Deep coal bed gas and heat co-extraction method

A coalbed methane and deep-seated technology, applied in mining fluids, mining equipment, earthwork drilling and mining, etc., can solve problems such as difficulty in determining the connectivity of mining and irrigation wells, low recharge efficiency, and groundwater pollution, so as to improve resource extraction rates and avoid waste, the effect of increasing air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

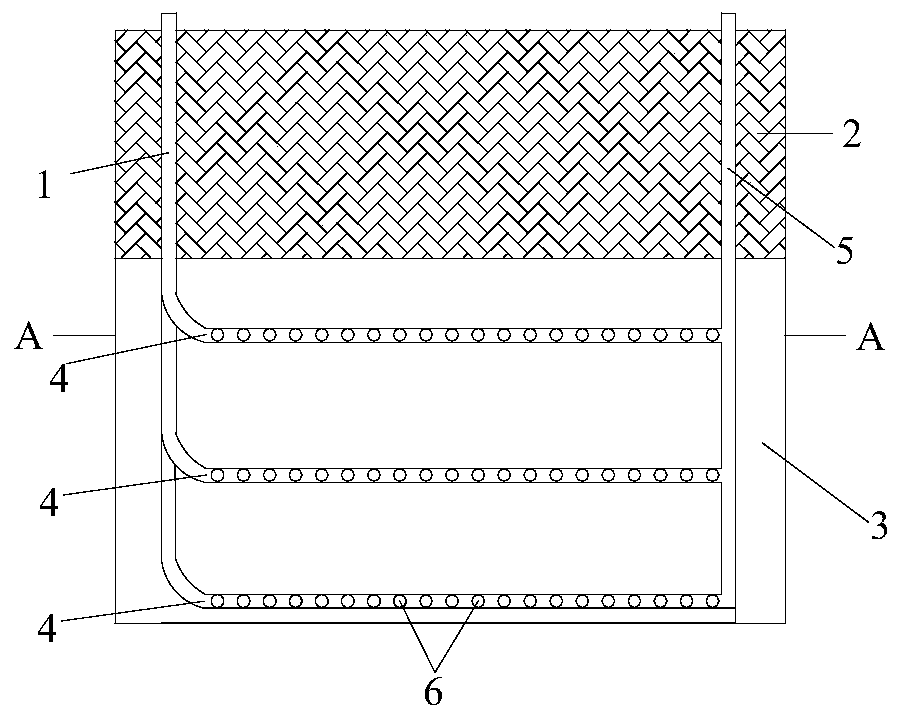

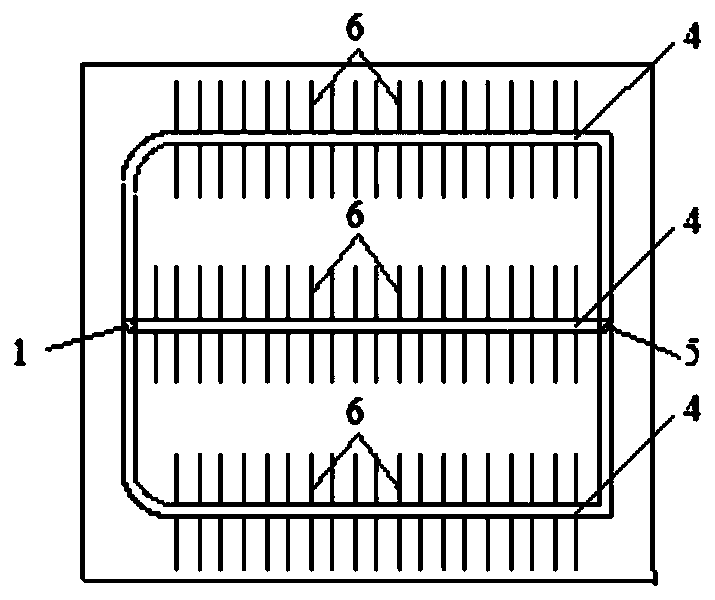

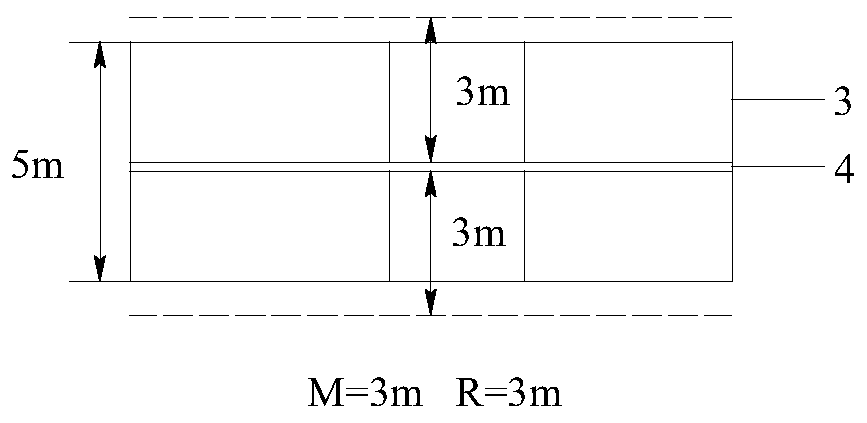

[0032] to combine figure 1 , figure 2 As shown, a deep coalbed gas thermal co-extraction method is suitable for gas drainage and geothermal energy exploitation in deep coal seams below 3000 meters, and mainly includes the following steps:

[0033] The first step is to construct the first vertical drilling 1 downwards on the surface of the mining coal field. The first vertical drilling 1 passes through the overburden of the deep coal seam and the shallow coal seam that has been mined. Heat insulation protection: while the insulation casing 2 ensures good airtightness of the wellbore, it also maintains low heat exchange with the outside world to reduce heat loss.

[0034] In the second step, after the first vertical drilling 1 reaches the deepest layer of the deep coal seam 3, the construction of each layered horizontal well 4 is carried out sequentially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com