Three-dimensional graphene nanoribbon/carbon nanoribbon bridged structural material, and preparation method and application thereof

A technology of graphene nanobelts and carbon nanotubes, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of reduced lithium storage space in batteries, poor stability of lithium batteries, and easy structure of GNRs. collapse and other problems, to achieve the effect of enhanced lithium storage capacity, good electrical conductivity and mechanical properties, sufficient electron transport and mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Take 10 mL of 0.5 mg / mL carboxylated carbon nanotube solution, add 100 uL of pyrrole as a N source, and disperse ultrasonically until a uniform suspension is formed1.

[0049] (2) The suspension 1 was sealed in a 15 mL hydrothermal reactor, and placed in an oven at 180 °C for 12 h to obtain a block-shaped carbon nanotube hydrogel.

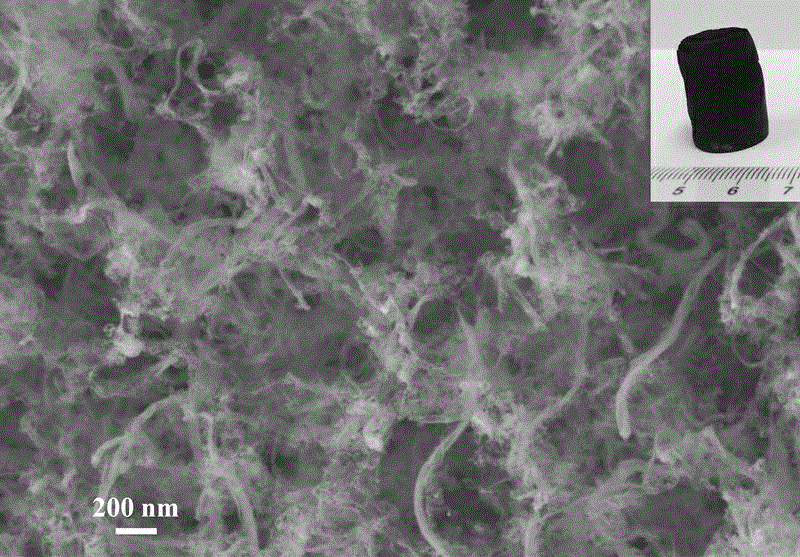

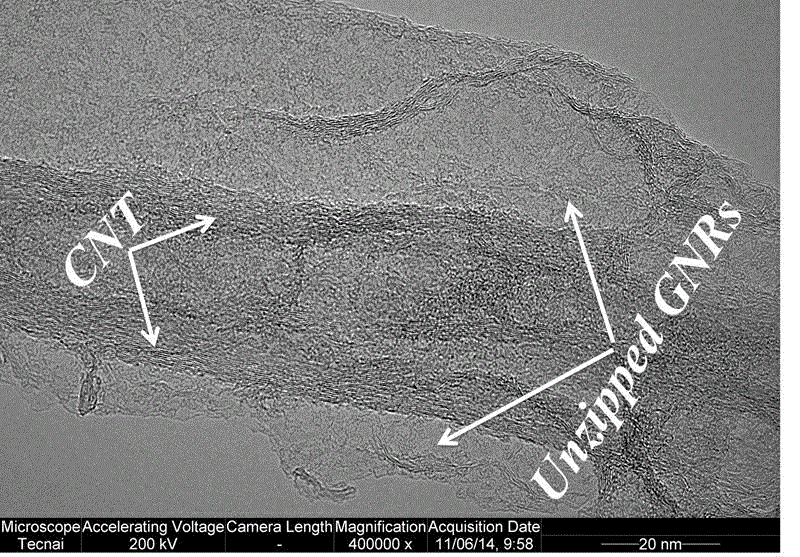

[0050] (3) Put the pre-obtained carbon nanotube hydrogel in 2 M KNO 3 Solvent replacement was carried out in the solution for 24 h. After the replacement was complete, the hydrogel was taken out and sealed in a 15 mL hydrothermal reactor, and then placed in an oven at 180 °C for 48 h to obtain the GNRsCNT hydrogel.

[0051] (4) Replace the obtained hydrogel in 1L of water to wash away the residual impurities (KNO 3 And its reaction by-products), pour out the distilled water after 10h of replacement, repeat 6-8 times. Then, the washed hydrogel was replaced in 500 mL of tert-butanol, and the tert-butanol was poured out after 10 hours of ...

Embodiment 2

[0054] (1) Take 15 mL of 10 mg / mL carboxylated carbon nanotube solution, add 1 mL of thiophene as S source, and ultrasonically disperse until a uniform suspension is formed.

[0055] (2) The suspension 2 was sealed in a 20 mL hydrothermal reactor, and placed in an oven at 200 °C for 6 h to obtain a block-shaped carbon nanotube hydrogel.

[0056] (3) Put the pre-obtained carbon nanotube hydrogel in 1 M K 2 SO 4 The solvent was replaced in the solution for 48 h. After the replacement was complete, the hydrogel was taken out and sealed in a 20 mL hydrothermal reactor, and then placed in an oven at 180 °C for 36 h to obtain the GNRsCNT hydrogel.

[0057] (4) Replace the obtained hydrogel in 1 L of distilled water to wash away the residual impurities (K 2 SO 4 and its reaction by-products), pour out the distilled water after replacement for 10 h, repeat 6-8 times. Add acetone to the hydrogel, pour out the acetone after soaking for 10 h, and repeat 4 times to obtain a ketone gel...

Embodiment 3

[0060] (1) Take 30 mL of 15 mg / mL carboxylated carbon nanotube solution, add 3 mL of pyrrole and 3 mL of thiophene as N and S sources, and disperse ultrasonically until a uniform suspension is formed3.

[0061] (2) The suspension 3 was sealed in a 50 mL hydrothermal reactor, and placed in an oven at 140 °C for 24 h to obtain a block-shaped carbon nanotube hydrogel.

[0062] (3) Put the pre-obtained carbon nanotube hydrogel in 1 M KNO 3 Solvent exchange was carried out in the solution for 48 h. After the replacement was complete, the hydrogel was taken out and sealed in a 50 mL hydrothermal reactor, and then placed in an oven at 180 °C for 60 h to obtain the GNRsCNT hydrogel.

[0063] (4) Replace the obtained hydrogel in 1L of water to wash away the residual impurities (KNO 3 And its reaction by-products), pour out the distilled water after 10h of replacement, repeat 6-8 times. Then add ethanol to the hydrogel, pour out the ethanol after soaking for 5 h, repeat 4 times, add ...

PUM

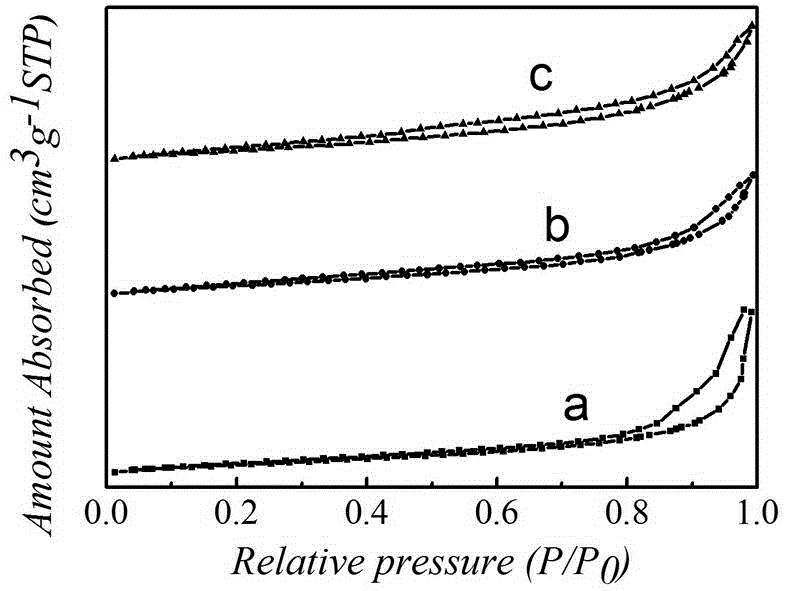

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com