Low temperature superconducting magnet joint lap joint soldering technology

A low-temperature superconducting and soldering technology, applied in superconducting magnets/coils, magnetic objects, connecting contact materials, etc., can solve the problems of increasing joint resistance, affecting the contact effect, reducing strength, etc., to achieve low contact resistance, The effect of high reliability and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

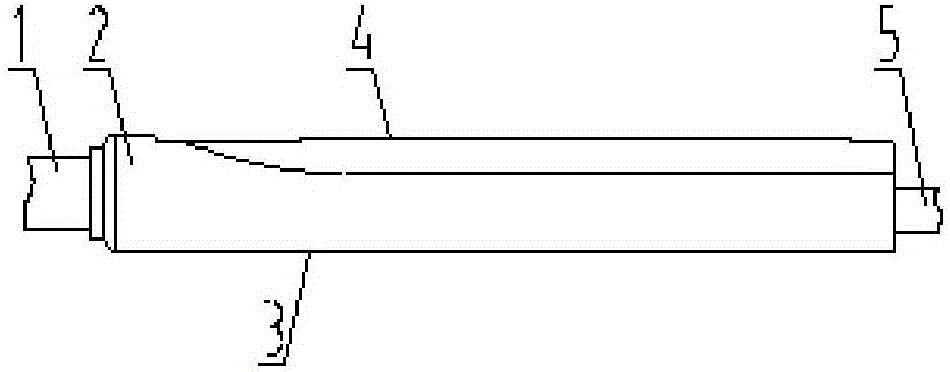

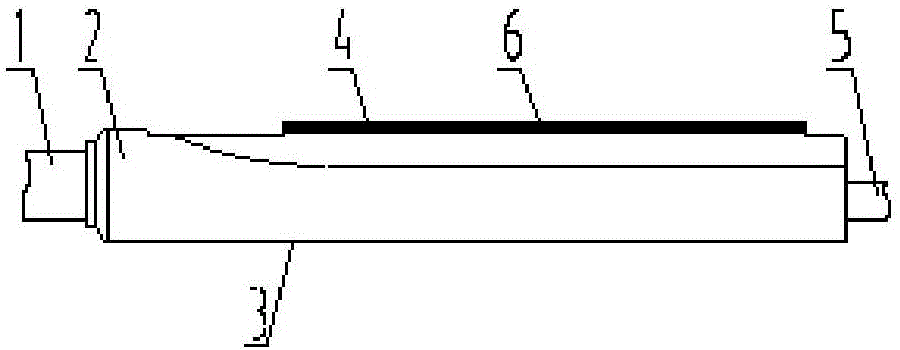

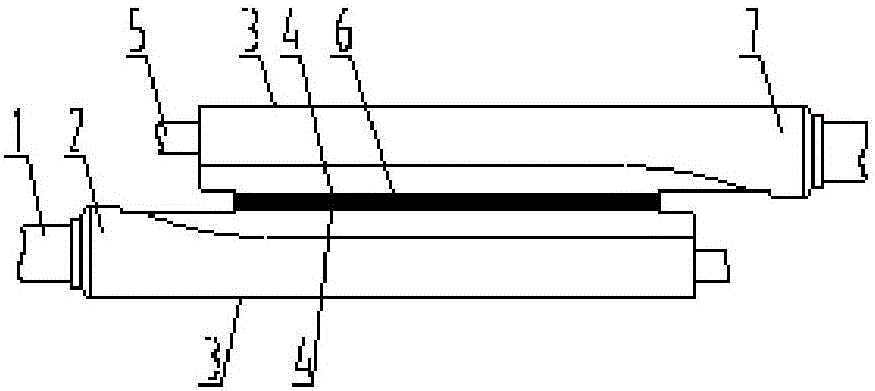

[0023] A low-temperature superconducting magnet joint lap soldering technology, which is characterized in that it includes two steps of tin-coating on the copper surface of the superconducting conductor 1 and double joint lap soldering. The superconducting joint of the superconducting conductor 1 is connected with Liquid helium tube 5, of which:

[0024] The specific steps of tin hanging on the copper surface of the single joint are as follows:

[0025] (1) The copper surface 4 of the single joint box body Ⅰ2 and joint box body Ⅱ7 is placed horizontally upwards, the stainless steel surface 3 of the joint is covered with a cast aluminum heating plate, and the temperature monitoring points are arranged on both sides of the joint copper surface 4;

[0026] (2) The joint is heated at a heating rate of 5°C / min. When the temperature of the copper surface 4 of the joint reaches 120°C, the heating equipment is adjusted to the heat preservation state. At this time, the joint copper surface 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com