Recycling method for copper-indium-gallium-selenium materials

A technology of copper indium gallium selenide and recovery method, which is applied to chemical instruments and methods, gallium/indium/thallium compounds, element selenium/tellurium, etc., can solve the problems of volatile hydrochloric acid, high production cost, and reduced gallium recovery rate, etc. Achieve the effect of reducing acid gas pollution, solving the problem of co-extraction, and achieving good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

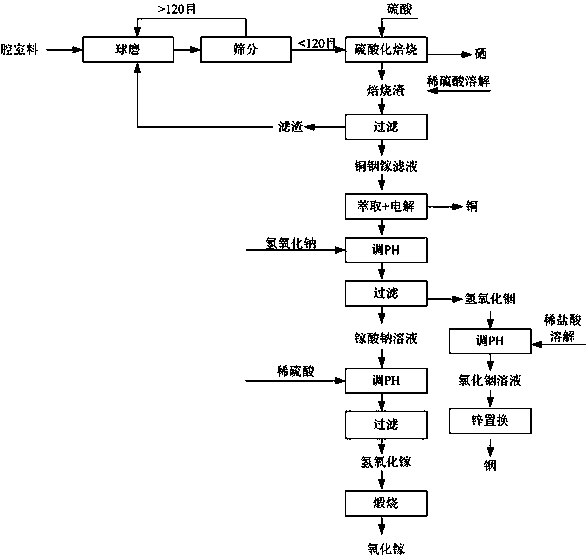

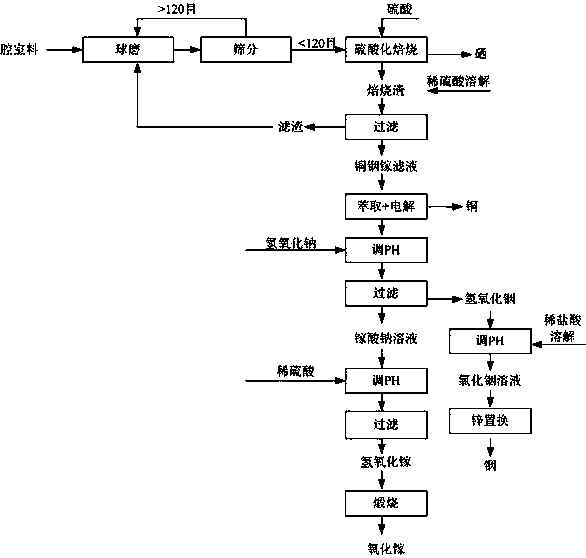

[0044] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0045] In step A, 400g of copper indium gallium selenide material is placed in a ball mill, ball milled to a powder below 120 mesh, and dried at 100° C. for 4 hours.

[0046] Step B: Mix the powder obtained in step A with 98% concentrated sulfuric acid and mix well. The liquid-solid ratio is 1:1. After roasting to 750°C, start blowing in air, absorb it with a secondary suction filter bottle, and roast for 6 hours.

[0047] Step C, detecting the selenium content in the calcined slag, if it exceeds a predetermined value, carry out secondary re-burning. Dissolve the final remaining calcined slag directly in 10% dilute sulfuric acid, and stir at room temperature for 30 minutes.

[0048] Step D, after dissolving and filtering, add 8mol / L sodium hydroxide solution to adjust the pH value to 1.8, then extract copper, use AD-100N as the extractant, dilute to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com