3-teeth double-rotor flowmeter

A dual-rotor, flowmeter technology, applied in the direction of volume/mass flow, volume indication and recording equipment generated by mechanical effects, can solve the problems of non-continuous measurement, inaccurate measurement accuracy, and limited service life of flowmeters, and achieve good results. The effect of continuous sealing lines, high metering accuracy, and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

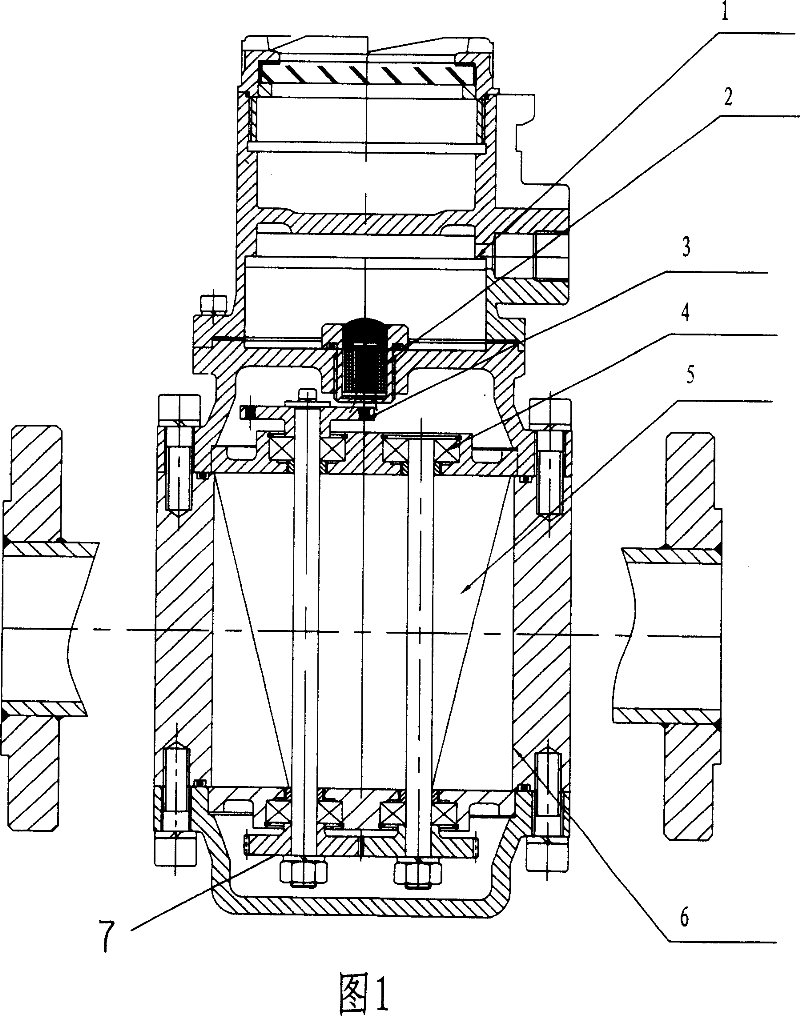

[0011] The invention is given by the following examples and accompanying drawings. See attached drawings 1-2.

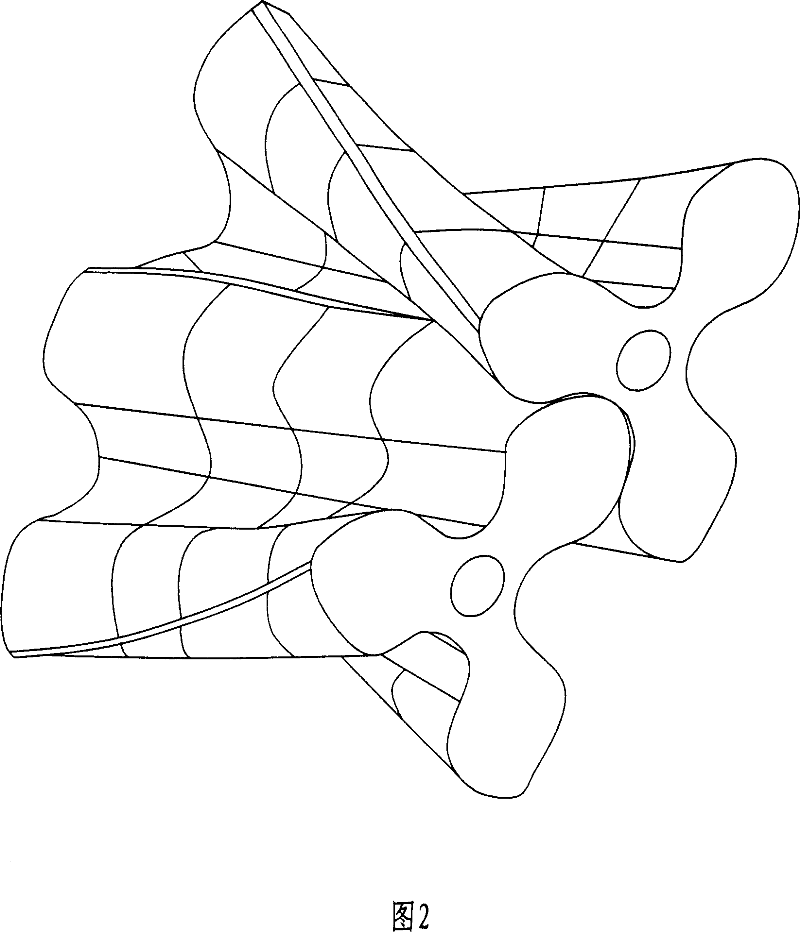

[0012] A three-tooth gas double-rotor flowmeter, the rear part of the metering cavity 5 is connected with a signal-sending magnet 3, a sensor 2, and an electronic counter 1. There is a rotor in the metering cavity 5, which is characterized in that the rotor is a three-tooth helical rotor 4, and the rotor It is arc cycloid type, and the tooth shape is composed of four curves, which are composed of long cycloid, short cycloid, involute and arc line in sequence from the tooth tip. The metering chamber 5 is connected to the double rotors through the bearing 6 and the driving gear 7, and the rotors are fixedly connected to the rotor shaft; the front ends of the double rotor shafts are respectively fixedly connected to the driving gear 7, and the two driving gears mesh; the rear end of one rotor is fixedly connected to the sending magnet 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com