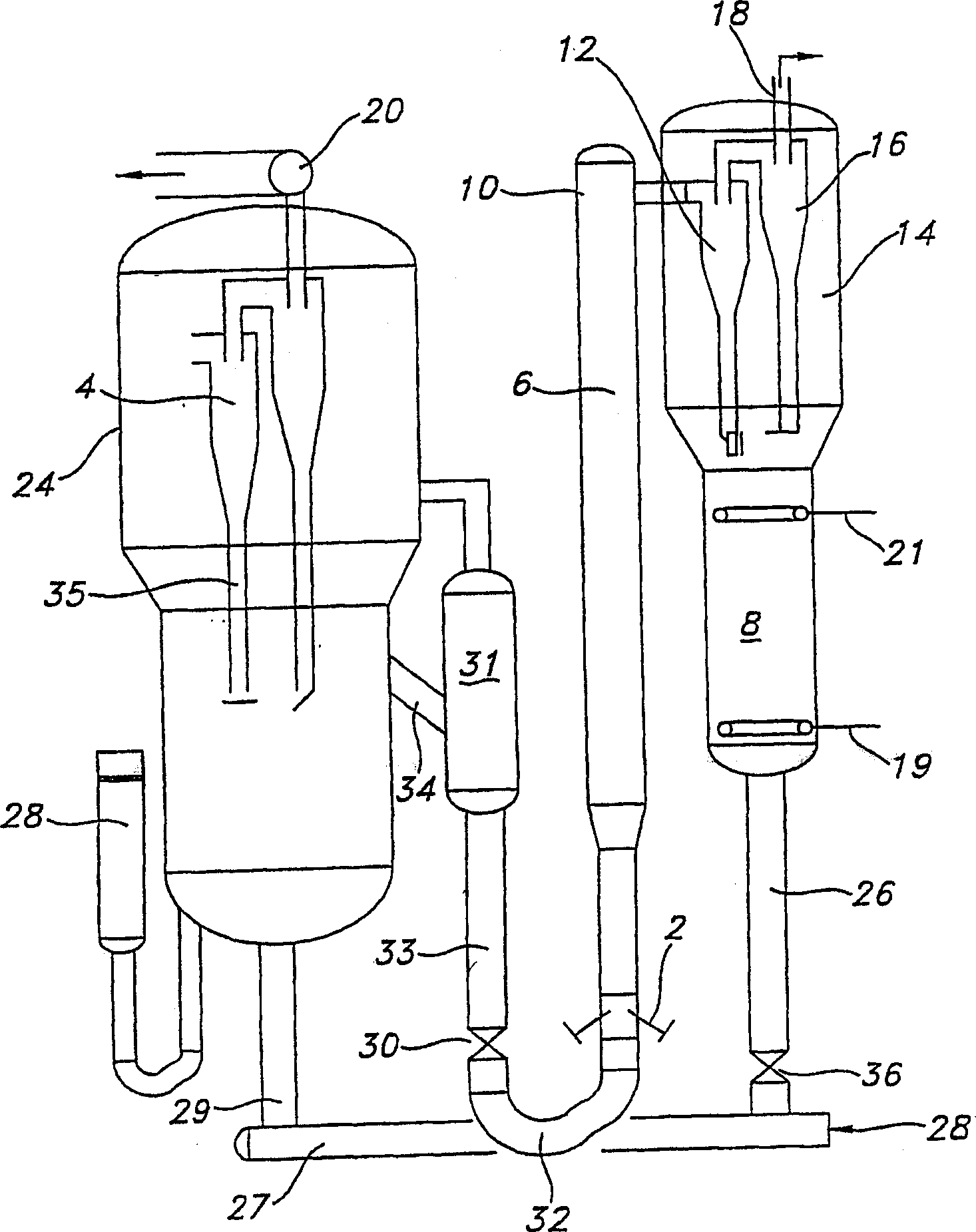

Apparatus for countercurrent contacting of gas and solids

A countercurrent contact and equipment technology, applied in the field of stripping towers, can solve the problems of reduced efficiency and mass transfer efficiency, and achieve the effect of avoiding channeling and effective mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

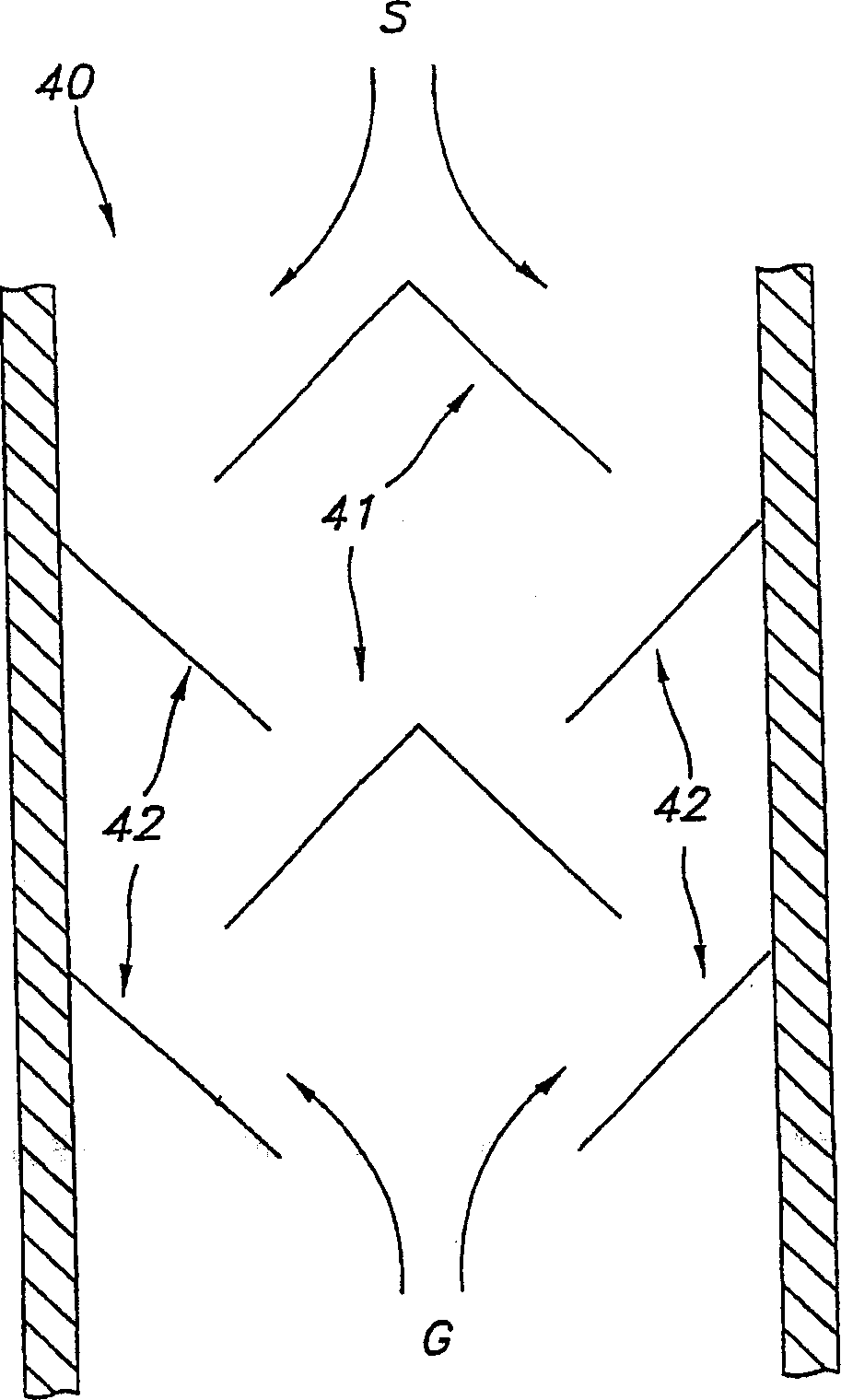

Method used

Image

Examples

example

[0033] The relationship between capacity and efficiency has been seen experimentally by cold flow tests. The cold flow model experiments used actual catalyst and air to simulate the actual operation of an industrial FCC stripper. Tests were conducted to study the performance of prior art strippers and new equipment. In the experiment, the fluidized catalyst was injected with helium tracer gas before entering the stripper. The descending catalyst particles are contacted with the ascending gas. The ability to remove this tracer gas was measured over a range of catalyst flow rates and under a variety of equipment configurations and conditions. Samples were obtained at various points in the inlet and outlet of the stripper and in the height of the stripper, and these samples were analyzed for helium concentration.

[0034] Figure 10 shows the measured performance of the apparatus of the present invention using the new baffle arrangement compared to the performance of an existin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com