Point contact gear and meshing pair based on conjugate curves and machining tool thereof

A technology of conjugate curve and point contact, which is applied in the direction of gear tooth manufacturing tools, manufacturing tools, metal processing equipment, etc., can solve the problems of low load capacity of tooth surface, wear of tooth surface, large sliding rate of tooth surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

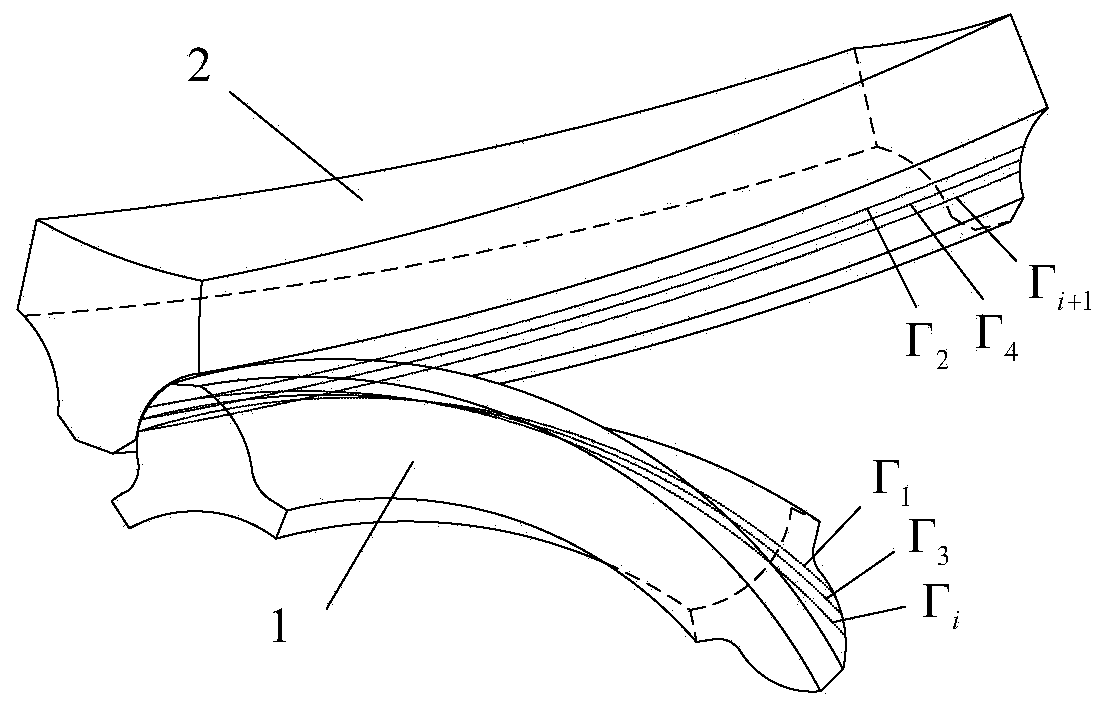

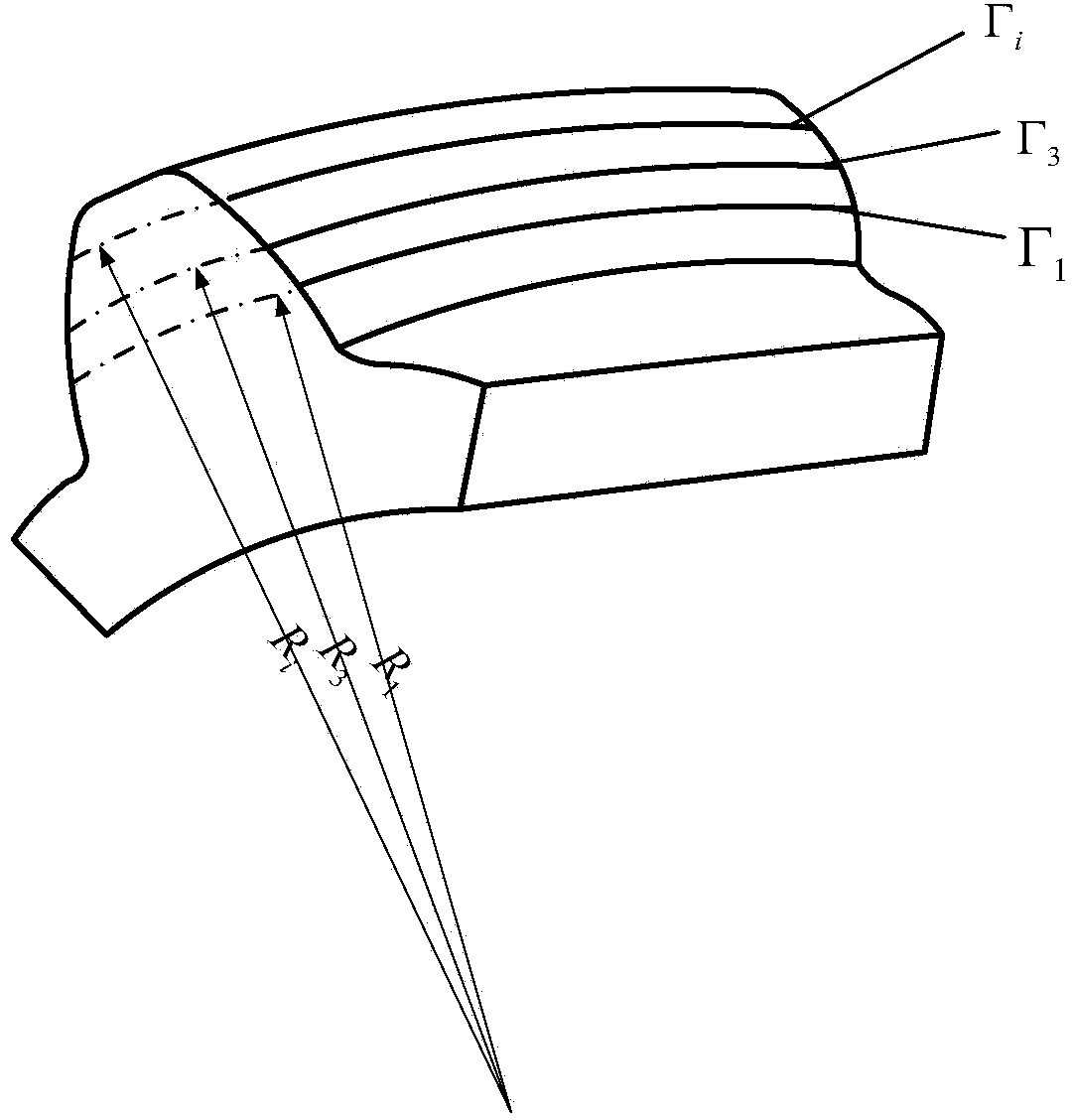

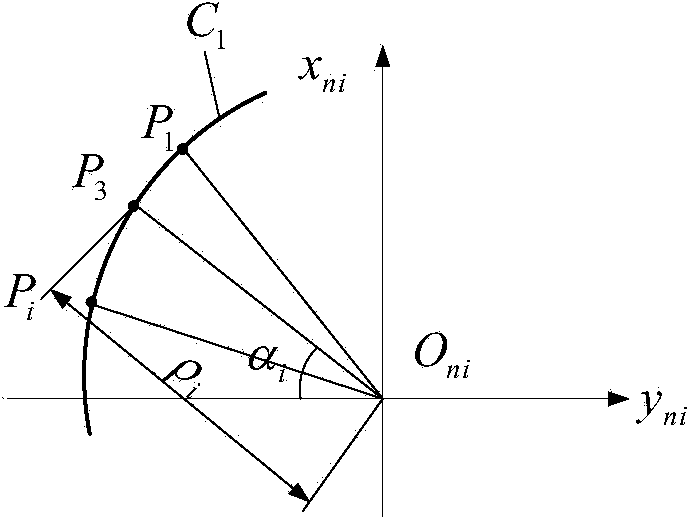

[0092] figure 1 It is a schematic diagram of the single tooth meshing of the point contact gear based on the conjugate curve of the present invention. As shown in the figure, the point contact gear meshing pair based on the conjugate curve, the meshing tooth surface is the meshing tooth surface of the convex tooth gear 1 and the concave tooth gear 2 at one or more points at the same time. The meshing tooth surfaces are the tooth profile curves of convex gear 1 and concave gear 2 along the curve Γ' 1 , Γ' 2 The curved surface formed by the movement, the tooth profile curves of the convex gear 1 and the concave gear 2 are respectively the profile curve C of the convex gear 1 in the common normal plane 1 and concave gear 2 profile curve C 2 . The curve Γ' 1 , Γ' 2 Curve Γ 1 , Γ 2 or curve Γ 3 , Γ 4 or curve Γ i , Γ i+1 (i=1,3,5,...,2n+1) Smooth curves with negative equidistant along the common normal direction at the meshing point. The curve Γ 1 , Γ 2 or curve Γ 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com