Method for detecting interface contact strength by double frequency ultrasound

A technology of contact strength and dual-frequency ultrasound, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and measurement devices, which can solve the problem of inability to perform good correspondence and quantitative measurement interfaces. contact strength etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Two kinds of sample materials used in the present invention, one is aluminum alloy, its density and sound velocity are respectively 2708.3 kg / cubic meter and 6030.5 m / s after measurement; kg / m3 and 5916.3 m / s. Among them, for the aluminum alloy samples, the situations with and without Vaseline coupling at the interface were studied respectively. The size of the contact surface of all samples is 30mm×30mm, and the thickness (dimension in the ultrasonic propagation direction) is 5mm.

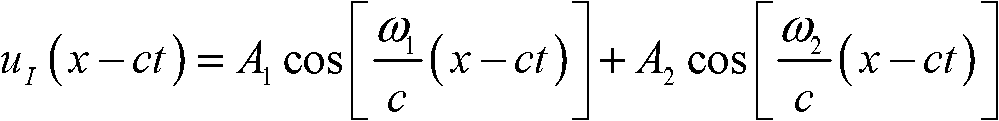

[0049] Such as figure 1 As shown, first use an arbitrary function signal generator (Agilent 33250A, USA) to repeatedly generate an electric pulse containing two frequency sinusoidal components of 500 kilohertz (kHz) and 800 kHz, the pulse repetition frequency is 100 Hz, and the waveform duration is for 80 microseconds. In order to suppress the side lobe in the frequency domain, a Hanning window function was added to the electrical pulse. The electrical signal was passed through a 55 dB ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com