Hybrid dry cooler heat exchange with water-droplet slit and water-droplet splitting louver for heat exchangers with primarily latent heat transfer

a technology of heat exchangers and dry coolers, which is applied in the direction of trickle coolers, stationary conduit assemblies, tubular elements, etc., can solve the problems of significant increase in the surface wet with water and noticeable increase in the latent heat transfer through evaporation, so as to improve the efficiency of mass transfer during wetting, increase the percentage of wetted surfaces relative to the entire heat exchange surface, and improve the effect of cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

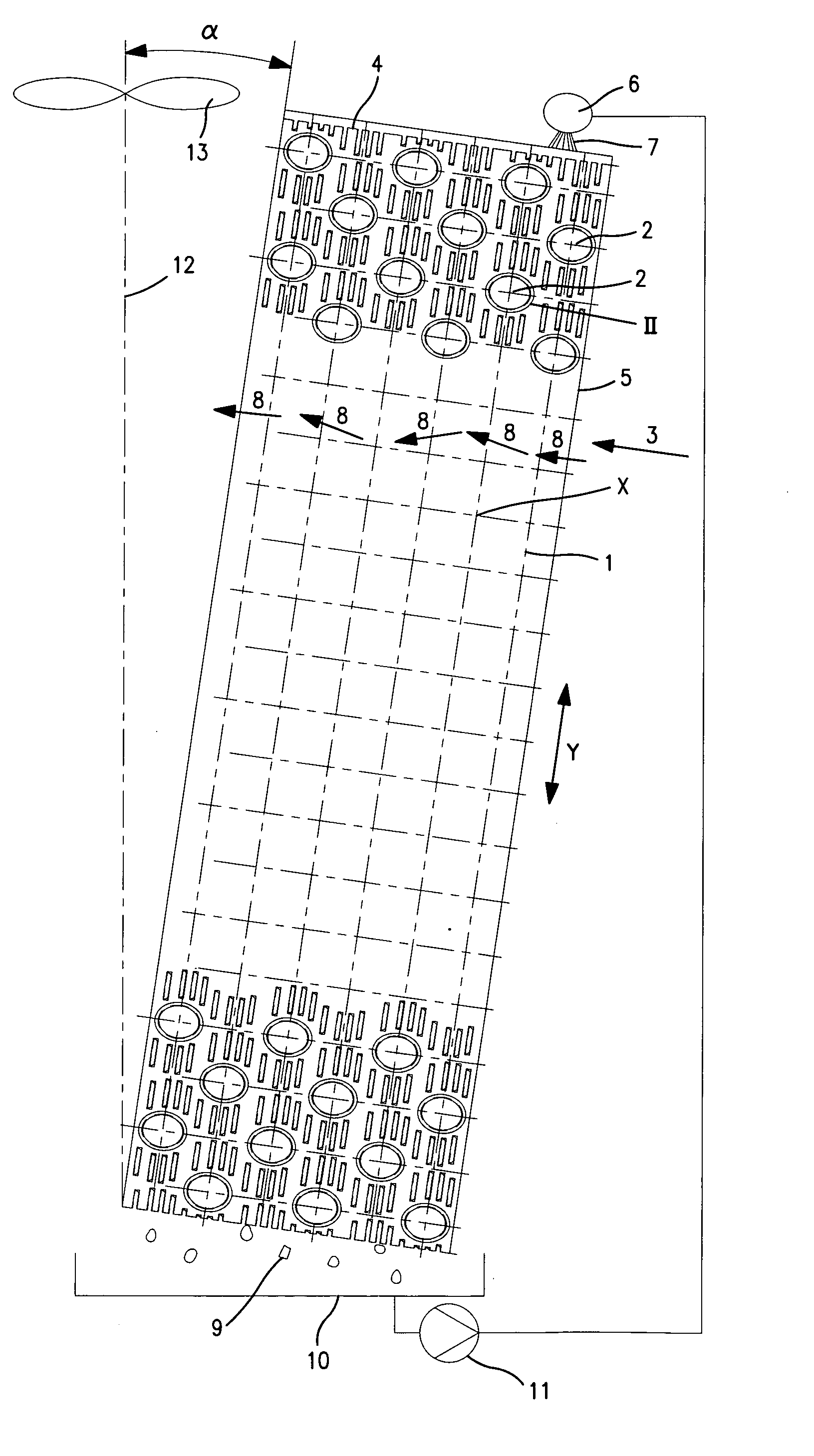

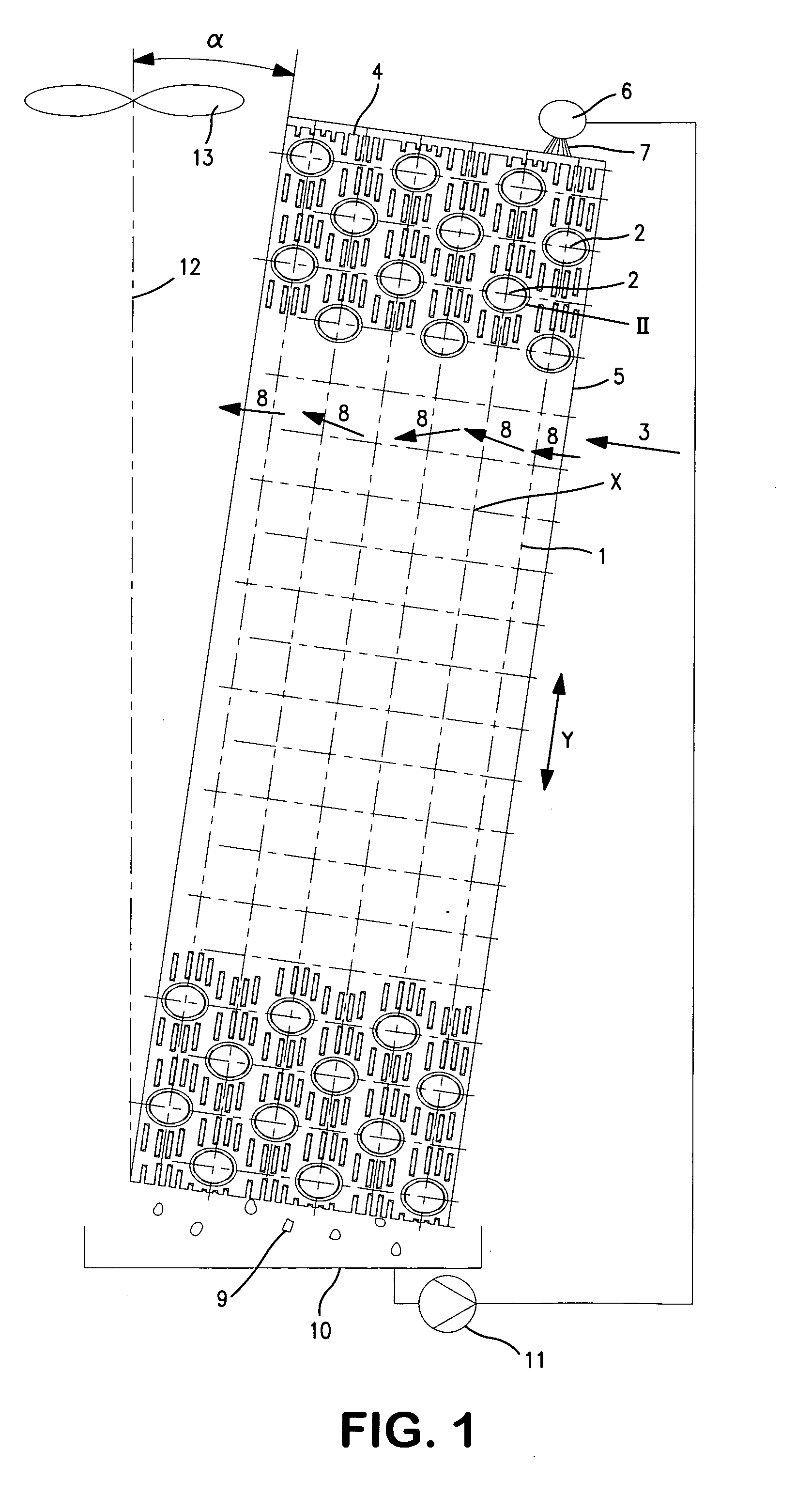

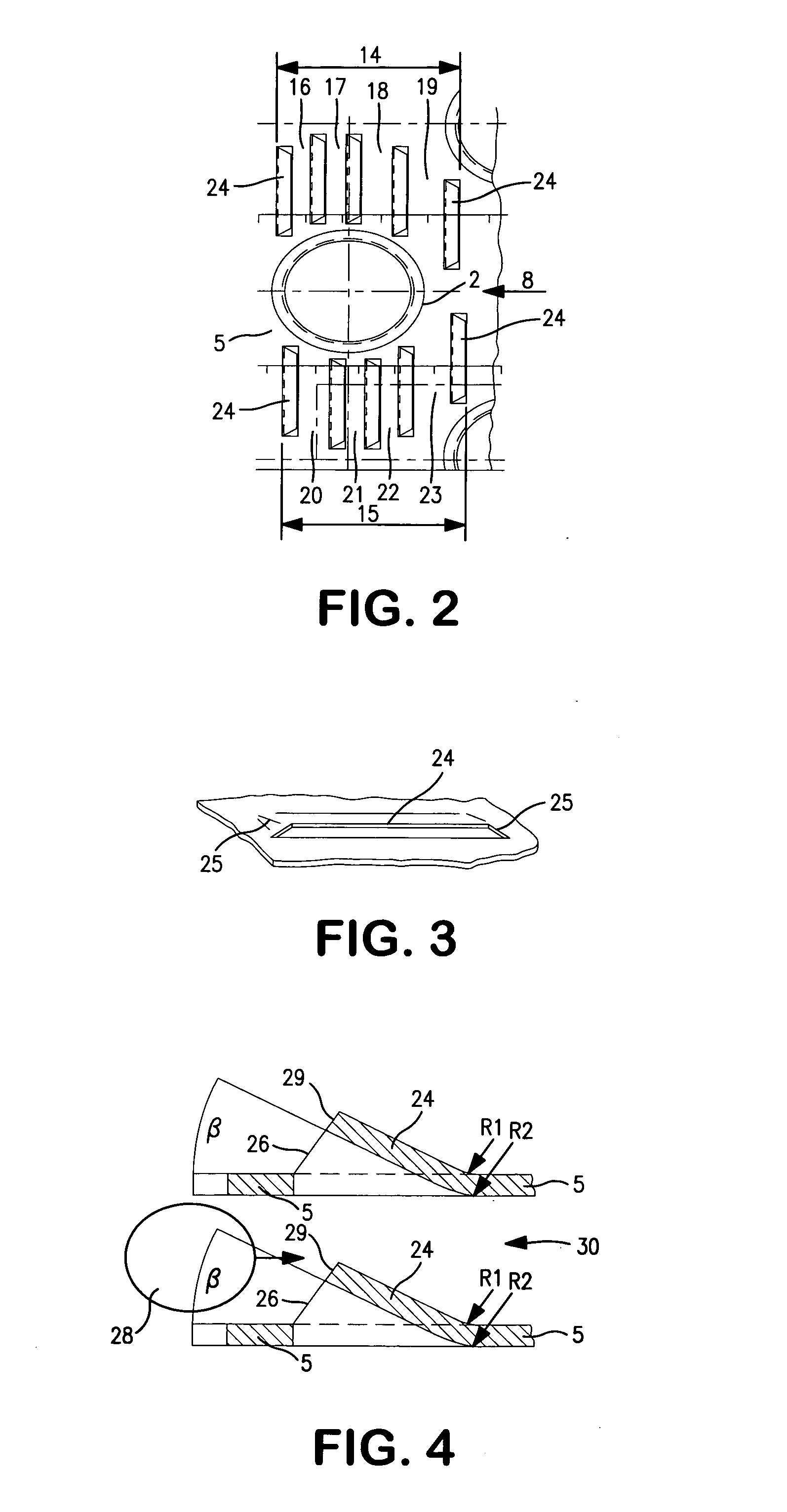

[0028]FIG. 1 shows a hybrid heat exchanger 1 with several tubes 2 which run parallel to each other and are arranged at a selected distance from each other. The tubes 2 are positioned horizontally. The tubes 2 begin and end in so-called collectors, not shown in FIG. 1. A liquid flows inside the tubes 2. The temperature of the liquid which must lie above that of the wet-bulb temperature of the surrounding air.

[0029]Along the reach of the fin depth in the air flow direction 3,8, the tubes 2 may be arranged behind each other or preferably offset. In accordance with the number of tube rows, the liquid can flow through the heat exchanger one to several times.

[0030]The feed 6 of the wetting water 7 is located above the upper face 4 of the fins 5. A larger quantity of this water is output than can evaporate in the air stream 8. The excess wetting water 9 is collected in a catch bowl 10 and recirculated via a pump 11.

[0031]In accordance with the preferred embodiment, the heat exchanger 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com