Low temperature solid-oxide fuel battery three-in-one component MEA and preparation thereof

A solid oxide and fuel cell technology, applied in the direction of solid electrolyte fuel cells, fuel cell grouping, fuel cell components, etc., can solve the problem of large interface resistance, reduce interface resistance, improve battery efficiency, and improve contact strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

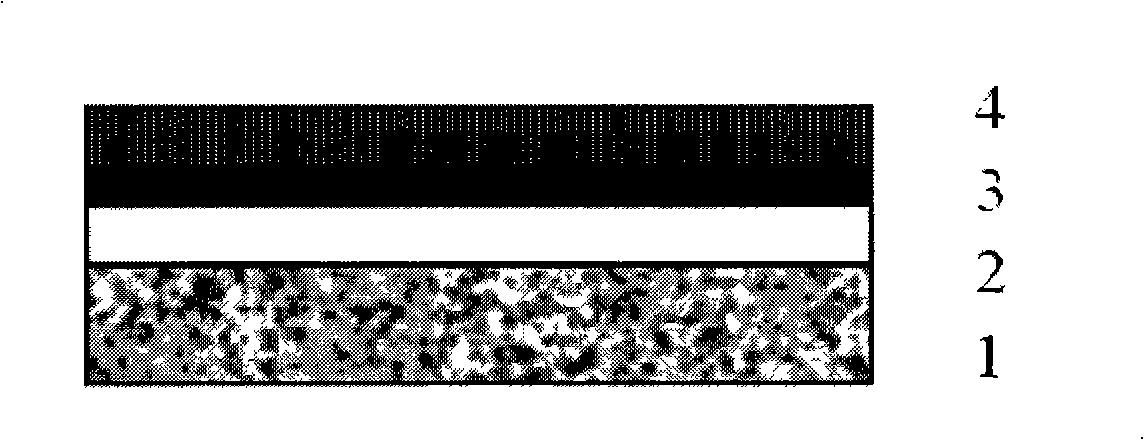

[0025] Flat Low Temperature Solid Oxide Fuel Cell with LSM as Transition Layer

[0026] Such as figure 1 Shown is a schematic diagram of the structure of an anode-supported low-temperature solid oxide fuel cell with a perovskite-type composite oxide transition layer, including an anode substrate 1, a cerium-based electrolyte diaphragm layer 2, a perovskite-type composite oxide transition layer 3 and Cathode 4. The NiO-GDC / GDC two-in-one was prepared by dry pressing, in which the GDC electrolyte was synthesized by glycine method, and the two-in-one was co-fired at 1420°C for 4 hours to obtain the anode / electrolyte assembly. Prepare an LSM transition layer with a thickness of 500 nm on the side of the GDC electrolyte by casting method, dry it in the air, and bake it at a temperature lower than 120 °C for 2 hours to obtain a porous LSM transition layer.

[0027] The BSCF-GDC composite cathode was prepared by coating method, in which the BSCF content was 70%, and baked at 950°C ...

Embodiment 2

[0030] Flat Low Temperature Solid Oxide Fuel Cell Using LSGM as Transition Layer

[0031] The NiO-SDC / SDC two-in-one was prepared by casting method, in which the SDC electrolyte was synthesized by citric acid method, and the two-in-one was co-fired at 1450 °C for 4 hours to obtain the anode / electrolyte assembly. Prepare a LSGM transition layer with a thickness of 0.75 microns on the side of the SDC electrolyte by casting method, dry it in the air, and bake it at a temperature lower than 200°C for 2 hours to obtain a porous LSGM transition layer.

[0032] The BSCF-SDC composite cathode was prepared by screen printing method, in which the BSCF content was 70%, and baked at 950°C for 2 hours.

[0033] Using hydrogen as fuel gas and oxygen as oxidant, test battery performance at 500-600°C. The maximum power density reaches 0.91W cm at 600°C -2 , which is 58.5% higher than that of the battery with the same conditions but without a transition layer.

Embodiment 3

[0035] Flat Low Temperature Solid Oxide Fuel Cell Using LSCF as Transition Layer

[0036] The flat-plate NiO-GDC / GDC two-in-one was prepared by rolling film method and baked at 1500 ° C. The LSCF transition layer with a thickness of 500 nm was prepared on the electrolyte side by spraying method. The GDC and LSCF materials were prepared by citric acid method. Baking the electrolyte at a temperature of 200° C. for 1 hour to obtain a dense anode / electrolyte assembly with both the electrolyte and the transition layer.

[0037] The BSCF-GDC composite cathode was prepared by screen printing method, in which the BSCF content was 70%, and it was baked at 1000℃ for 2 hours.

[0038] Using hydrogen as fuel gas and air as oxidant, test battery performance at 500-600°C. The maximum power density reaches 0.3W·cm at 500℃ -2 , which is 31.2% higher than that of the battery with the same conditions but without a transition layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com