Composite filler tower for extracting oil-water system

A composite, packed tower technology, applied in liquid solution solvent extraction and other directions, can solve the problems of poor droplet breakup and low mass transfer efficiency, and achieve the effect of efficient mass transfer and improved mass transfer efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

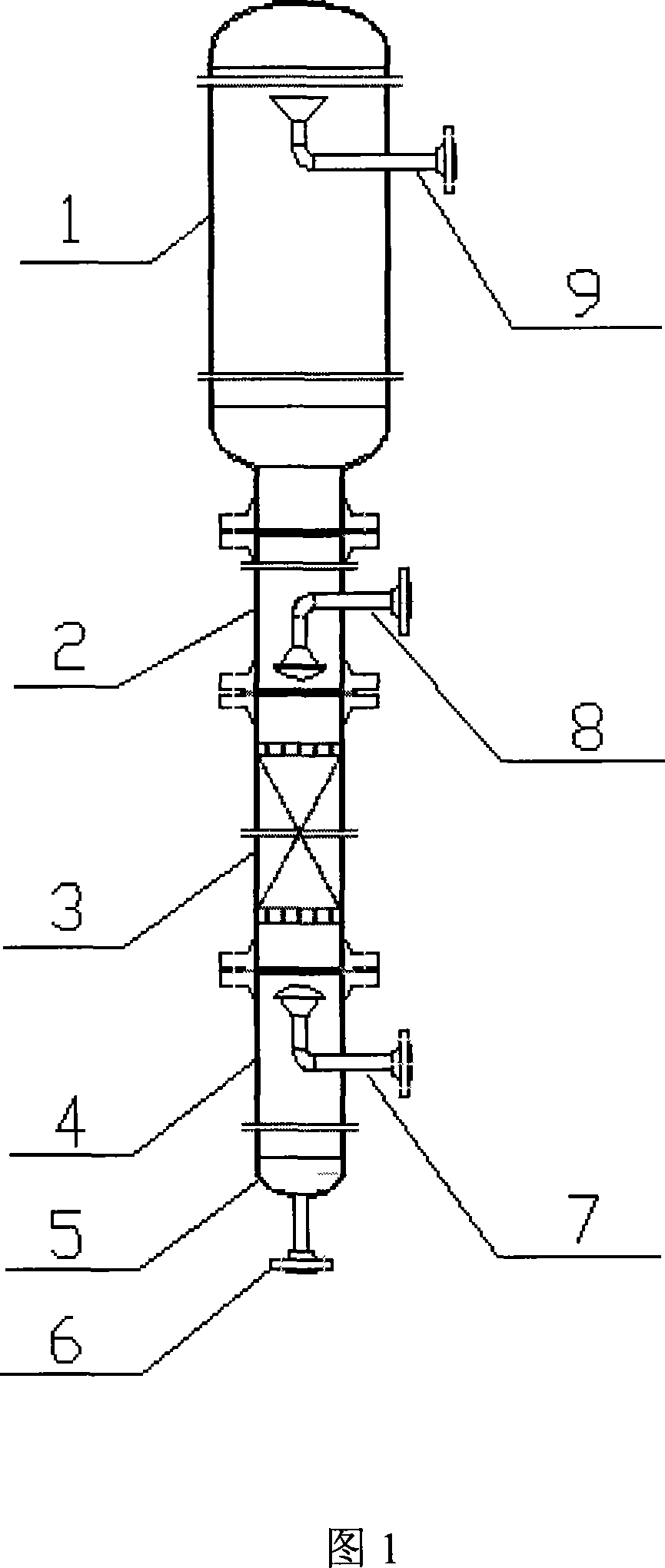

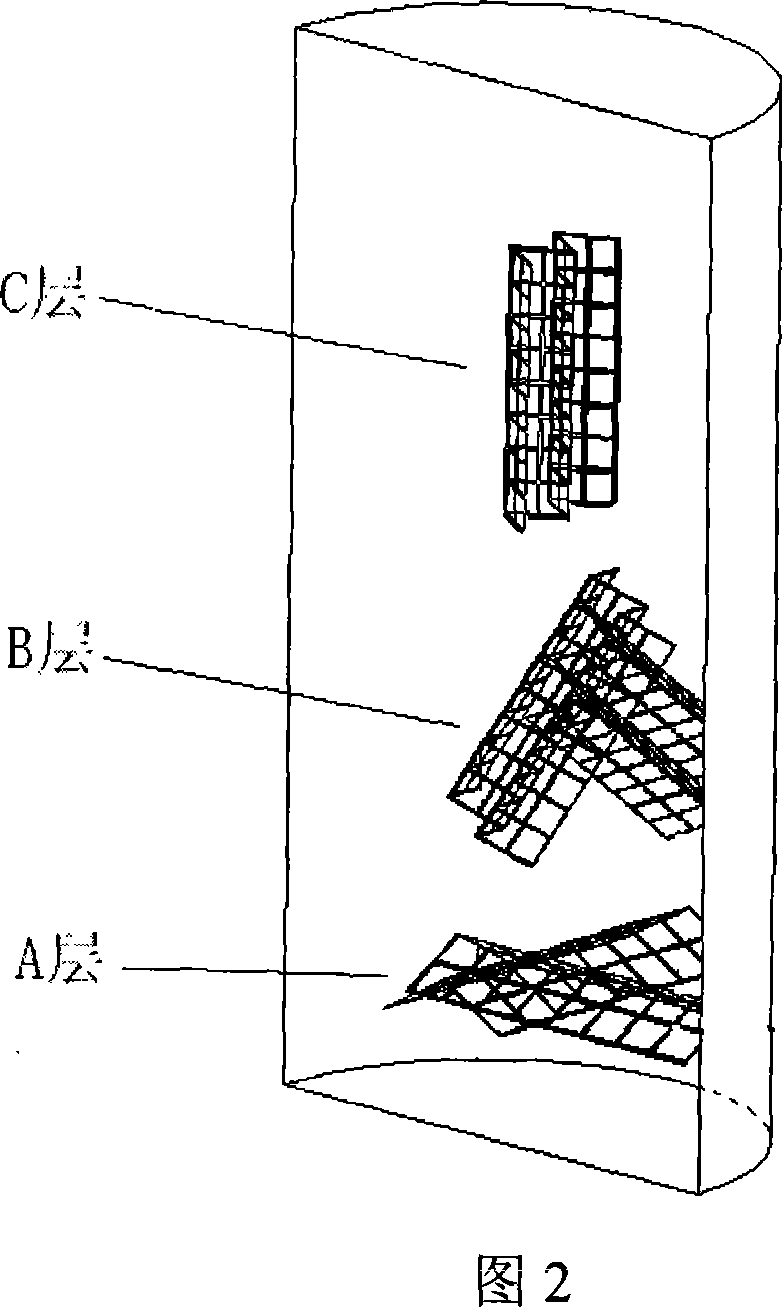

[0012] Below in conjunction with accompanying drawing the present invention is described in detail through the embodiment: adopt the extraction composite packing tower of kerosene (containing 30% tributyl phosphate)-acetic acid-water system to extract acetic acid in water with kerosene. The structure diagram of the extraction composite packed tower is shown in Figure 1. The total height of the extraction composite packed tower is 3000mm; the clarification section 1 is 600mm high and has an inner diameter of 110mm. It is equipped with a light phase outlet 9, and the outlet position is 150mm away from the top of the tower; the heavy phase feed Section 2 and light phase feed section 4 are both 400mm high, and a heavy phase distributor 8 and a light phase distributor 7 are respectively installed in the middle of the two feed sections. The diameter of the head disc is 60mm, and 26 small holes with a diameter of 1.5mm are evenly distributed; below the heavy phase feed section 2 is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com