Integrated reactor suitable for purifying and impurity-removing of pyrolusite leachate

A technology for purifying and removing impurities and a reactor, which is applied in the direction of improving process efficiency, can solve the problems of increasing infrastructure and operating costs, multi-power consumption, and not easy to settle, and achieves the improvement of filtrate discharge water quality, processing capacity, and filtrate turbulence. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

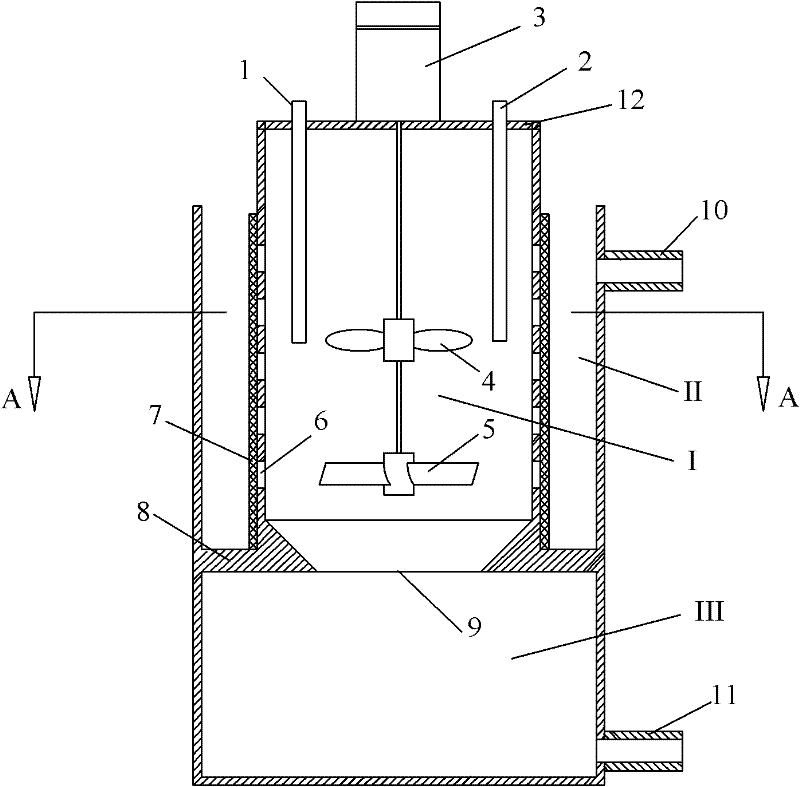

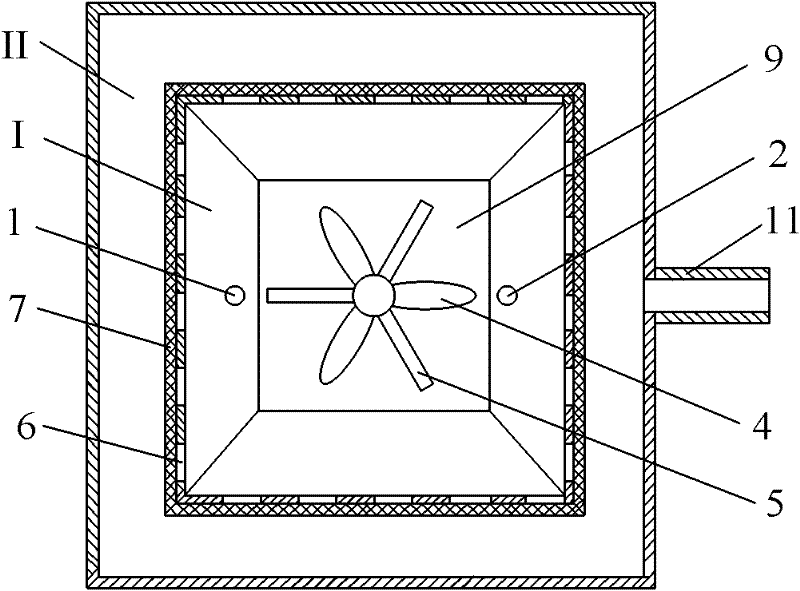

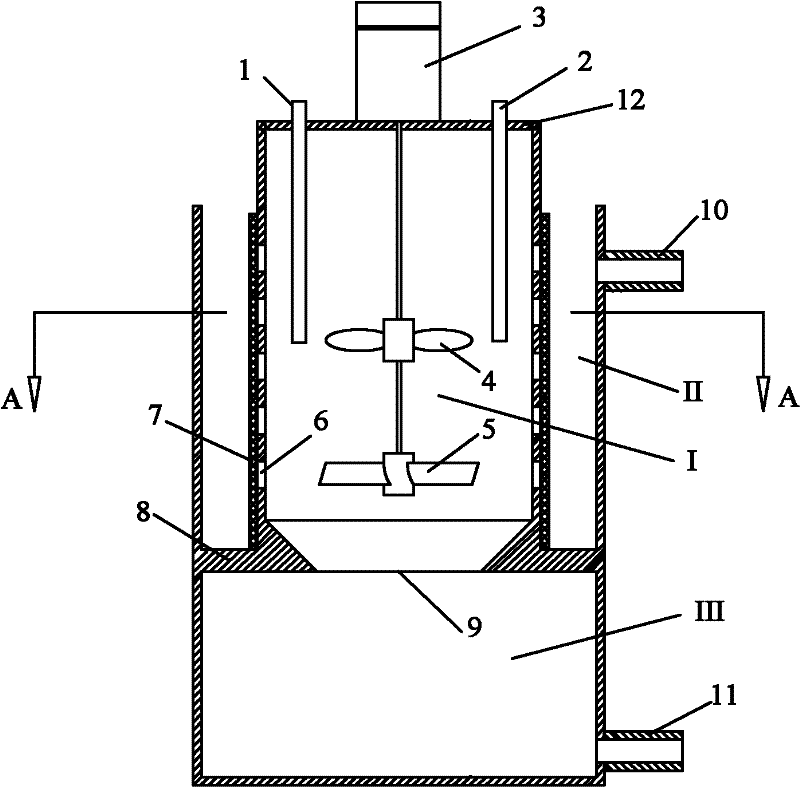

[0026] The integrated reactor suitable for purification and impurity removal of pyrolusite leaching solution in this embodiment has a structure as attached figure 1 And attached figure 2shown. The reactor cylinder is divided into upper and lower parts by the separation layer member 8 arranged in the cylinder. The upper part of the space is the main reaction zone I and the filtrate zone II, and the lower part of the space is the precipitation separation zone III. Among them, the main reaction zone I and the filtrate zone Zones II are separated by filter layer members fixedly arranged on the separation layer member 8 . The filter layer member is composed of a filter membrane layer 7 fixed on a cylindrical frame 6 and arranged parallel to the reactor cylinder. The partition member is designed with a channel 9 connecting the main reaction zone I and the precipitation separation zone III, and the channel connecting the main reaction zone I and the precipitation separation zone I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com