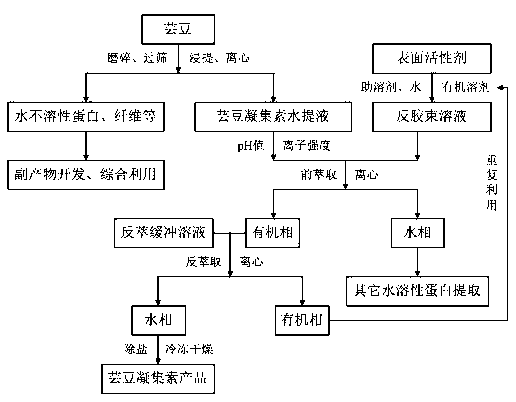

Method for microwave-assisted reverse micelle separation and purification of kidney bean agglutinin

A separation and purification, microwave-assisted technology, applied in peptide preparation methods, chemical instruments and methods, organic chemistry, etc., can solve the problems of low separation and purification ratio, multiple processes, and high cost of kidney bean lectin, and achieve easy continuous production and Effects of industrial scale-up, reduction of environmental pollution, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for separating and purifying kidney bean lectin by anionic surfactant microwave-assisted reverse micelles of the present invention specifically comprises the following steps:

[0043] (1) Preparation of kidney bean lectin aqueous extract:

[0044] Select high-quality kidney bean powder, pass through a 80-mesh sieve, dissolve in 10 times (volume) phosphate buffer solution (pH7.2, 25mM), microwave-assisted extraction at 25°C for 30min (325W), centrifuge at 12000rpm, 4°C for 20min, and take supernatant.

[0045] (2) Preparation of reverse micellar solution:

[0046] Dissolve the anionic surfactant sodium succinate-2-ethylhexylsulfonate (AOT) completely in isooctane to prepare a reverse micellar solution with a concentration of 130mM. Add a certain amount of water to the reverse micellar system W o The value is 25. In the present embodiment, the cosolvent is butanol, and the volume ratio of the cosolvent addition is 10%.

[0047] (3) Pre-extraction process:

...

Embodiment 2

[0053] A cationic surfactant microwave-assisted reverse micellar separation and purification method for kidney bean lectin of the present invention specifically comprises the following steps:

[0054] (1) Preparation of kidney bean lectin aqueous extract:

[0055] Select high-quality kidney bean powder, pass through a 80-mesh sieve, dissolve in 10 times (volume) phosphate buffer solution (pH7.2, 25mM), microwave-assisted extraction at 25°C for 30min (325W), centrifuge at 12000rpm, 4°C for 20min, and take supernatant.

[0056] (2) Preparation of reverse micellar solution:

[0057] The cationic surfactant cetyltrimethylamine bromide / cetyltrimethylammonium bromide (CTAB) was completely dissolved in isooctane to prepare a reverse micellar solution with a concentration of 150 mM. Add a certain amount of water to the reverse micellar system W o The value is 25. In the present embodiment, the cosolvent is butanol, and the volume ratio of the cosolvent addition is 10%.

[0058] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com