraction system for extracting lithium from brine with high magnesium-lithium ratio, the extractant is tributyl phosphate, the diluent is methyl isobutyl ketone, and the co-extractant is potassium hexafluorophosphate.

[0059] A novel co-extraction method for extracting lithium from brine with high magnesium-lithium ratio, the specific steps are as follows:

[0060] ⑴ Preparation of extraction organic phase: Mix 40mL tributyl phosphate and 10mL methyl isobutyl ketone to make extraction organic phase; take 50mL of a salt lake brine, Li + =2.30g / L, Na + =3.69g / L, K + =10.56g / L, Mg 2+ =76.87g / L, the mass ratio of magnesium to lithium is 33.42;

[0061] ⑵Extraction: Add the extracted organic phase and potassium hexafluorophosphate to the salt lake brine to fully shake the extraction, the PF of potassium hexafluorophosphate 6 - with Li + The molar ratio is 2, the volume ratio of the extracted organic phase to the aqueous phase is 1:1, the single extraction t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com