Bleed-out forecasting method and system based on least squares

A technology of least squares and steel breakout, which is applied in the field of least squares-based steel breakout prediction method and system, and can solve problems such as early warning of steel breakout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of one or more embodiments. It may be evident, however, that these embodiments may be practiced without these specific details.

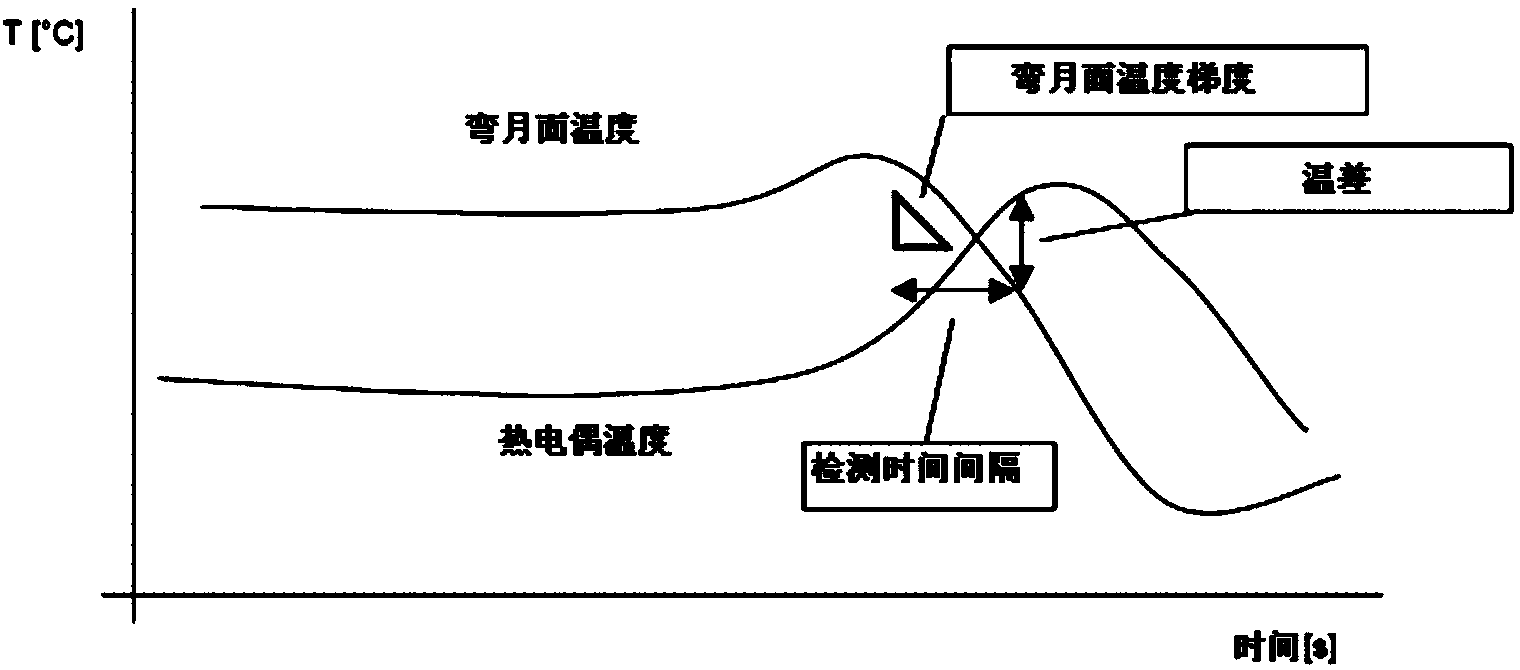

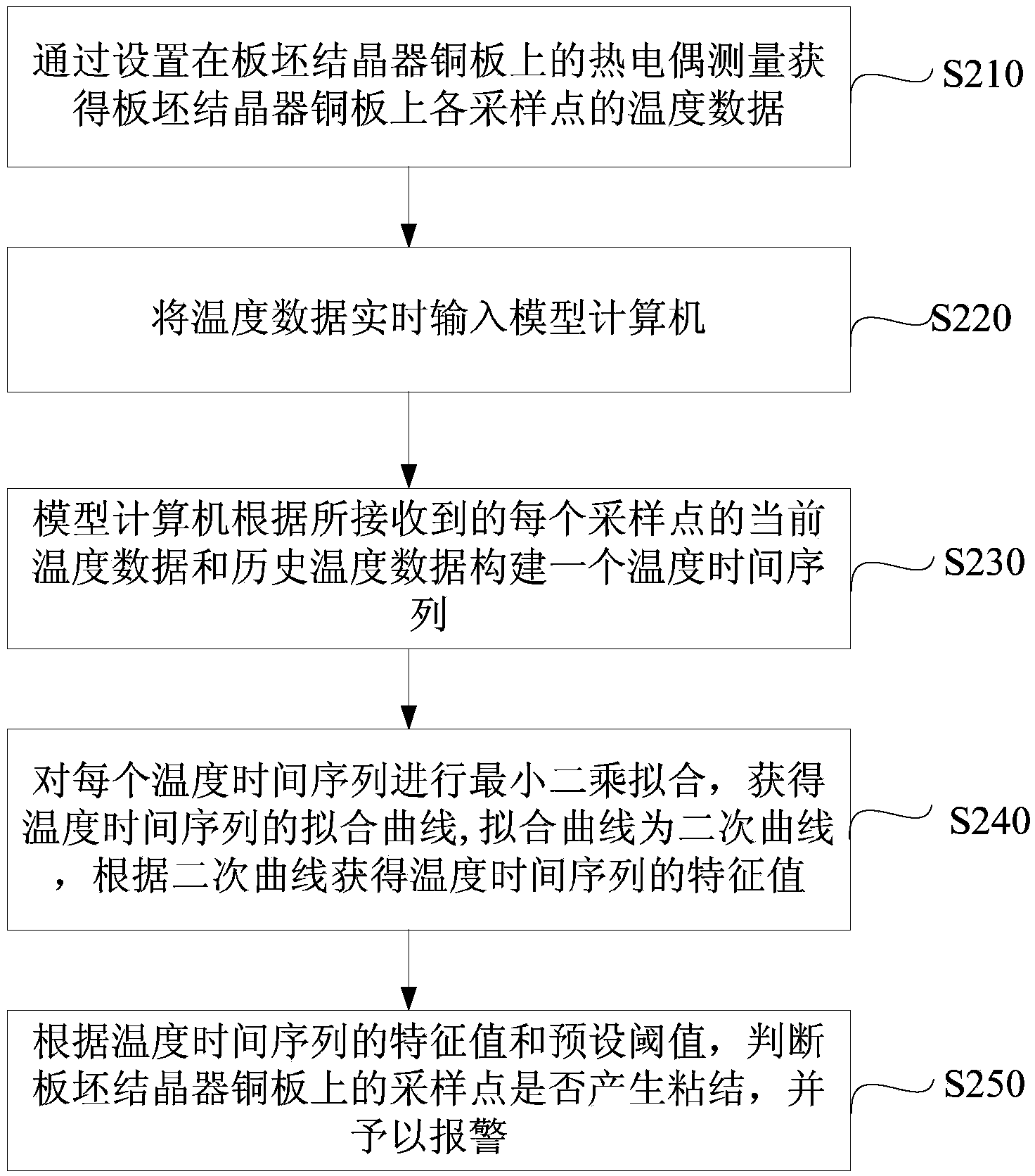

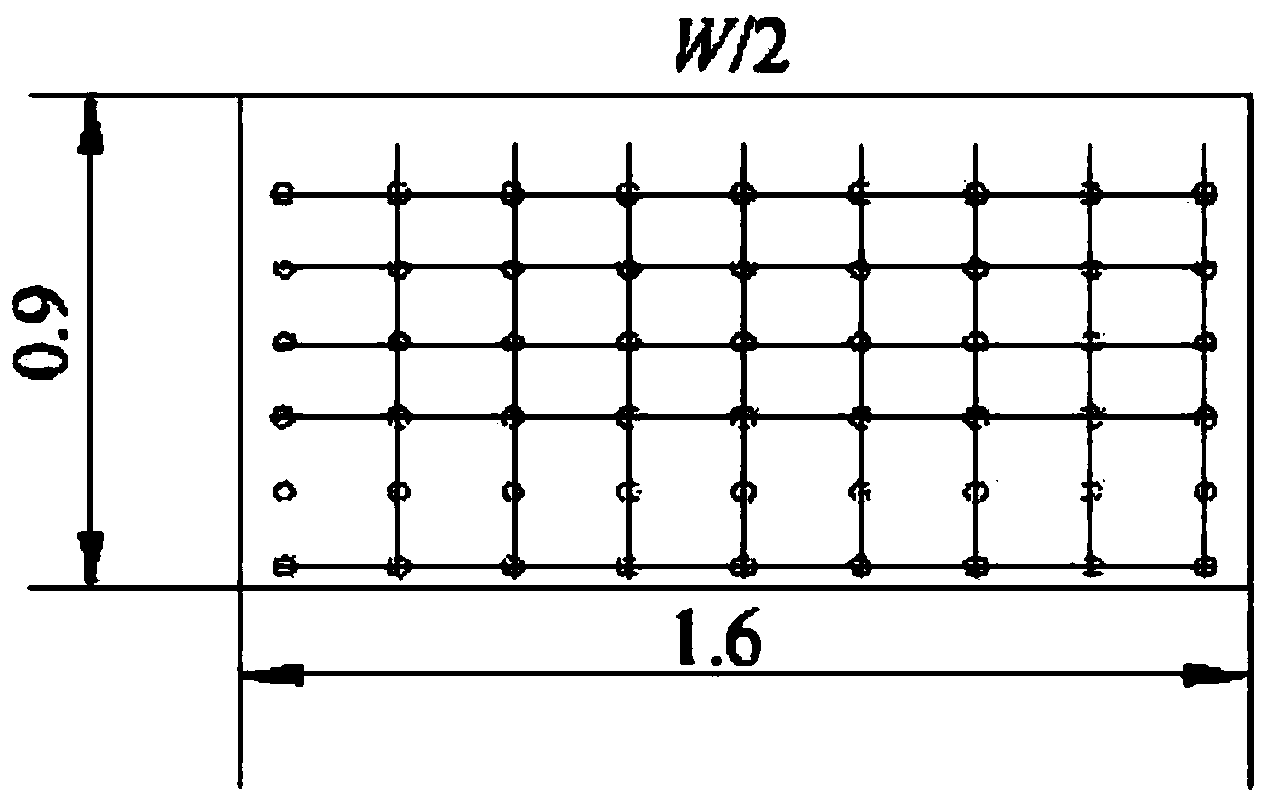

[0056] Known from the foregoing, the slab mold breakout prediction is of great significance in the slab continuous casting production. As the slab pulling speed is getting higher and higher, the breakout forecast requires the alarm time to be earlier and more timely, so as to allow sufficient reaction time. Breakout forecasting should also consider the timeliness of the alarm time while focusing on the accuracy. The present invention proposes a new breakout prediction method, which uses the least squares method to fit the collected temperature data, calculates the size of the characteristic value, and judges the difference between the slab and the Whether there is bonding between the copper plates. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com