Co-extraction method of boron and lithium in brine

An extraction and brine technology, which is applied in the field of co-extraction and recycling of boron and lithium, can solve the problems of difficulty in effective phase separation between three liquid phases, cumbersome procedures, etc. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

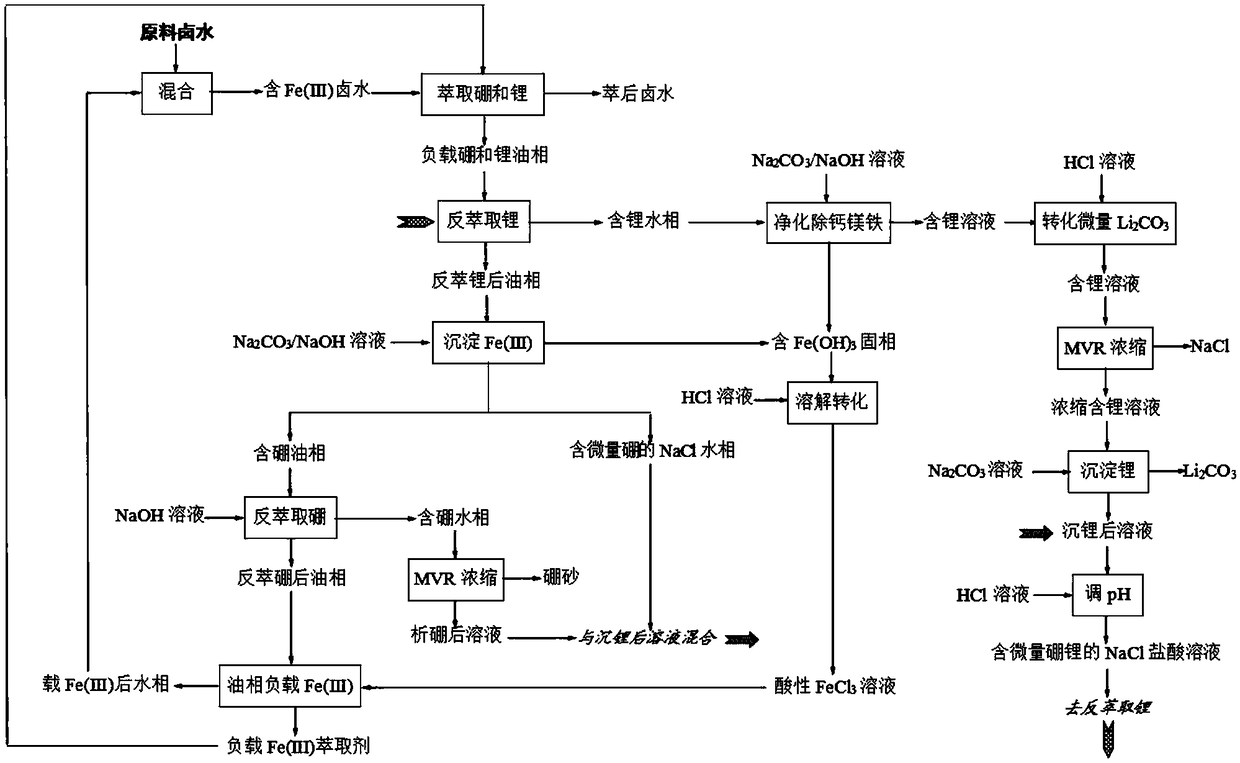

[0037] The following combined with the attachment and the specific embodiments further explained the present invention.

[0038] by figure 1 The craftsmanship shows boron -containing and lithium brine for boron and lithium to extract, and the brine team becomes Li + , NA + K + , CA 2+ , Mg 2+ CL - B 2 O 3 The content is 1.05, 63.52, 53.87, 4.38, 23.42, 226.35g / L.

[0039] Adjust the above brine pH 2.5, and then add FeCL 3 · 6H 2 O dissolved, gained brine containing boron, lithium, Fe (III), FE added 3+ LI in brine + The Moore is N (Fe / Li) ≈0.5.

[0040] Add FeCL 3 · 6H 2 O dissolution, obtain the co -oily phase of the load Fe (III), the added Fe 3+ LI in brine + Moorebi is n (Fe / Li) ≈ 1.5. Compared with O / A is 1: 1, the oil after the load FE (III) is relatively acidified and added after the FE (III) brine for five -level reverse streaming. Oil phase and post -extracting brine. Under this condition, the extraction rates of lithium and boron are 95.82 % and 99.68 %, respectively.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com