Blasting engineering air spacing device

A technology of air separation and blasting engineering, applied in blasting and other directions, can solve the problems of high unit price, cumbersome operation, increase blasting cost, etc., and achieve the effect of convenient operation, low cost, and improved abutment strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to facilitate the understanding and implementation of the present invention, the preferred embodiments of the present invention are selected for further description in conjunction with the accompanying drawings.

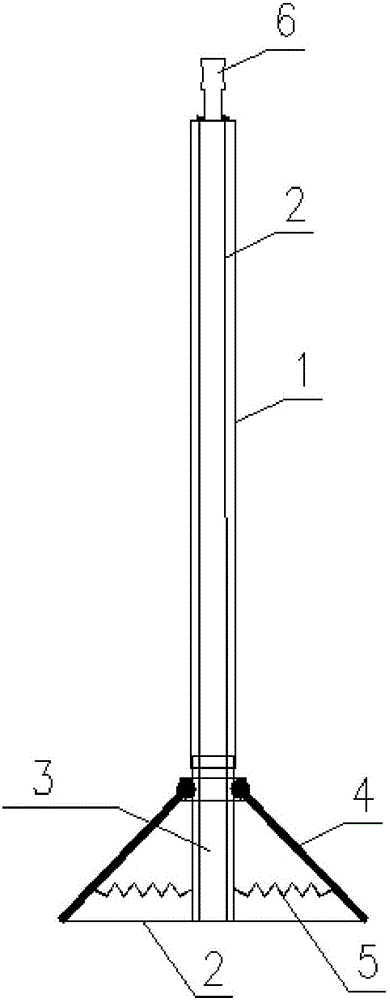

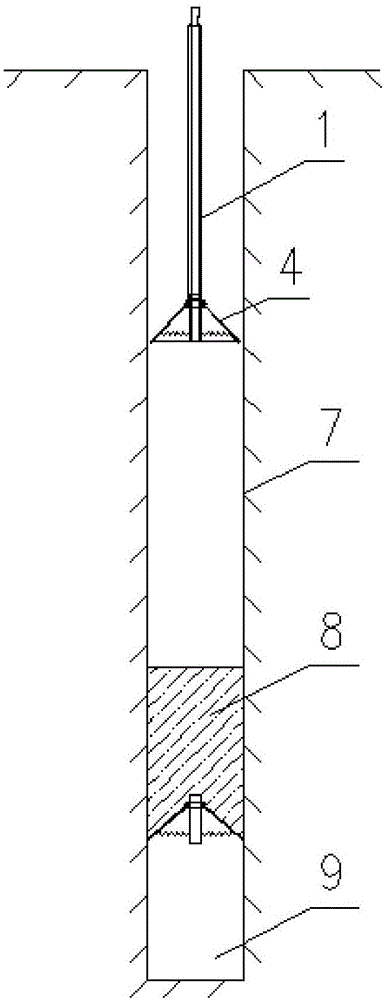

[0015] like figure 1 As shown, the present invention includes an operating rod 1 and a support frame; the operating rod 1 has an operating rod connecting hole arranged along its axial direction; the supporting frame includes a fixed rod 3, and the fixed rod 3 has a fixed rod connecting hole arranged along its axial direction, The top of the outer wall of the fixed rod 3 is provided with at least two struts 4 that are hingedly connected, and the adjacent two struts 4 are connected by a flexible connector, and the outer wall of each strut 4 is connected with the outer wall of the fixed rod 3 by a spring 5. The lower end of each support rod 4 is fixedly connected with a connecting rope 2; the top of the fixed rod 3 is threadedly connected with the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com