Inner loop reactor with reacting and separating functions

一种反应器、内环流的技术,应用在化学/物理/物理化学反应器的详细信息、化学仪器和方法、化学/物理过程等方向,能够解决无法起到混合和分离过程强化、流程复杂、费时等问题,达到传热效果保持良好、减少占地面积、扩展适用范围的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

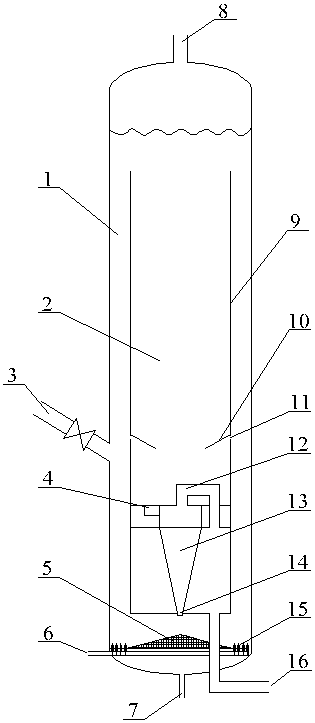

[0023] like figure 1 As shown, the gas enters the riser of the inner loop reactor through the gas-liquid integrated distributor (15) from the annular gap, and the liquid flows from the riser (1) to the downcomer (2) driven by the gas. There is a sealed structure between the cylindrical section of the hydrocyclone (13) and the inner wall of the downcomer (2), and all materials enter the hydrocyclone (13) horizontally and tangentially from the inlet (4) of the hydrocyclone, and are separated Finally, the slurry containing solid catalyst particles is discharged from the bottom flow port (14) of the hydrocyclone, and the inner member (5) of the anti-flow dead zone can effectively prevent the accumulation of catalyst particles at the bottom flow port (14) of the hydrocyclone And lead to the riser, so as to ensure that the catalyst can be fully recycled. The reacted product is discharged as a light phase from the overflow port (12) through the hollow structure between the hydrocycl...

Embodiment 2

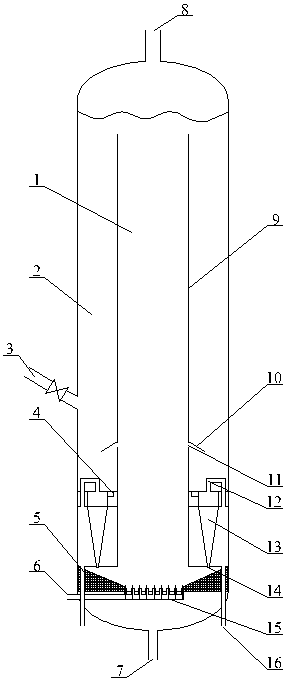

[0025] In this embodiment, the gas enters the riser of the inner loop reactor from the inner cylinder through the gas-liquid integrated distributor (15), and the liquid flows from the riser (1) to the downcomer (2) driven by the gas. There is a sealed structure between the cylindrical section of the hydrocyclone (13) and the inner wall of the downcomer (2), and all materials enter the hydrocyclone (13) horizontally and tangentially from the inlet of the hydrocyclone (4), preventing flow The inner member (5) in the dead zone can effectively prevent catalyst particles from accumulating at the lower part of the hydrocyclone bottom flow port (14) and guide them to the riser, thereby ensuring that the catalyst can be recycled. After separation, the slurry containing solid catalyst particles is discharged from the bottom outlet (14) of the hydrocyclone, and enters the riser again for the next cycle. The reacted product is discharged as a light phase from the overflow port (12) throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com