Supercritical CO extraction of Angelica dehurical oil resin

An angelica oleoresin and supercritical technology, applied in liquid solution solvent extraction, producing fat, essential oil/fragrance, etc., can solve the loss of volatile components and water-soluble components, adverse effects on sensory quality of products, and influence on the flavor of extracts, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

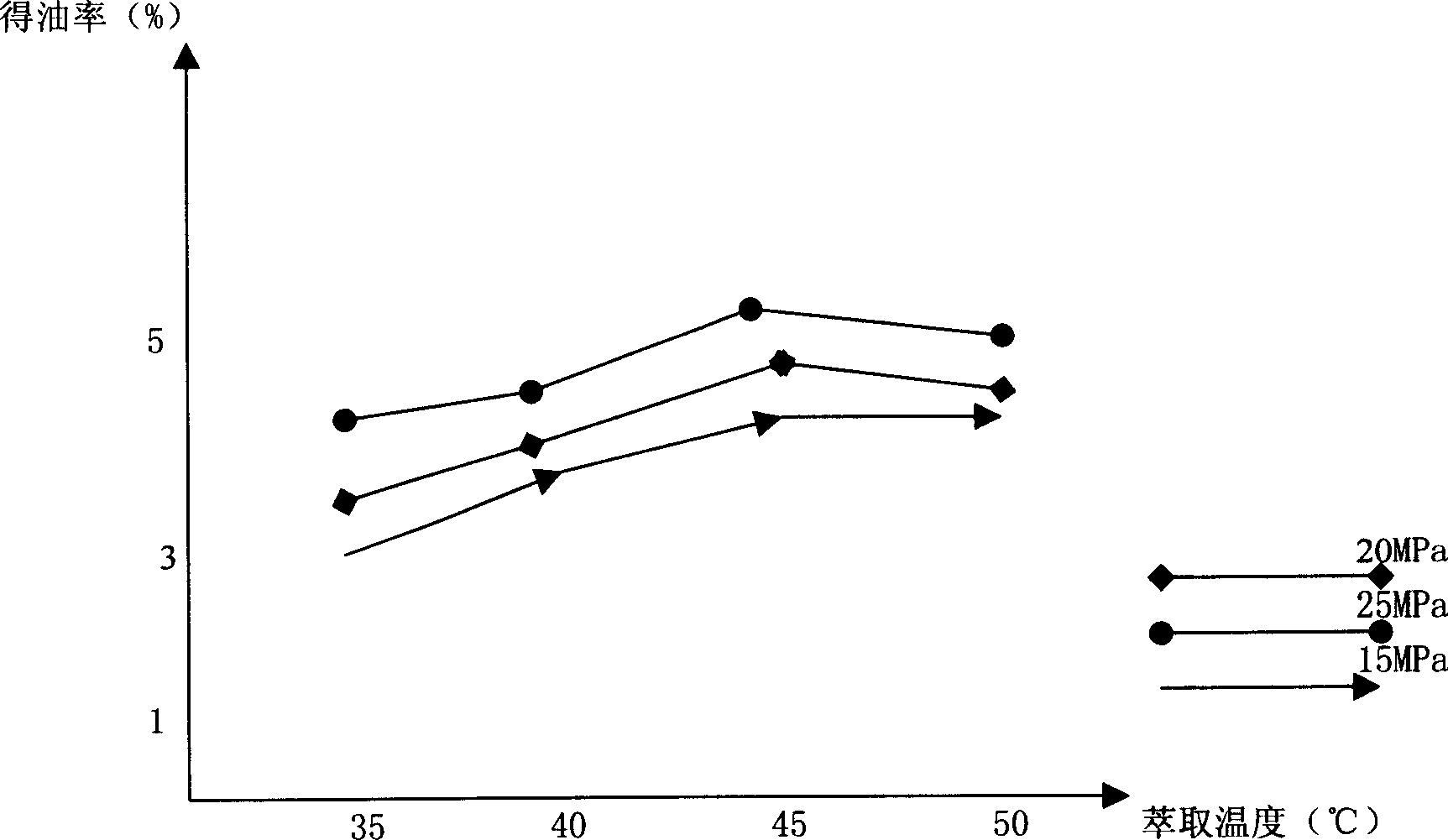

[0021] Example 2 Determination of extraction temperature:

[0022] See attached image 3 , The temperature rises, the molecular thermal movement speed increases, CO 2 The dissolving power increases; but at the same time the temperature rise also makes the supercritical CO 2 As the density decreases, its dissolving ability decreases correspondingly, resulting in a decrease in extraction efficiency. The extraction rate of oil mainly depends on which state prevails at this temperature. From image 3 It can be seen that when the temperature is lowered (35°C), the extraction oil yield is lower; as the temperature increases, the extraction oil yield increases, reaching the highest at 45°C; the temperature continues to rise, the extraction oil decreases instead. Therefore, the optimal extraction temperature is selected as: 45°C.

example 3

[0023] Example 3 Best CO 2 Determination of pump frequency:

[0024] See attached Figure 4 , CO 2 Pump frequency mainly controls CO 2 flow. CO 2 The increase of the pump frequency will speed up the flow rate of the supercritical fluid through the material, thereby increasing the density of the supercritical fluid, thereby increasing the solubility of the solute, shortening the time for the extraction to reach equilibrium, and improving the extraction rate of oil. by Figure 4 It can be seen that with CO 2 With the increase of pump frequency, the extraction rate of oil increased in different degrees, but when CO 2 When the pump frequency reaches 28 Hz, the extraction result has basically not changed. Description CO 2 The influence of pump frequency on the extraction result is basically close to equilibrium.

example 4

[0025] Example 4 Determination of extraction time:

[0026] See attached Figure 5 , CO 2 When the pump frequency is constant, with the extension of time, the extraction rate of oil is continuously increasing, but with the extension of time, the curve gradually becomes flat. by Figure 5 It can be seen that the change trend of the curve in the figure can explain that the extraction time in the early stage of extraction has a significant impact on the extraction results, and this effect is relatively reduced in the later stage. As an important parameter in industrial production, in actual production, considering the relationship between equipment energy consumption and extraction oil yield, the optimal extraction time is selected as 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com