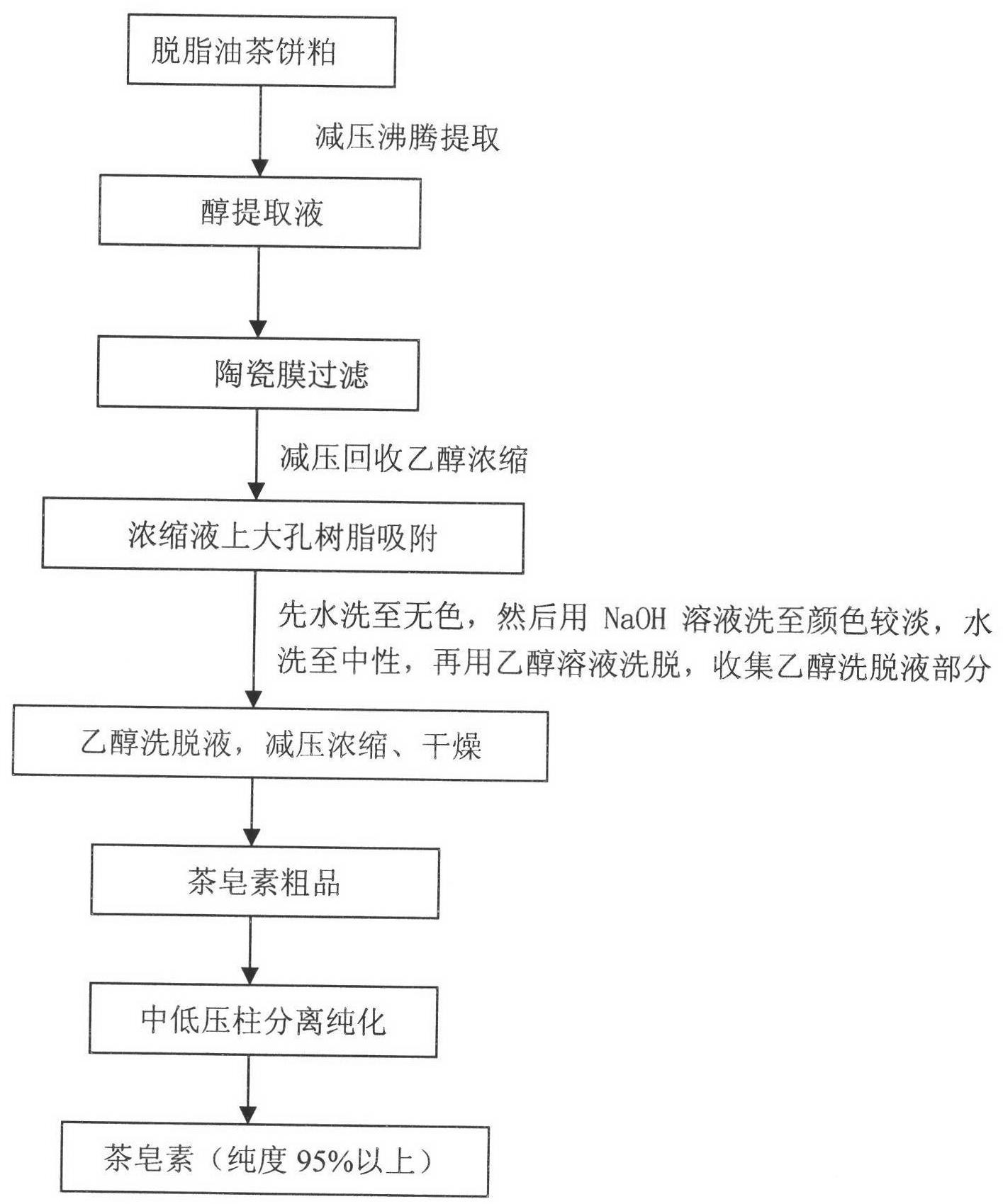

Method for extracting high-purity tea saponin from oil-tea-cake by decompression boiling

A technology of camellia oil cake and boiling under reduced pressure, applied in chemical instruments and methods, preparation of sugar derivatives, steroids, etc., can solve problems such as deep color of products, reduce the content of impurities, reduce production costs, and improve purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] HPLC Analysis Method of Tea Saponin in Camellia oleifera

[0050] Method 1: Using UV detection method

[0051] (1) Chromatographic conditions: column C 18 ODS (Φ4.6mm×200mm, 5μm), mobile phase: methanol-water (containing 0.05% glacial acetic acid) volume ratio 6:4, detection wavelength 210nm, flow rate 1ml / min.

[0052] (2) Standard curve drawing: get 0.1g of tea saponin standard substance, dissolve in 100ml volumetric flask with 80% ethanol, make tea saponin standard substance solution concentration be 1mg / ml. Take standard solutions 1, 2, 3, 4, and 5ml respectively in 10ml volumetric flasks to prepare standard solutions of 0.1, 0.2, 0.3, 0.4, and 0.5mg / ml. Using 80% ethanol solution as a blank, draw a standard curve, the standard curve equation is y=1.6658x-0.7123, r=0.9995.

[0053] (3) Determination of sample purity: Get tea saponin crude product and refined product 0.5g respectively, dissolve in 50ml volumetric flask with 80% ethanol, measure according to the ab...

Embodiment 2

[0059] vacuum extraction

[0060] Using degreased camellia oleifera cake as raw material, extracting tea saponin by boiling under reduced pressure, using 60-90% ethanol as extraction solvent, the ratio of extraction solvent to camellia oleifera cake is 1-30:1, preferably 5-15: 1. The extraction time is 4-30min, preferably 8-15min, the extraction temperature is 20-70°C, preferably 40-60°C, the extraction pressure is 0.01-0.08MPa, preferably 0.03-0.06MPa, and the extraction is 1-4 times, preferably 2 ~3 times, the extraction rate of camellia saponin is greater than 90%.

[0061] The present invention has studied the influence of extraction pressure, alcohol concentration, solid-liquid ratio and extraction time on tea saponin extraction rate, has designed 4 factors 4 levels [L 16 (4 4 )] Orthogonal test, with the extraction rate of tea saponin as an index to investigate the decompression boiling extraction process, the test results are shown in Table 1 and Table 2.

[0062] Ta...

Embodiment 3

[0068] Membrane purification process

[0069] The extract is formulated into a feed solution with a concentration of 1% to 4%, and the above feed solution is filtered with a ceramic membrane with a pore size of 0.05 μm to 0.2 μm, preferably with a membrane pore size of 0.05 μm, and an operating pressure of 0.15 to 0.3 MPa, preferably 0.15 to 0.3 MPa. 0.15MPa, the tea saponin solution passed through the ceramic membrane is decompressed and the ethanol is recovered to a solution containing 1-3g / ml of raw materials.

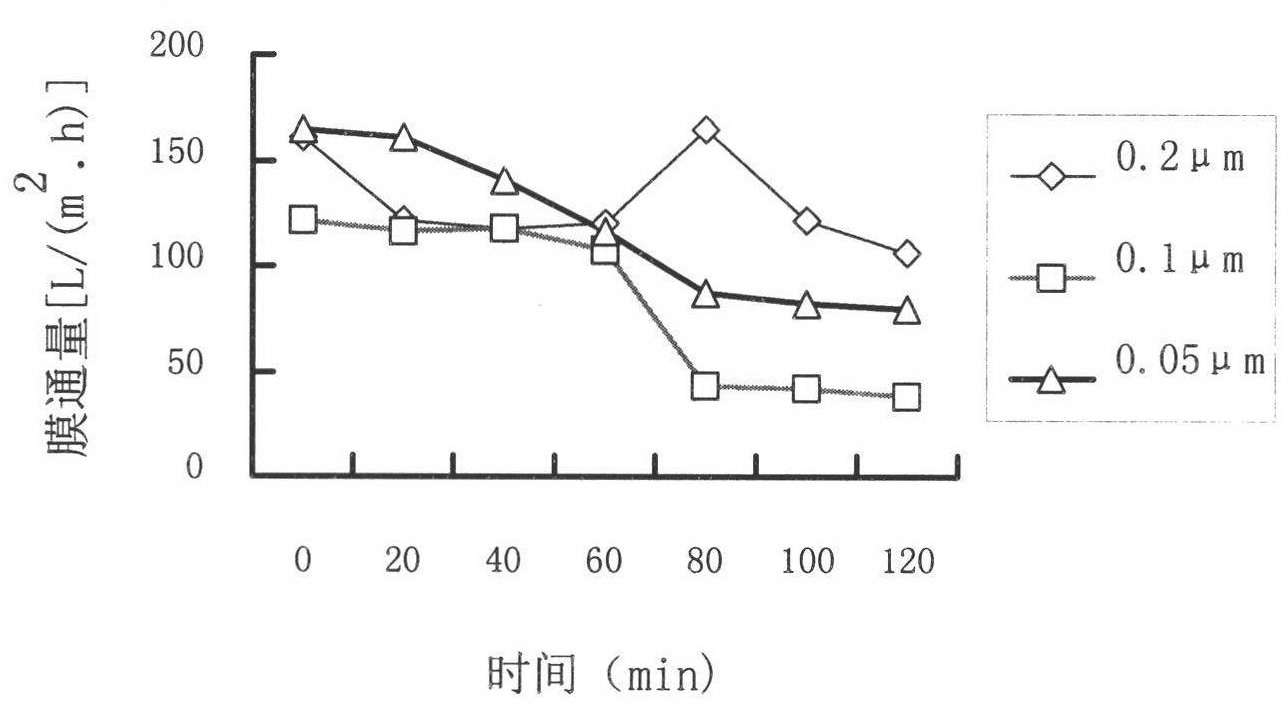

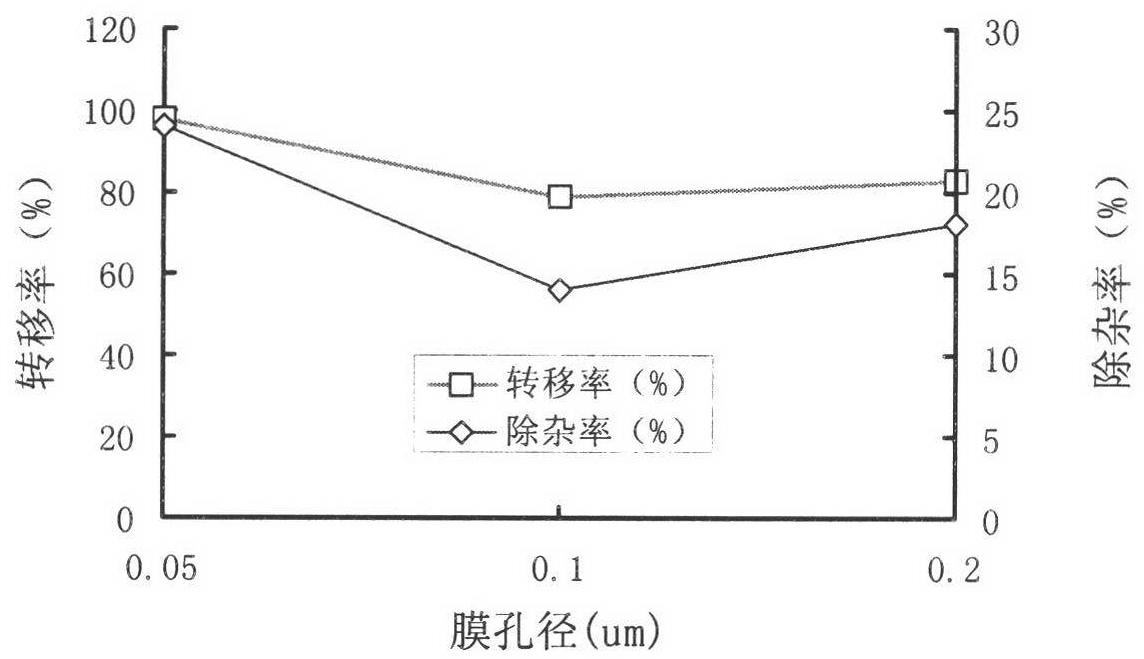

[0070] The present invention selects 0.2 μm, 0.1 μm, and 0.05 μm membrane aperture to investigate the influence of membrane aperture on membrane flux, tea saponin transfer rate and impurity removal rate, the results are as follows image 3 , Figure 4 shown. It can be seen from the figure that the membrane flux decreases to varying degrees with the extension of membrane filtration time. The results show that the membrane flux, tea saponin transfer rate and impuri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com