Magnetic adsorbent for removing Hg0 from flue gas and preparation and application of magnetic adsorbent

A magnetic adsorbent and flue gas technology, applied in the direction of gas treatment, other chemical processes, chemical instruments and methods, etc., can solve the problems of high application cost, difficult regeneration, rare adsorbents, etc., to reduce production costs, desorb Effects of high mercury efficiency and reduced usage costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Dissolve 2.51g (9mmol) FeCl in 20ml water 3 ·6H 2 O, 1.25g (4.5mmol) FeSO 4 ·7H 2 O, stir, then add 1.5 mol L -1 NH 3 ·H 2 O (10mL), the color of the solution turned black and the black solid product was precipitated to the bottom, the precipitate was washed alternately with 20ml distilled water and 20ml ethanol to remove unreacted chemical substances in the precipitate, and finally Fe was obtained 3 O 4 Nanoparticles.

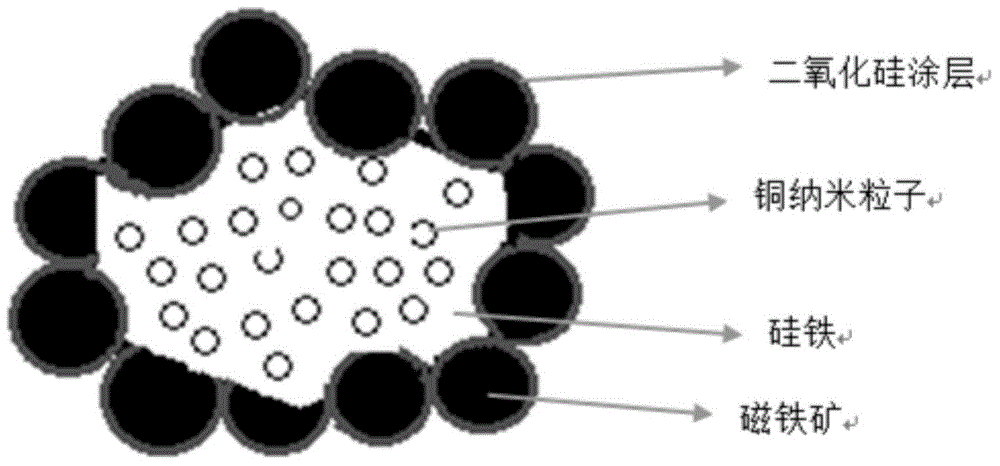

[0038] (2) The above Fe 3 O 4 Nanoparticles were placed in deionized water, added with Na 2 SiO 3 , to obtain the Si layer Fe 3 O 4 Nanoparticles, added to ethanol followed by NH 3 ·H 2 After the sol-gel reaction of O, steam treatment, and drying to obtain silica-coated magnetic particles; wherein Fe 3 O 4 Nanoparticles, Na 2 SiO 3 , ethanol, NH 3 ·H 2 The proportional relationship of O is: 1gFe 3 O 4 Nanoparticles, 10g Na 2 SiO 3 , 15mLNH 3 ·H 2 O, 10ml ethanol.

[0039] (3) uniformly stirring the copper nanoparticles and...

Embodiment 2

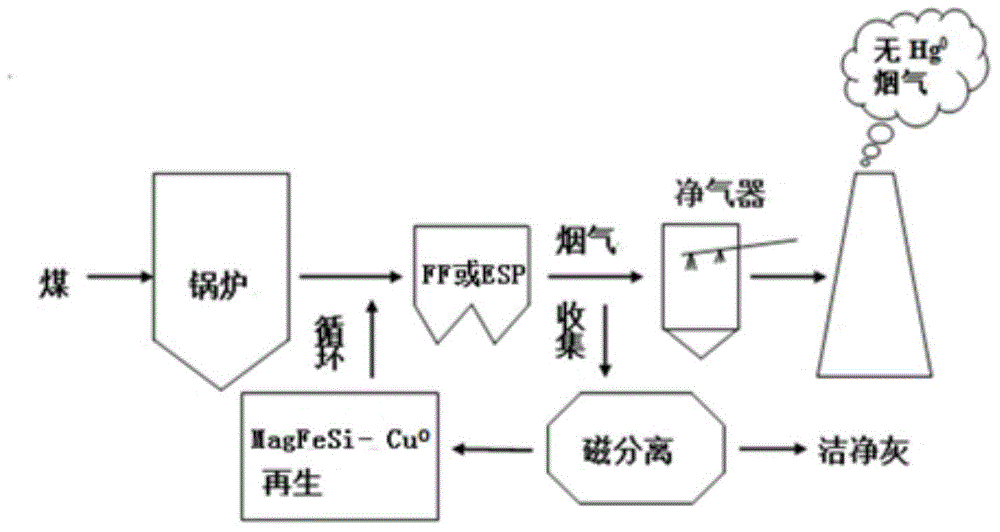

[0043] The specific production and application methods are as shown in the accompanying drawings. figure 2 As shown in the figure, the coal-fired flue gas passes through the filter material, and the mercury in the flue gas is captured by the magnetic adsorbent in the filter material, and the used adsorbent and fly ash are separated by magnetic separation, and the clean fly ash can be sold to The concrete industry, while the separated magnetic adsorbent MagFeSi-Cu 0 It will continue to be used after the regeneration cycle, so the cost of using the adsorbent will be reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com