Cleaner production process for synchronously extracting vanadium and aluminum from aluminothermic vanadium iron slag

A technology for simultaneous extraction of ferrovanadium slag, applied in the field of metallurgy, can solve the problems of low recovery rate of vanadium, failure of resource utilization of aluminum, etc., and achieve the effects of significant economic and environmental benefits, reduction of carbon emission ratio, and high-efficiency extraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

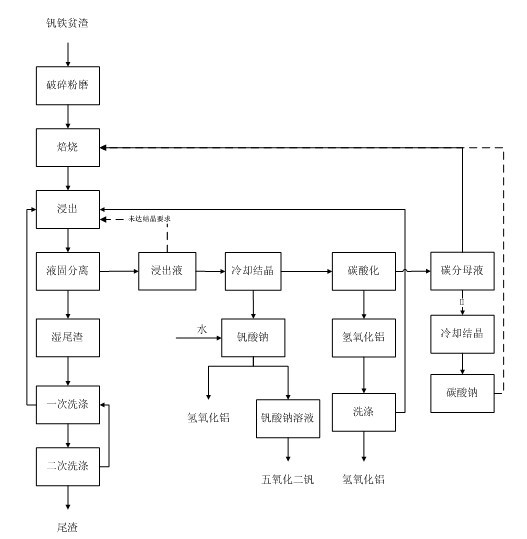

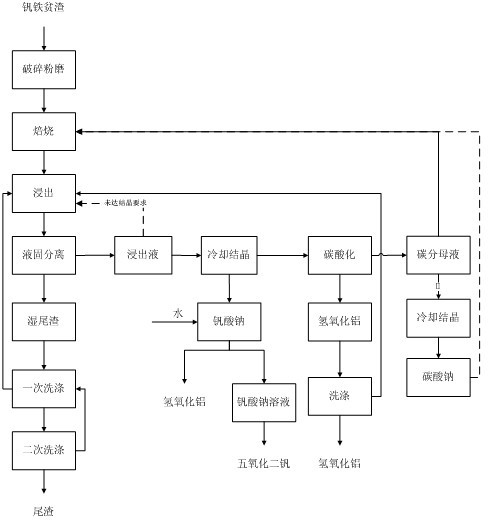

Image

Examples

Embodiment 1

[0012] Embodiment 1, a clean production process for synchronously extracting vanadium and aluminum from the aluminothermic ferrovanadium slag, comprising the following steps:

[0013] (1) Crushing and ball milling the iron-vanadium slag to make the particle size below -120 mesh;

[0014] (2) Ingredients: Na 2 CO 3 Mix with ferrovanadium slag in a ratio of 1:1 by weight, and stir evenly;

[0015] (3) Roasting: Roast the mixed material at a temperature of 900°C for 4 hours;

[0016] (4) Leaching: Put the clinker into the leaching solution, leaching at the leaching temperature of 80°C, the leaching time is 30min, the liquid-solid ratio is 1.5:1, and the alkalinity of the leaching solution is 260.5g / L. The leaching rate of vanadium pentoxide is 89.1%, the leaching rate of aluminum is 69.3%, the concentration of aluminum in the leach solution is 102.3g / L, and the concentration of vanadium is 9.26g / L;

[0017] (5) Washing: the filtered filter cake is washed with water at 80°C; ...

Embodiment 2

[0021] Embodiment 2, a clean production process for synchronously extracting vanadium and aluminum from the aluminothermic ferrovanadium slag, comprises the following steps:

[0022] (1) Crushing and ball milling the iron-vanadium slag to make the particle size below -120 mesh;

[0023] (2) Ingredients: add Na 2 CO 3 Mix with the return liquid (carbon mother liquid) vanadium iron slag of the previous reaction in a ratio of 1:1.0 by weight;

[0024] (3) Roasting: Roast the mixed material at a temperature of 900°C for 5 hours;

[0025] (4) Leaching: Put the clinker into the leaching solution (the tailings washing solution and the aluminum hydroxide washing solution from the last reaction), leaching at the leaching temperature of 80°C, the leaching time is 30min, and the liquid-solid ratio is 2:1. The alkalinity of the leach solution is 281.5g / L. The vanadium leaching rate is 87.6%, and the aluminum leaching rate is 72.5%. The leachate contains 113.6g / L aluminum and 11.65g / L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com