Method for preparing 3,4-dichloro bromobenzene

A technology of dichlorobromobenzene and bromine water, which is applied in 3 fields, can solve the problems of difficult separation and purification of 3,4-dichlorobromobenzene, reduce the utilization rate of raw materials, etc., achieve good separation and purification effect, increase yield, and rationally utilize Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

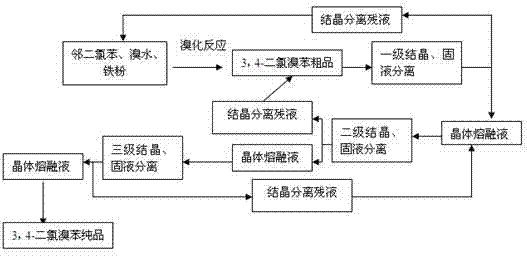

Method used

Image

Examples

Embodiment 1

[0028] Put o-dichlorobenzene and reducing iron powder into the bromination reaction kettle at a molar ratio of 1:0.02, and slowly add Br 2 , o-dichlorobenzene and Br 2 The molar ratio is 1:1.1, and the temperature is kept at 20~25°C. Waiting for Br 2 After the dropwise addition was completed, the stirring reaction was continued for 2 hours to reach the end of the reaction. After the reaction solution was washed and dried, a colorless transparent oily liquid was obtained, which was the crude 3,4-dichloro product obtained from the bromination reaction. The contents of 3,4-dichlorobromobenzene and impurity components were determined by gas chromatography. The purity of 3,4-dichlorobromobenzene in the crude product reaches 91.8%, the content of the by-product 2,3-dichlorobromobenzene is 6.7%, and the content of the reaction raw material o-dichlorobenzene is 0.7%.

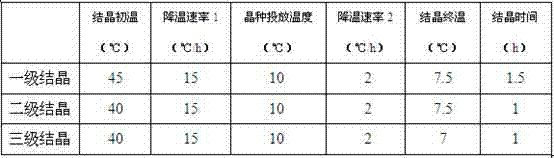

[0029] The solution crystallization of the present invention adopts the operation mode of intermittent stirring c...

Embodiment 2

[0034] By implementing the case 1 method, get the 90.1% 3,4-dichlorobromobenzene crude product of bromination gained and press the same three-stage crystallization discharge flow process, the crude product is refined, and the process conditions are as follows:

[0035]

[0036] The purity of the product obtained by the third stage crystallization reaches 99.4%, and the total crystallization yield is 80.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com