Bearing type overrunning clutch structure

An overrunning clutch and bearing technology, applied in clutches, one-way clutches, mechanical equipment, etc., can solve the problems of large gap between cage and wedge, easy inclination of wedge, small radius of curvature of wedge, etc., to ensure full synchronization The effect of increasing the comprehensive curvature and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

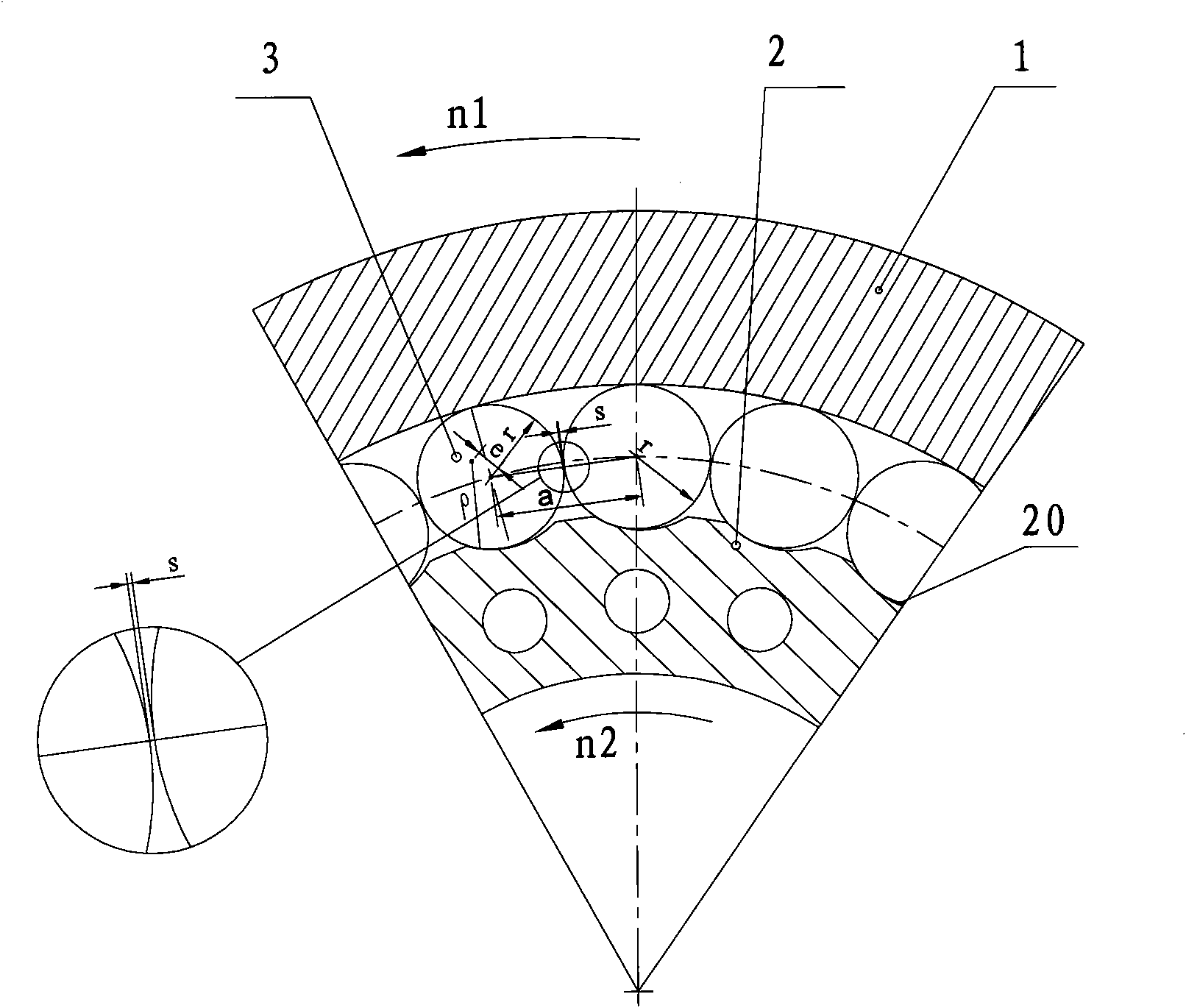

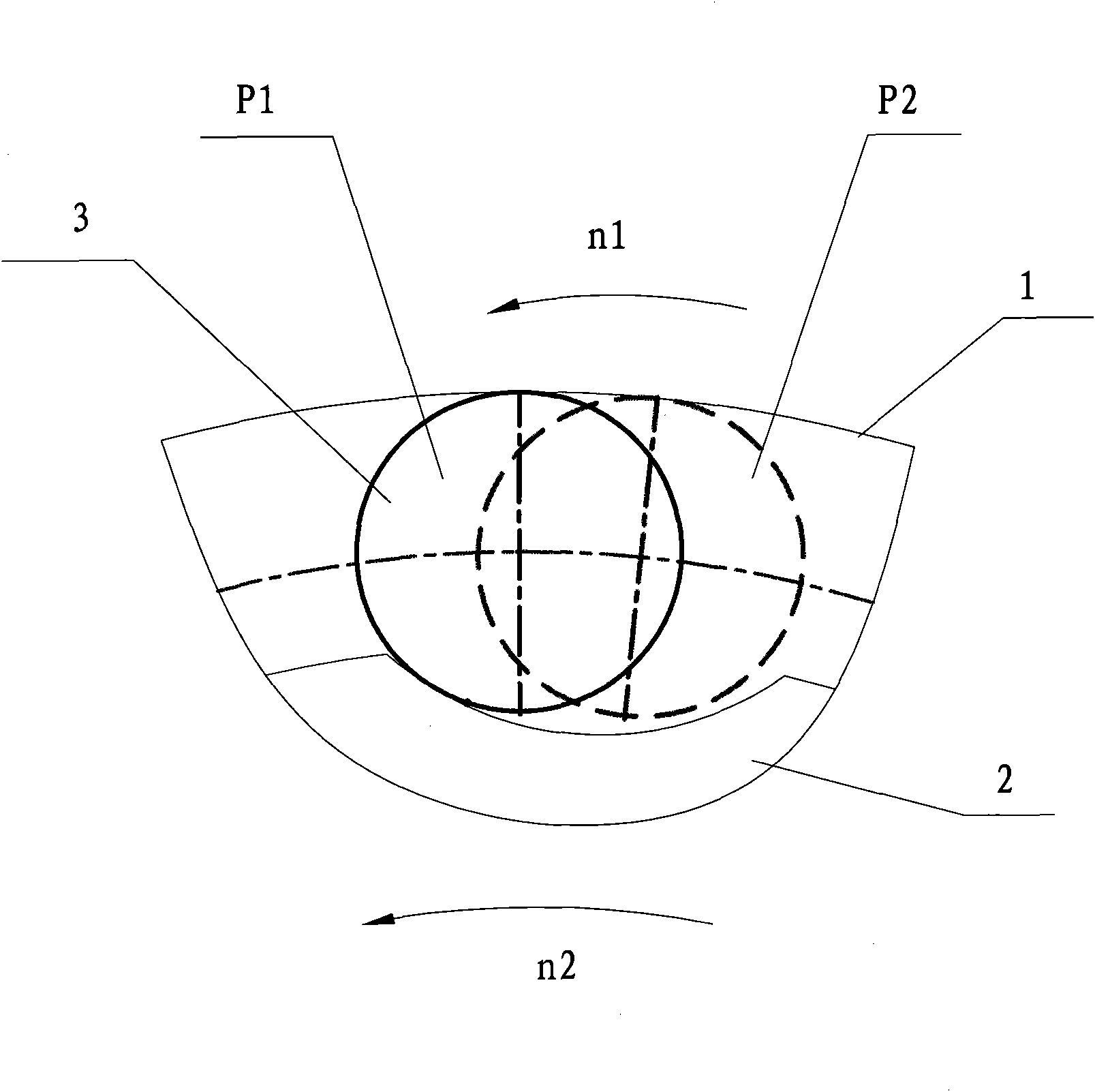

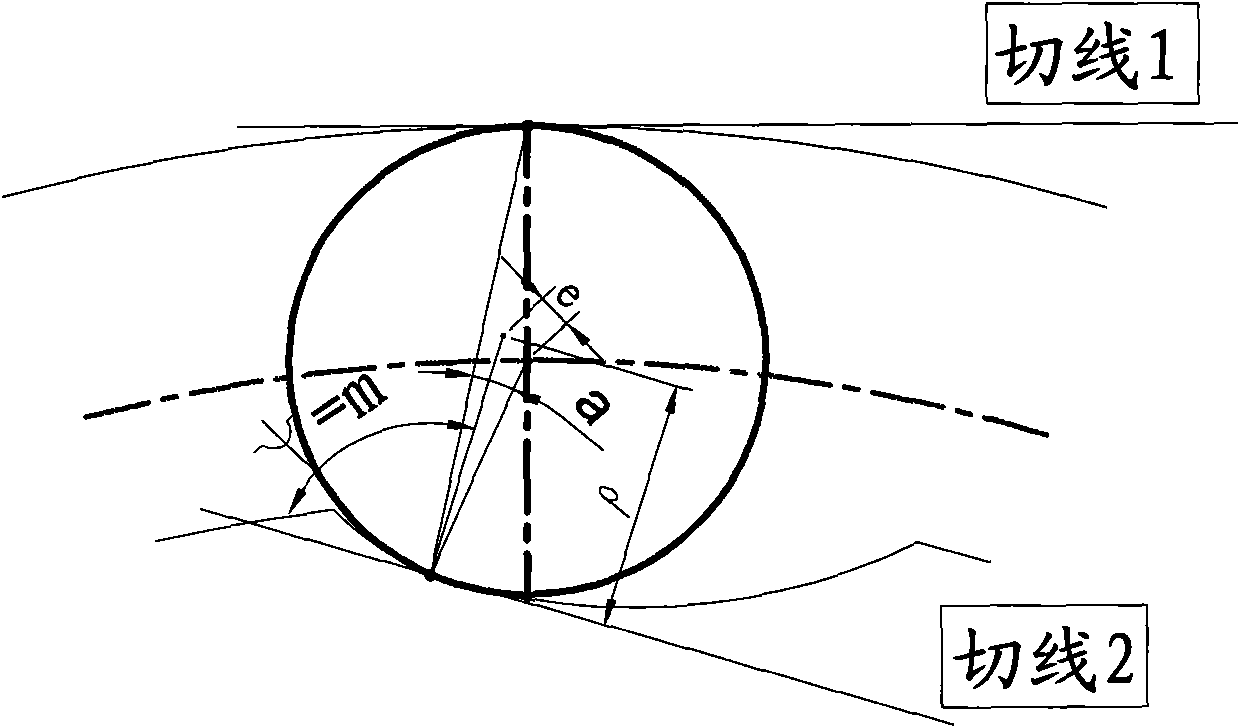

[0027] Example: see figure 2 , the application of a bearing type overrunning clutch in a loader is also called a bearing type loader two-axis assembly overrunning clutch, including an outer ring 1, an inner star wheel 2, and a roller 3, between the outer ring 1 and the inner star wheel 2 There are 24 rollers 3 between them, and 24 concave curved surface grooves are arranged on the outer cylindrical surface of the inner star wheel 2, one concave curved surface groove corresponds to one roller 3. Such as image 3 , the concave surface in the concave surface groove is composed of logarithmic helix, since the angle ψ (ie the pitch angle) between the tangent at any point on the logarithmic helix and the polar radius ρ of this point is a constant m, From instant meshing to full transmission of torque, the meshing angle α between the roller and the inner raceway remains unchanged, so the force acting on each roller is equal. Such as figure 2 As shown in , when the inner star whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com