Radial-flow magnetic wastewater separative purification equipment

A magnetic separation and radial flow technology, applied in the field of magnetic separation, can solve the problems of equipment cost, unoptimized floor space, equipment can not operate normally, low impact load resistance, etc., to achieve good separation and purification effect, The effect of high magnet utilization and strong shock load resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

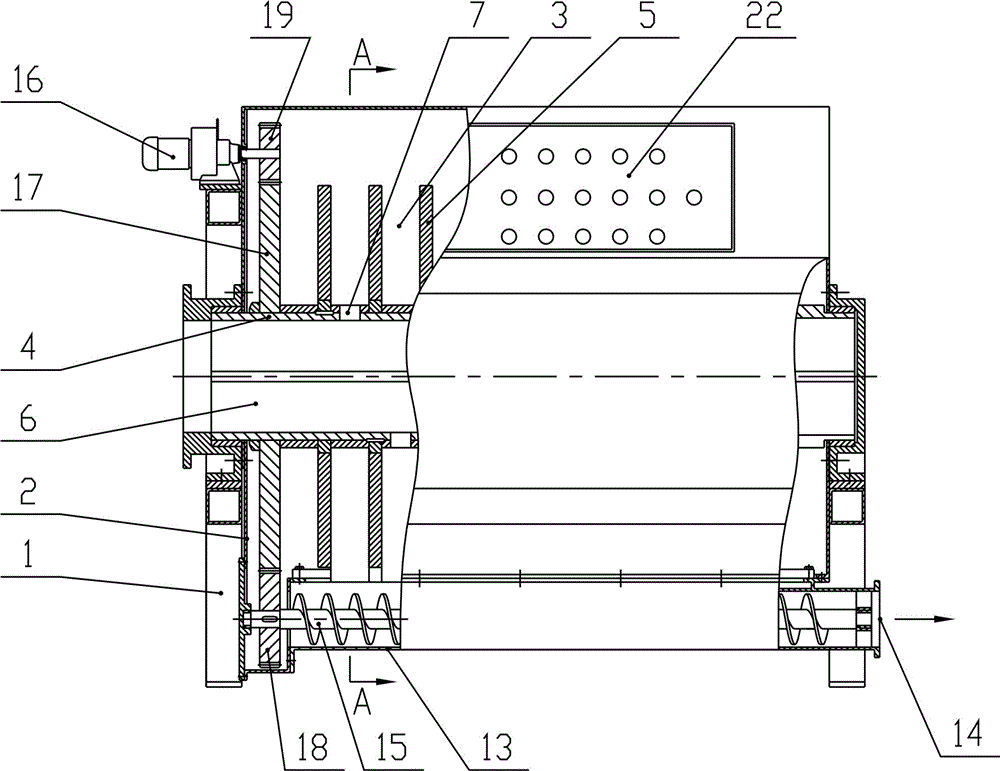

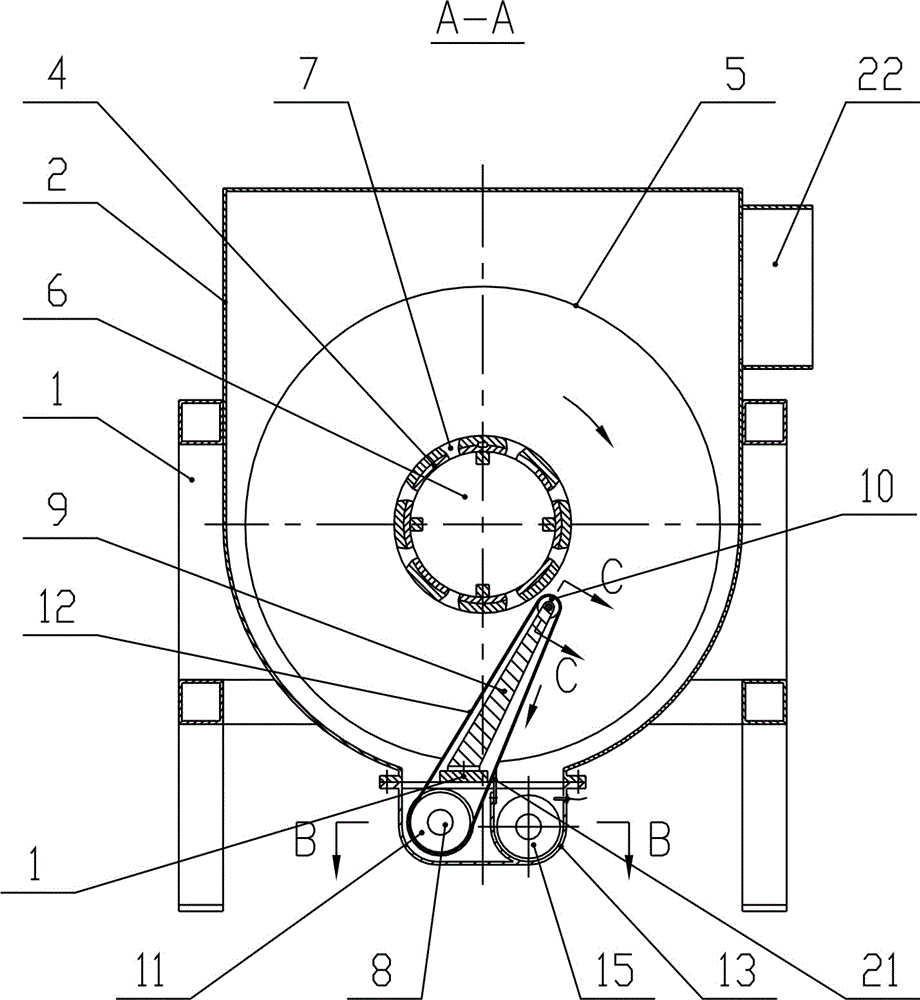

[0033] Such as figure 1 As shown, a radial flow magnetic force separation and purification wastewater equipment includes a frame 1, a water tank 2 arranged on the frame 1, a fluid interface 22 arranged on the water tank 2, a slag scraping mechanism and a transmission mechanism; a hollow shaft 4 The bearing seat is arranged in the water tank 2, and the hollow shaft 4 is provided with a number of disks 5 distributed at equal intervals; one end of the hollow shaft 4 is open, and the open end and the external pipe are a dynamic seal structure, which realizes the connection between the rotating hollow shaft 4 and the stationary The sealing fit between the external pipes; the hollow shaft 4 is arranged with a number of through holes 7 communicating with the hollow shaft cavity 6 .

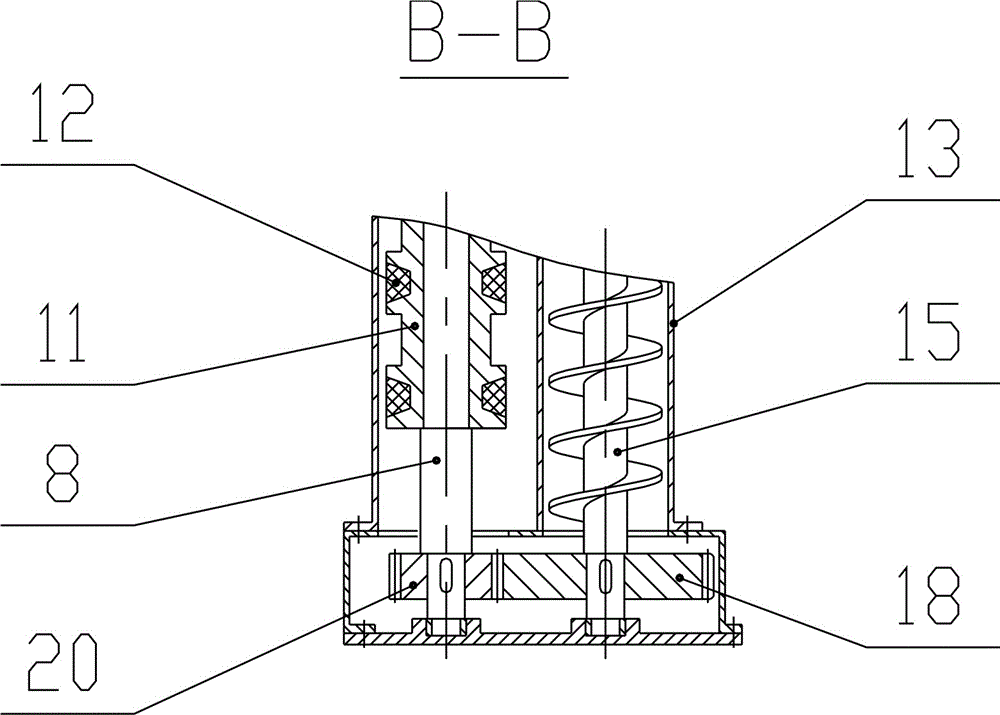

[0034] recombine figure 2 , image 3 as well as Figure 4 As shown, the slag scraping mechanism includes a slag scraping assembly and a slag conveying assembly. The slag scraping assembly is matched wi...

Embodiment 2

[0040] The structure of this embodiment is roughly the same as that of Embodiment 1, the difference is that the hollow shaft 4 is open at both ends, the two open ends and the external pipe are dynamic sealing structures, and the two ports can be used as water inlets or simultaneously as Use at the water outlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com