Container type dry fermentation system

A container type, dry fermentation technology, applied in the field of dry fermentation system, can solve the problems of difficult transportation and feeding, poor mass transfer and heat transfer effect, high energy consumption, and achieve the effect of fast discharging and reducing the difficulty of feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

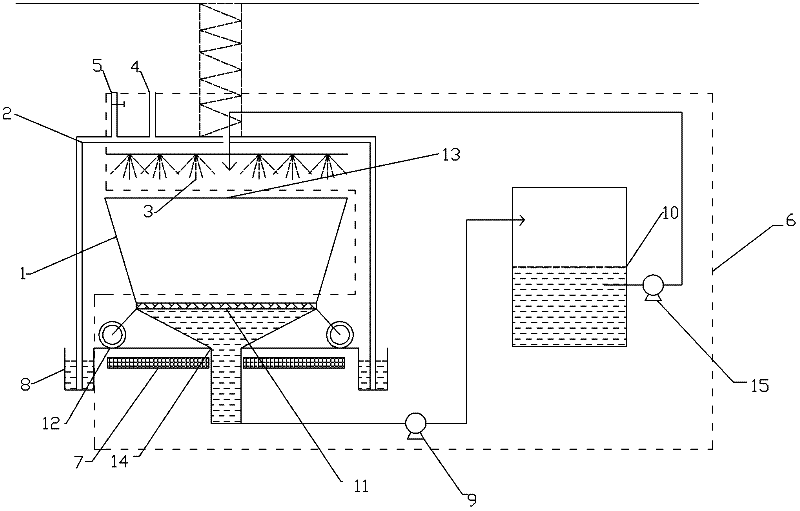

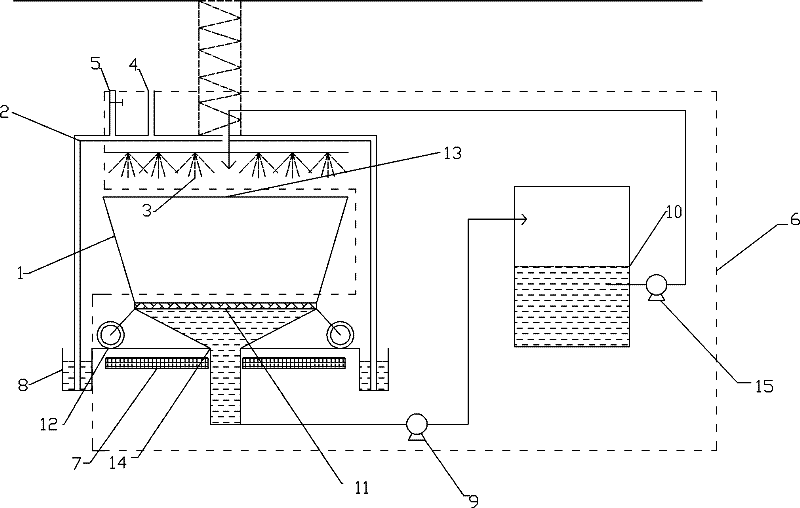

[0022] The present invention provides a container-type dry fermentation system. The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0023] Such as figure 1 As shown, the system consists of a dry fermentation device 1, a stainless steel cover 2 and a leachate circulation system 6. The dry fermentation device 1 is an inverted trapezoidal structure, supported on the base by wheels 12, the upper part is an open feed inlet 13, the bottom is an adjustable porous baffle 11, and a temperature control device is set in the base below the dry fermentation device 1. device7. The stainless steel cover 2 is covered on the dry fermentation device 1, and the top is provided with a biogas outlet 4 and a pressure safety valve 5; an annular water tank 8 is arranged around the base, and the lower edge of the stainless steel cover 2 goes deep into the water tank 8 to play a sealing effect . The top of the stainless stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com