Dissimilar metal rolling bonding method with embedded type rib and groove interlocking

A technology of dissimilar metals, rolling and cladding, applied in metal rolling, metal rolling, metal rolling stands, etc., can solve the problems of low bonding strength and increase the probability of diffusion, and achieve simple surface configuration and large bonding area. , The effect of improving the quality of the plate shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

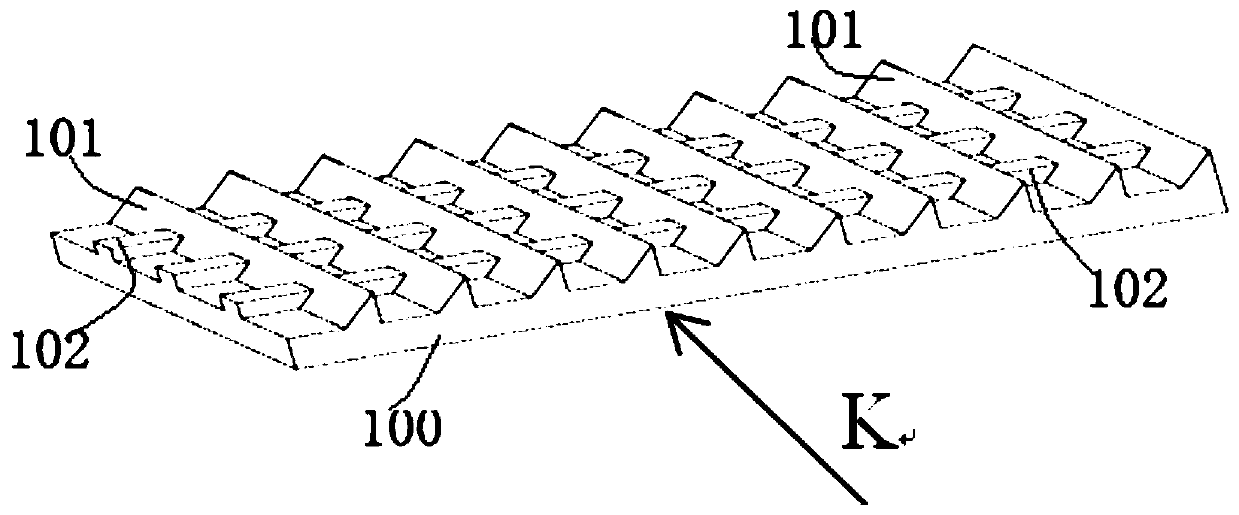

[0061] Such as Figure 1-Figure 9 As shown, the dissimilar metal rolling composite method with embedded rib groove interlocking in this embodiment includes the following steps:

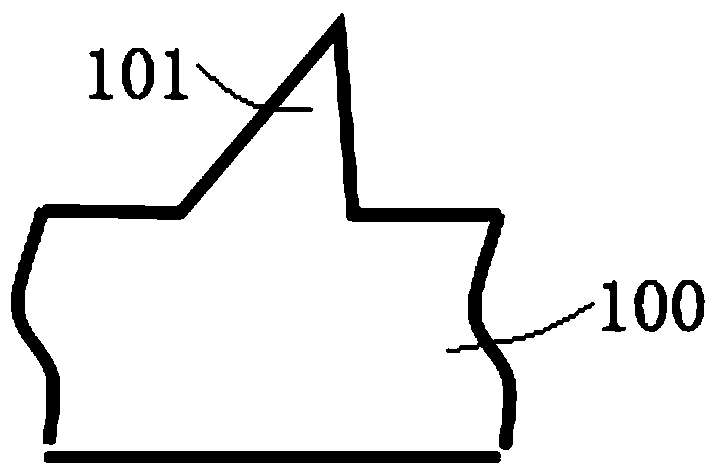

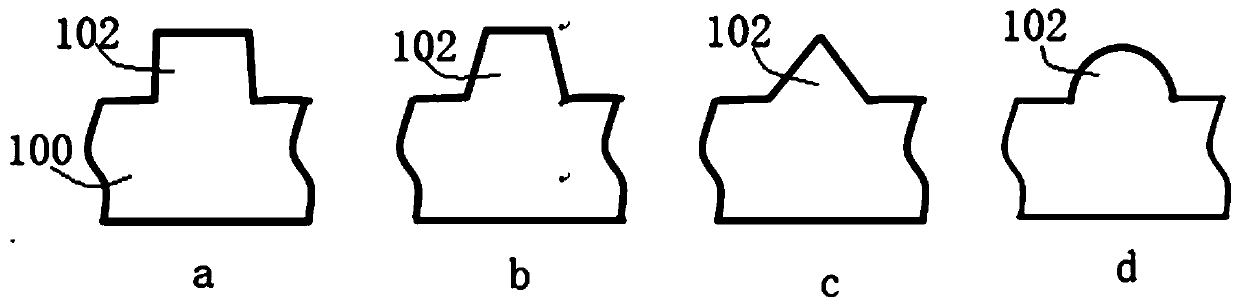

[0062] S1. Forming and rolling with single-sided ribs: select pure Cu plate as a relatively hard component, and the length, width and height of the raw material are 100mm, 100mm and 5mm respectively. A rolling mill is used to roll the Cu plate. Among the upper and lower working rolls of the rolling mill, the patterned roll 200 is used as the upper roll, and the flat roll 300 is used as the lower roll, so as to observe the grooves formed on the rolled piece. The patterned roller 200 has a roll diameter of 118 mm and a roll surface width of 160 mm. The axial cross-sectional shape of the pattern is a zigzag groove, that is, forming transverse grooves 202; 40 grooves are evenly distributed around the roll surface, and the groove depth is 1.5 mm. In the longitudinal direction of the patterned roller 200, ...

Embodiment 2

[0066] The dissimilar metal rolling composite method with embedded rib groove interlocking in this embodiment is basically the same as in Embodiment 1, the difference is that the patterned roller 200 is the upper roller when rolling in step S1 in this embodiment, and the flat roller 300 is the lower roll; and the profile apex angle γ of the formed transverse rib 101 is 30°, and the tooth profile root angle θ of the transverse rib 101 is 90 °; the cross-sectional shape of the formed longitudinal rib 102 is image 3 The trapezoid shown in b; the reduction rate of the asynchronous forming rolling in step S3 is 10%, and the tooth root angle θ of the transverse rib 101 after rolling is further reduced to less than 90°.

Embodiment 3

[0068] The dissimilar metal rolling composite method with embedded rib groove interlocking in this embodiment is basically the same as in Embodiment 2, the difference is that the tooth-shaped apex angle γ of the formed transverse rib 101 in this embodiment is 90°, and the transverse rib The tooth root angle θ of 101 is 80°; the cross-sectional shape of the formed longitudinal rib 102 is image 3 The triangle shown in c; the reduction ratio of the asynchronous forming rolling in step S3 is 50%, and the tooth root angle θ of the transverse rib 101 is further reduced after rolling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com