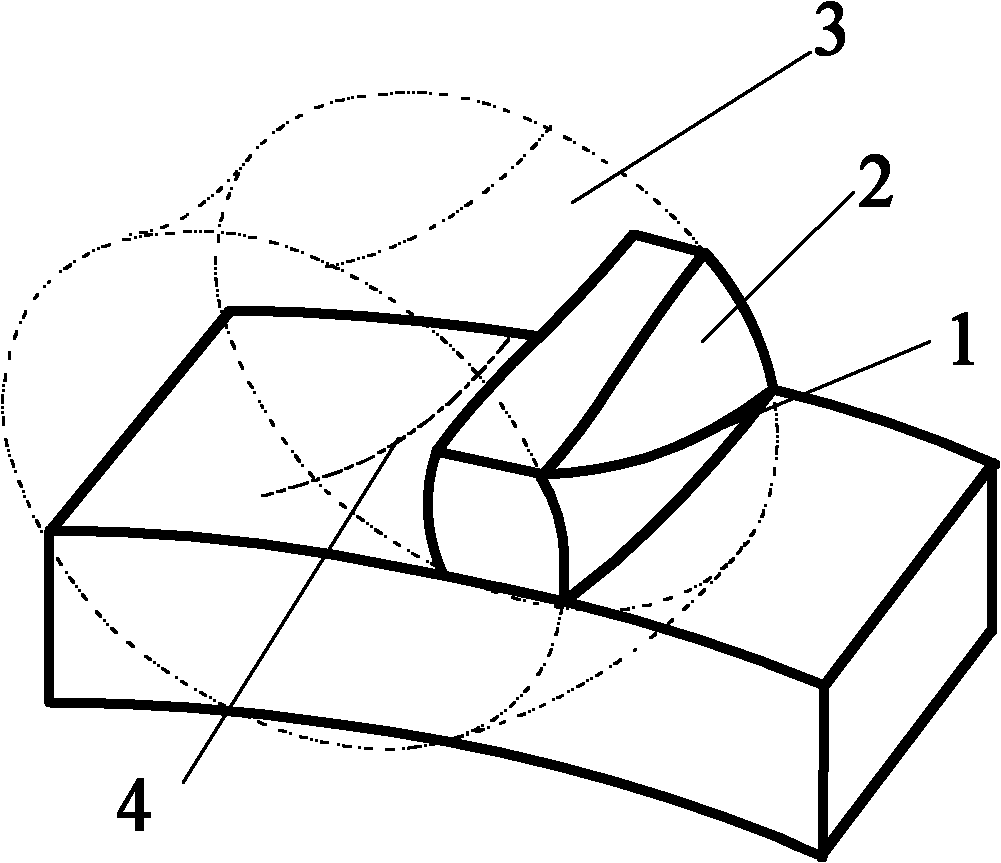

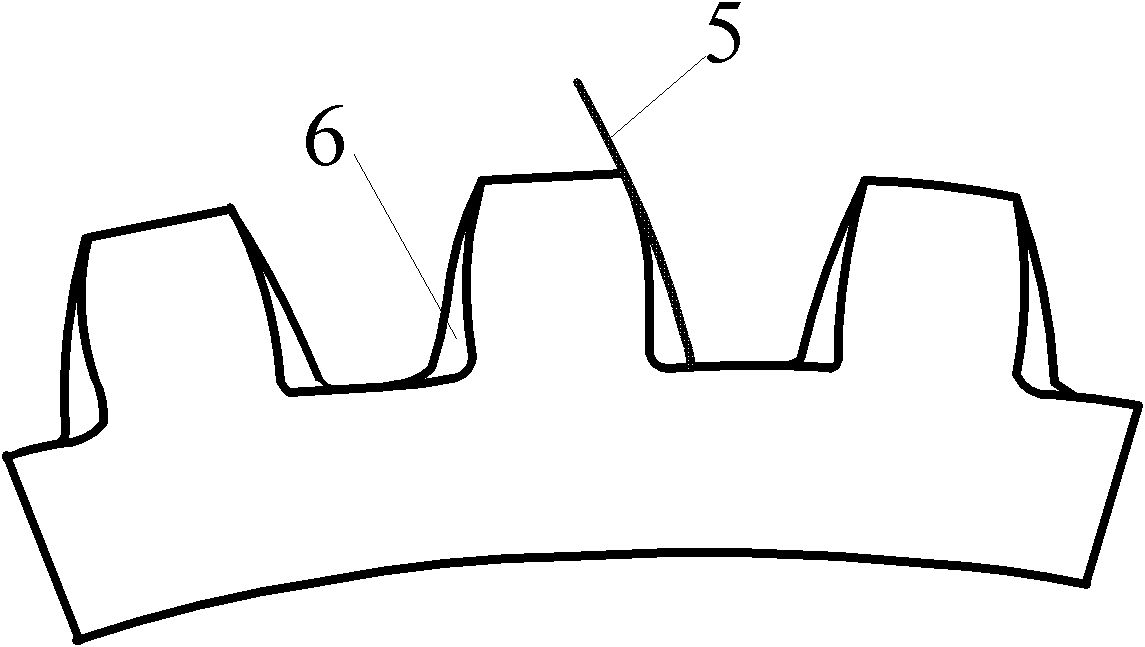

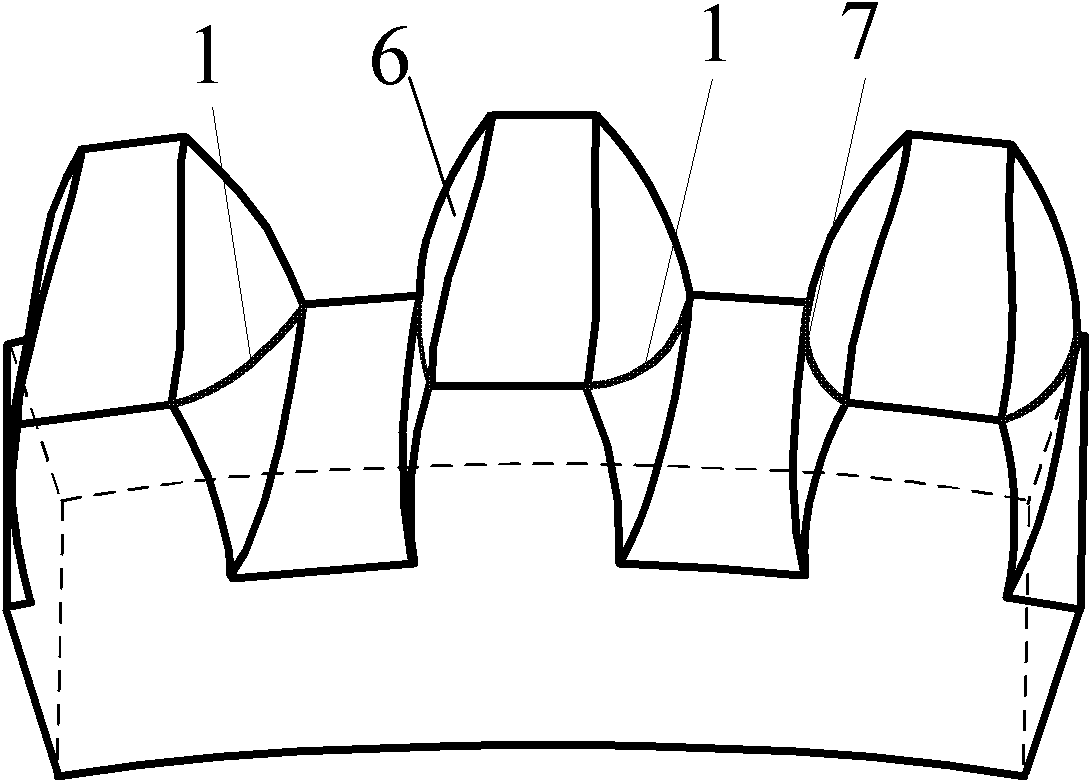

Involute gear transmission device based on line and plane conjugation

A technology of involute gears and transmissions, which is applied in the direction of gear transmissions, transmissions, hoisting devices, etc. It can solve the problems that the arc gear's load-bearing capacity and transmission accuracy cannot be used in the field of precision transmission, and achieve low noise and high load bearing capacity. The effect of high capacity and high contact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 The said engagement tube equation:

[0046]

[0047] The contact line equation of the involute external gear tooth profile:

[0048]

[0049] The conjugate contact line equation of the tooth profile curve along the principal normal vector direction (the contact line equation on the tooth surface of the internal gear):

[0050]

Embodiment 2

[0053] Embodiment 2 The engagement pipe equation:

[0054]

[0055] The contact line equation of the involute external gear tooth profile:

[0056]

[0057] The conjugate contact line equation of the tooth profile curve along the principal normal vector direction:

[0058]

[0059] The maximum value of the sliding rate in the meshing area of this embodiment is The maximum sliding rate in the meshing zone of the ordinary involute external meshing pair with the same number of teeth, modulus and tooth width is 2.6454.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com