Conical cycloid wheel planet transmission means

A technology of planetary transmission and conical pendulum, applied in the direction of gear transmission, transmission, belt/chain/gear, etc., can solve the problems of low carrying capacity, difficult manufacturing, affecting transmission accuracy, etc., and achieve high carrying capacity and high processing Accuracy and efficiency, the effect of high contact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

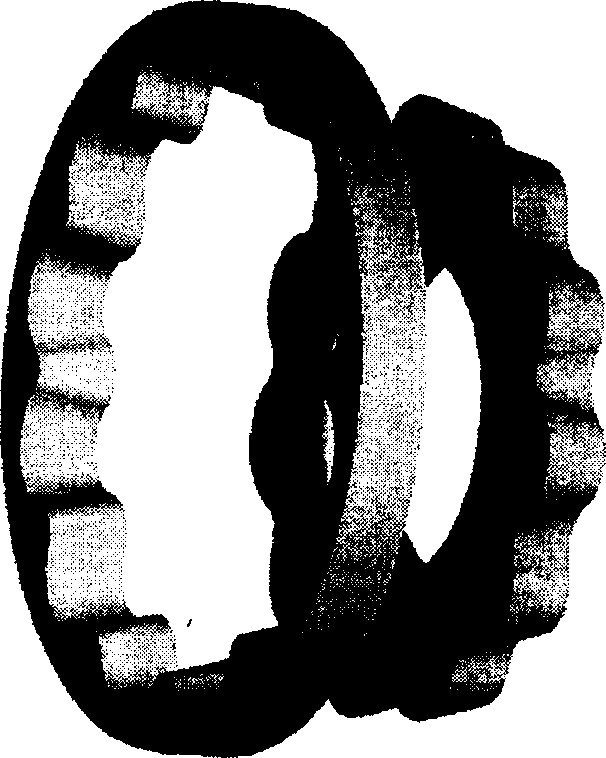

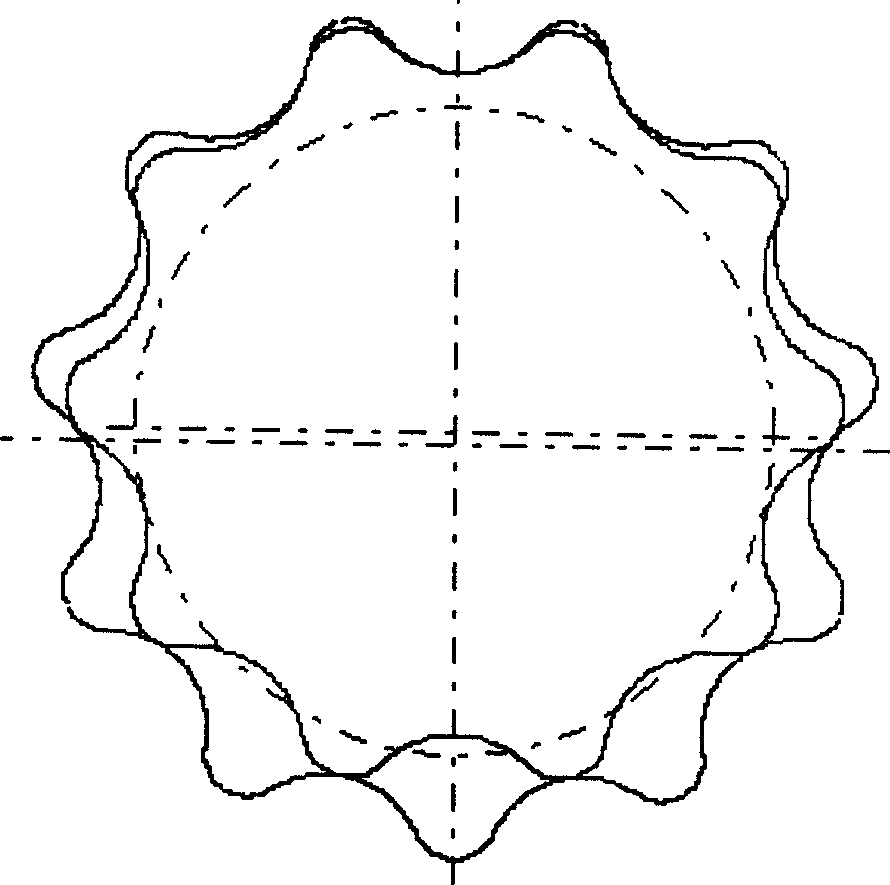

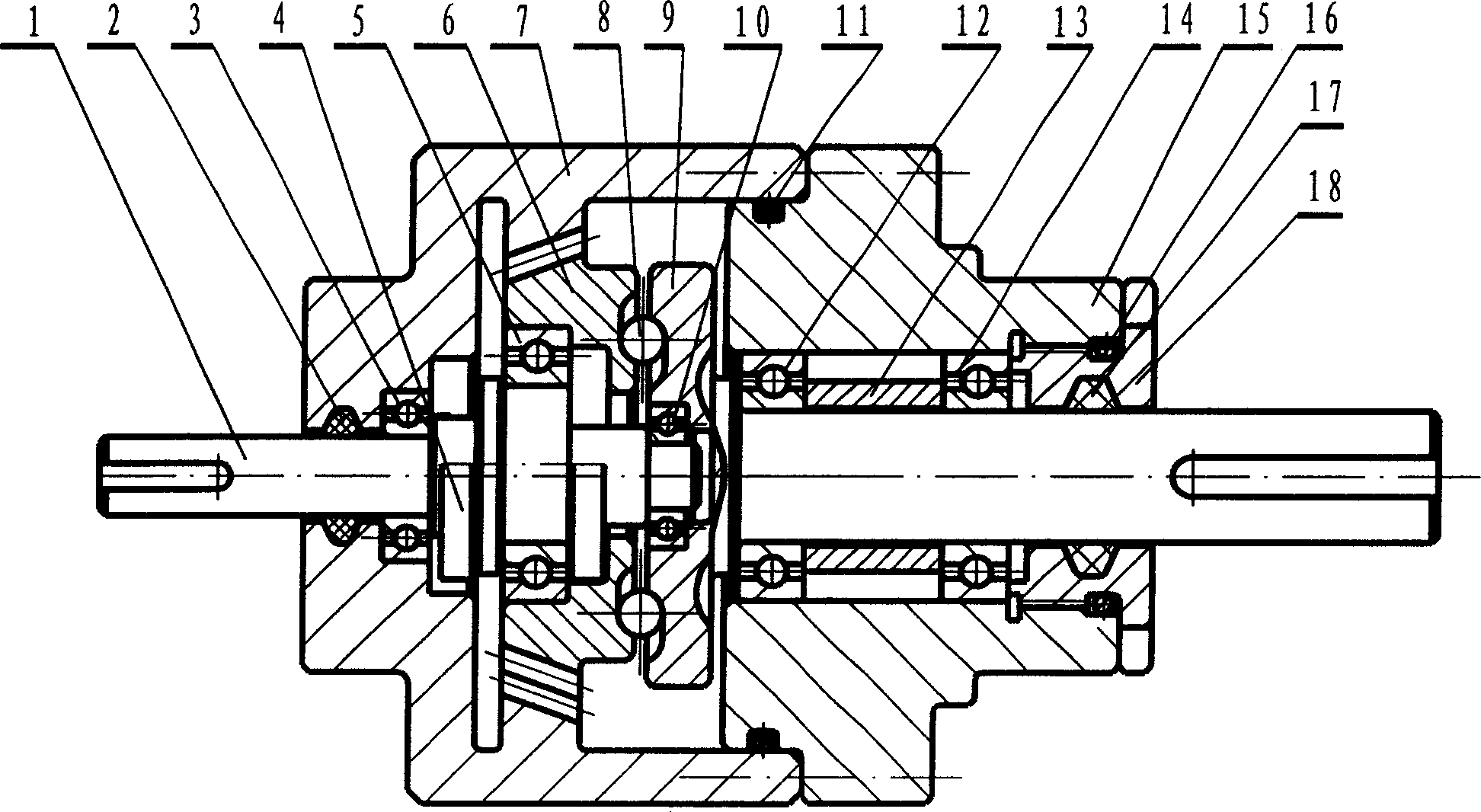

[0019] exist figure 1 Among them, the conical internal gear with the same cone angle and the conical cycloid planetary gear form a conical cycloid planetary meshing pair; the tooth profile curve of the conical internal gear includes the working arc segment and the transition curve of the dedendum, and the conical The working arc section of any radial section of the internal gear is a concentric arc; the tooth profile curve of the conical cycloid planetary gear is the equidistant line of the short cycloid, and the radial section of any radial section of the conical cycloid planetary The tooth profile curves are mutually equidistant lines.

[0020] exist figure 2 Among them, the meshing transmission of any radial section of the conical cycloid planetary meshing pair is a precise meshing cycloid planetary transmission; the working arc radius of the conical internal gear changes continuously along the axial direction, while the conical cycloid The tooth profile curve of the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com