Modular apparatus for realisation of easily removable horizontal or vertical tiling

A tile and pavement technology, applied to floors, coverings/linings, buildings, etc., can solve problems such as inability to remove paving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

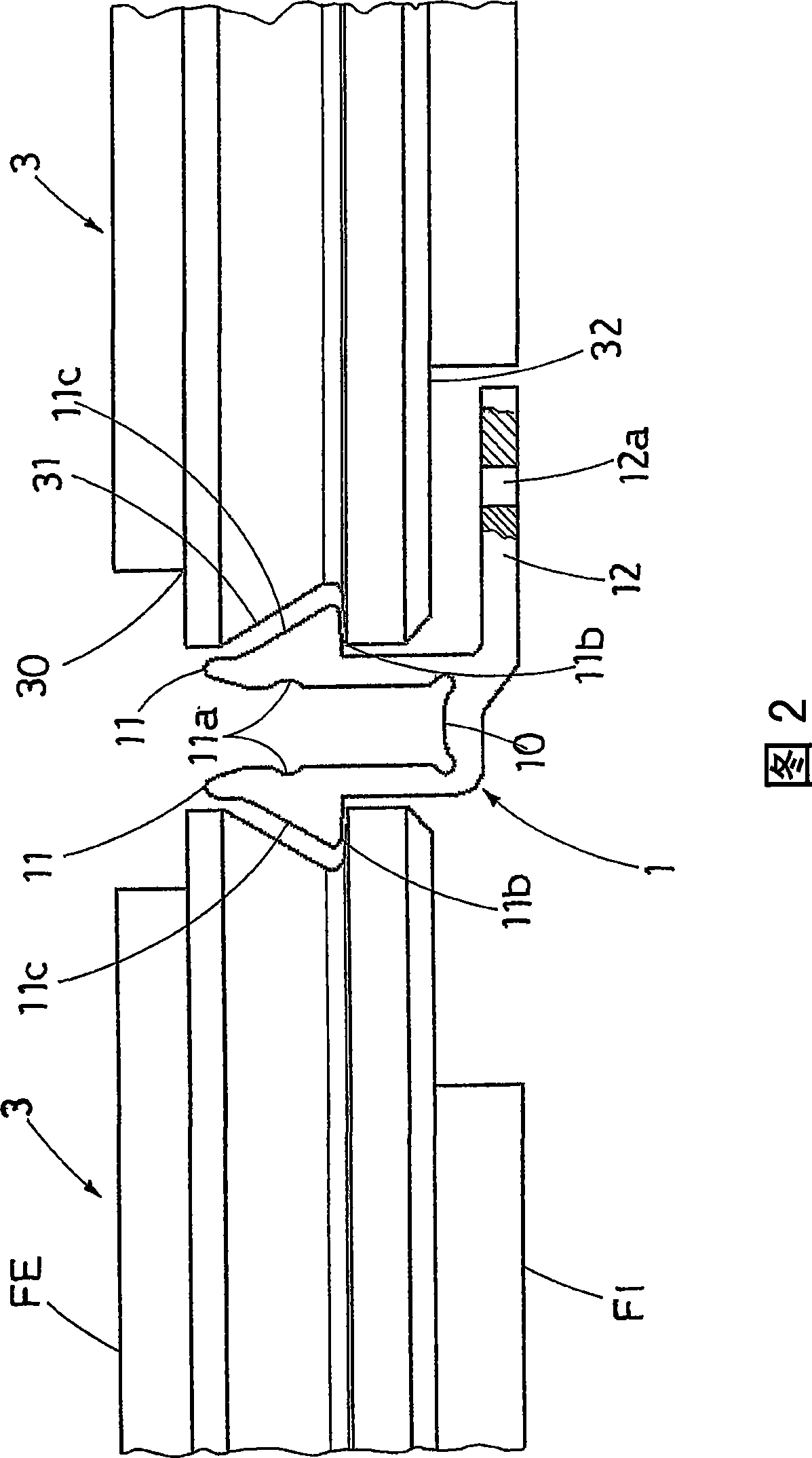

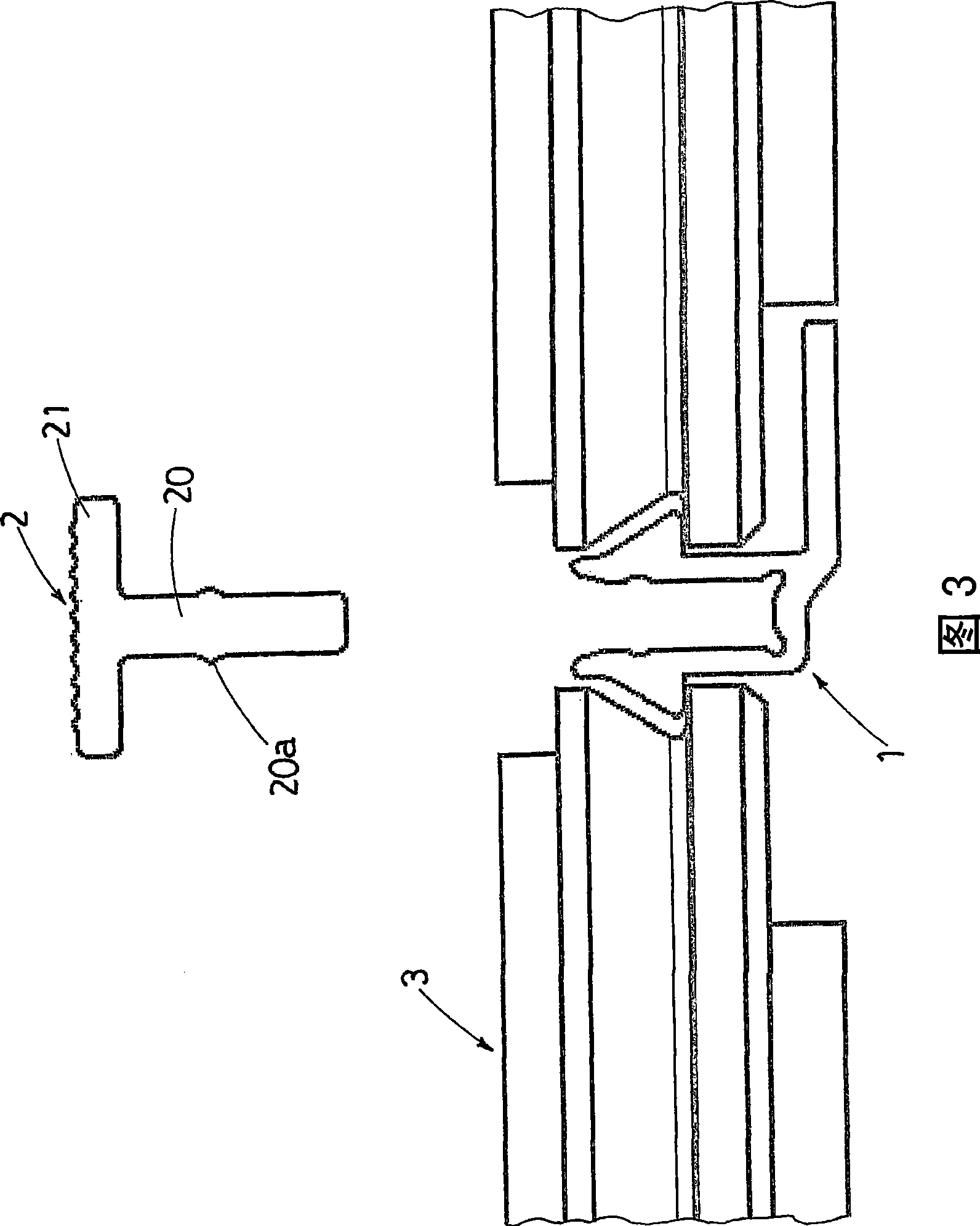

[0023] Referring to the drawings, the modular arrangement of the present invention comprises three different assemblies (or modules) for connection, the number and pattern of which are determined by the given paving material to be obtained.

[0024] The first module of the device consists of the aforementioned rectilinear part 1 with a substantially U-shaped transverse section, provided with a bottom wall 10 and two elastically bifurcated sides in symmetrically opposite positions. 11.

[0025] In particular, each side 11 is internally provided with a small longitudinal groove 11a at approximately three-quarters of its height; tooth 11b.

[0026] As shown in FIG. 2 , the first part 1 is integrally provided with a transverse protruding strip 12 at a position parallel to the back of the bottom wall 10 .

[0027] Another module of the device of the invention consists of a second part 2 having a substantially T-shaped cross-section, provided with a first wing 20 capable of fittin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com