Clamping device for voltage-withstanding testing of capacitor core group

A technology of withstand voltage test and clamping device, applied in the direction of measuring device casing, etc., can solve the problems of reducing the reliability of capacitors, poor contact, damage to capacitor core groups, etc., saving charging and discharging time, enhancing contact strength, and improving labor efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The content of the present invention will be described below in conjunction with specific embodiments.

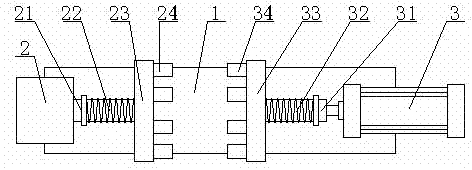

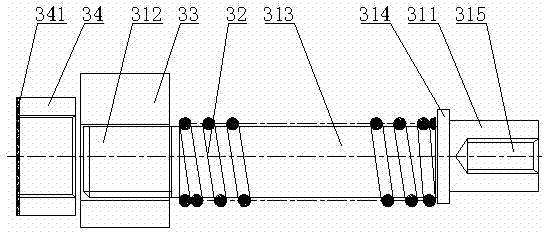

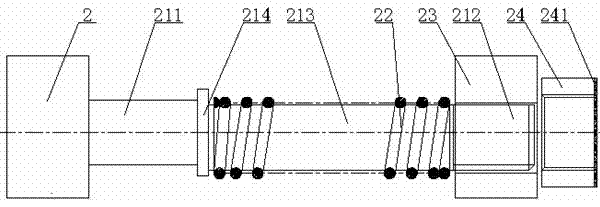

[0018] like Figure 1-5 As shown in FIG. 1 , it is a structural schematic diagram of the clamping device for withstand voltage testing of capacitor core packs according to the present invention. The clamping device for withstand voltage test of the capacitor core group according to the present invention includes: a base 1, a fixed part, and a movable part arranged opposite to the fixed part; it is characterized in that: the fixed part includes an end seat 2, a connecting rod 21. Spring one 22, installation seat one 23, fixed chute one 24, the end seat 2 is fixed on the base 1, the connecting rod one 21 connects the end seat 2 and the installation seat one 23 , the spring one 22 is arranged between the end seat 2 and the installation seat one 23, and the fixed chute one 24 is arranged on the said installation seat one 23 and there are a plurality of them. Generally, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Elastic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com