Permanent-magnet and turbine composite bearing

A turbo compound and bearing technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of magnetic levitation bearings, such as complex structure, small bearing capacity per unit volume, and limited application, so as to achieve enhanced relative suspension force and bearing capacity per unit volume The effect of large capacity and broadened application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

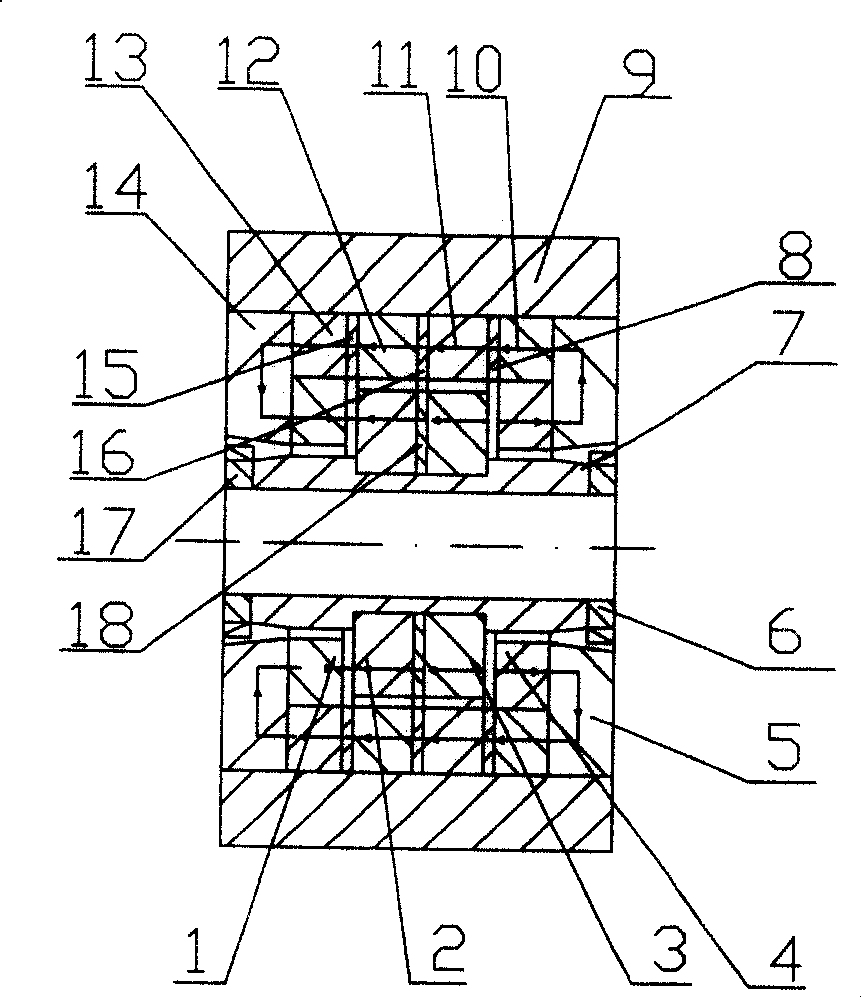

[0031] Implementation mode 1: if figure 1 As shown, the axially magnetized permanent magnet inner magnetic ring 2 and the inner magnetic ring 3 are fixed on the non-magnetic sleeve 7 of the supporting shaft. Between the inner magnetic ring 2 and the inner magnetic ring 3, there is a magnetically conductive spacer 18 of appropriate thickness, the size of its inner circle is the same as that of the inner magnetic ring, and the diameter of its outer circle is smaller than that of the inner magnetic ring on each side. One point (not shown in the figure), to strengthen the radial component magnetic force on the outer circle of the two ends of the inner magnetic ring 2 and the inner magnetic ring 3; If the magnetic force is large enough, the outer circle of the magnetic pad 18 can be made the same size as the outer circle of the inner magnetic ring. A turbine 6 and 17 are fixedly sleeved at both ends of the non-magnetic shaft sleeve 7, and the sleeve, the turbine, and the inner mag...

Embodiment approach 2

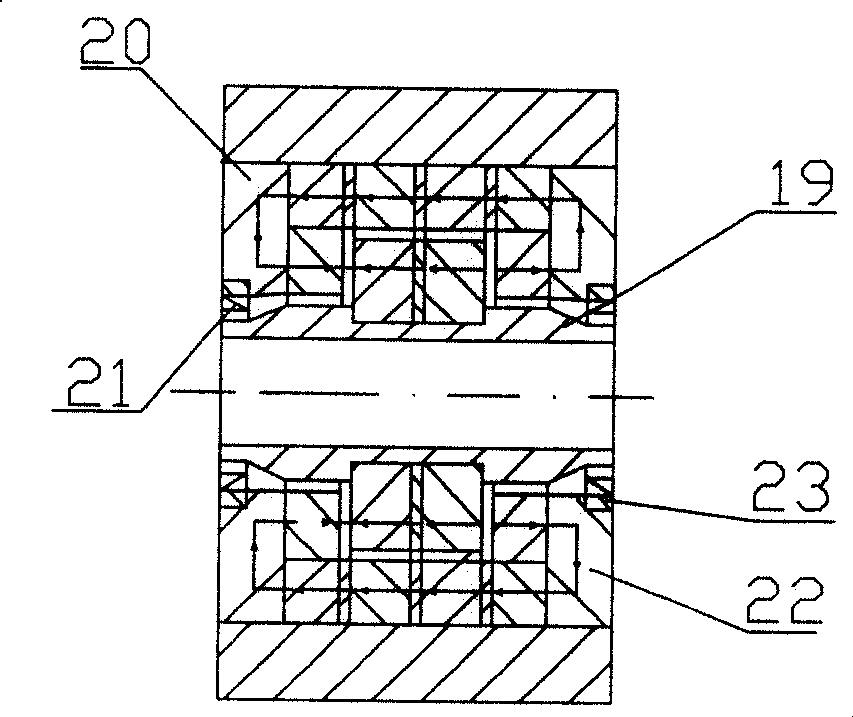

[0038] Implementation mode 2: if figure 2 Show. When the outer sleeve of the bearing needs to be rotated and the inner sleeve is fixed, the non-magnetic rotating sleeve 7, the magnetically conductive disks 5 and 14, and the turbines 6 and 17 in Embodiment 1 are correspondingly changed into figure 2 Shown non-magnetic rotating sleeve 19, magnetic conduction disk 20 and 22, turbine 21 and 23, and turbine 21 and 23 are fixedly connected with magnetic conduction disk 20 and 22 respectively, so that the inner circle of turbine 21 and 23 is in line with The outer circle of the rotating sleeve 19 is separated by a gap.

Embodiment approach 3

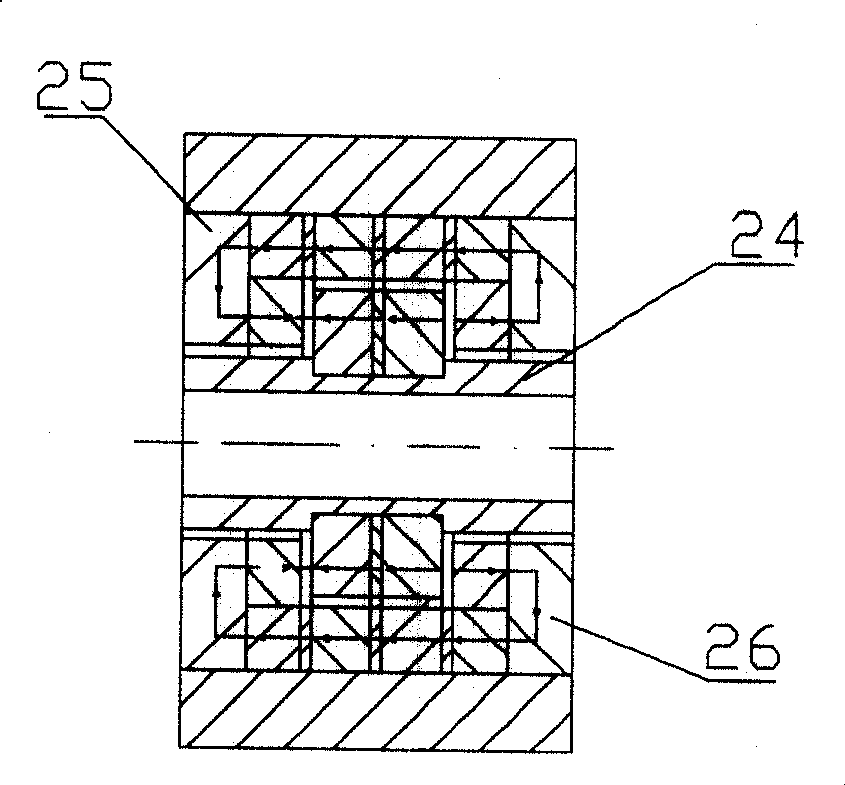

[0039] Implementation mode 3: if image 3 Show. If the rotational speed of the supported rotating shaft is low, the jumping and swinging are very small, or in a vacuum environment, then the bearing described in Embodiment 1 or 2 does not need to be equipped with a turbine, and becomes a pure permanent magnetic suspension bearing. The non-magnetic rotary sleeve 7, the magnetic conduction disk 5 and 14 in Embodiment 1 are correspondingly changed into image 3 Shown non-magnetic rotary sleeve 24, magnetic conduction disk 25 and 26.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com