Method for preparing enoxolone

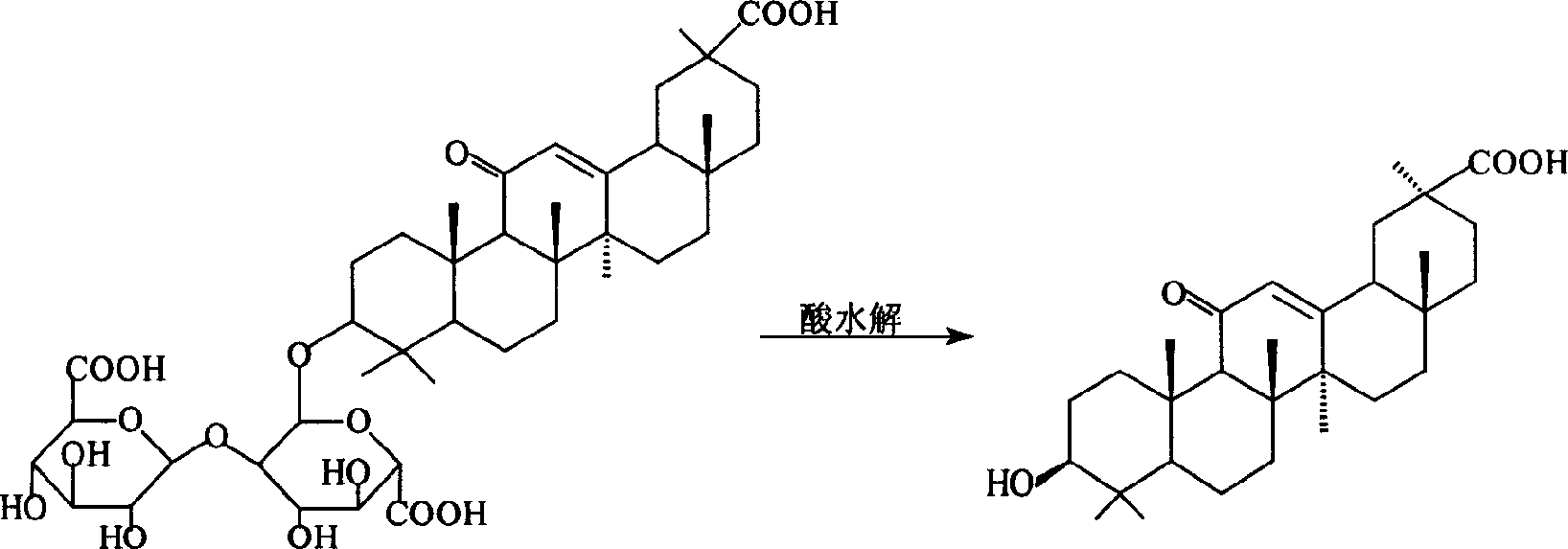

A technology of glycyrrhetinic acid and glycyrrhizic acid, applied in the direction of steroids, organic chemistry, etc., can solve the problems of difficult industrialization of preparation conditions and process technology, and achieve good separation and purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

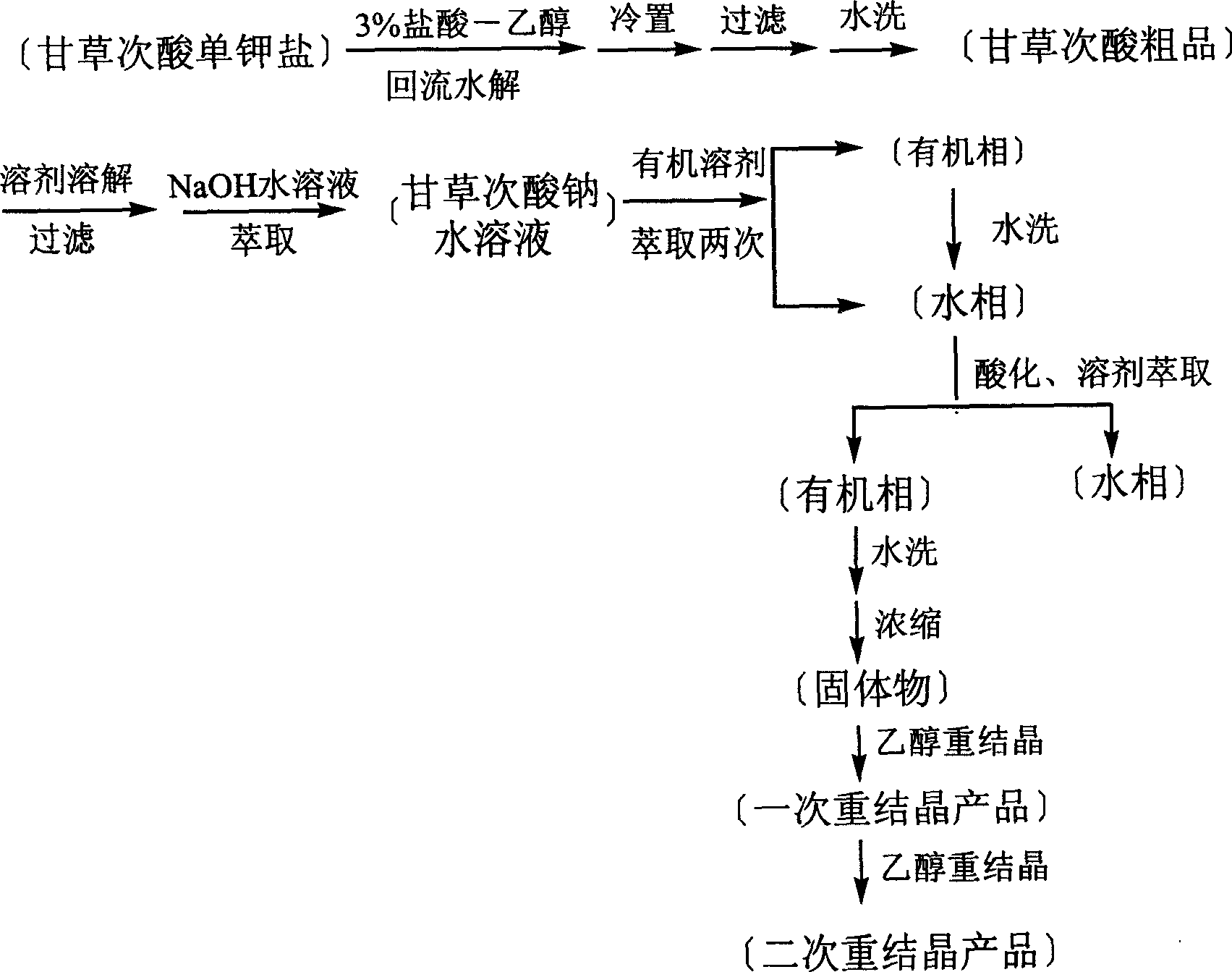

Method used

Image

Examples

Embodiment 1

[0016] Take 40g of crude glycyrrhizic acid (content about 40%), heat and dissolve with 400ml of alcohol for 4 hours, filter out insoluble impurities, adjust the pH of the filtrate to 7-8 with concentrated ammonia water, distill and recover the alcohol, dissolve the residue with 300ml of water, and pass the aqueous solution through ADS -10 macroporous adsorption resin columns (50, 50, 50ml) for three-column adsorption in series, rinse the resin column with water, combine the effluent and washing solution, add concentrated hydrochloric acid until the acid concentration of the solution is 3%, and 200ml of alcohol, heat to reflux After 6 hours, place in cold, filter the precipitated solid, wash with water, and dry in the air to obtain crude glycyrrhetinic acid. The saturated resin column is regenerated with ammonia water-ethanol solution, and the resin column can be used for the next-cycle adsorption after washing with water.

[0017] The crude product of glycyrrhetinic acid was f...

Embodiment 2

[0019] 10g monoammonium glycyrrhizinate (content about 70%), add 100ml of water and heat to dissolve, add dropwise 20ml of concentrated hydrochloric acid, add 70ml of ethanol, stir and reflux for 6 hours, cool, filter the precipitated solid, wash with water, and dry the solid , to obtain crude glycyrrhetinic acid. After further purification and recrystallization, 2.3 g of pure glycyrrhetinic acid product can be obtained. Purity 96% (HPLC method).

Embodiment 3

[0021] 100g monopotassium glycyrrhizic acid (content about 80%), after heating and dissolving with 500ml water, add 300ml ethanol, add 100ml concentrated hydrochloric acid dropwise under stirring, reflux reaction for 6 hours, place in cold place, filter the precipitated solid, wash with water, solid The mixture was dissolved in 400ml of chloroform, the insoluble solids were filtered out, extracted twice with 1mol / L NaOH aqueous solution, the aqueous phases were combined, neutralized to pH 2-3 with hydrochloric acid, and the aqueous phase was extracted twice with chloroform. The chloroform phase was washed with water, concentrated, and the residue was recrystallized with ethanol to obtain 22.3 g of a glycyrrhetinic acid product with a purity of 96%. After the second recrystallization, 18.2 g of the product was obtained. Purity ≥ 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com