Design method of spiral bevel gear

A technology of spiral bevel gear and design method, which is applied to belts/chains/gears, mechanical equipment, components with teeth, etc., can solve the problem that the parameters are not easy to control, the selection of initial values is harsh, and it is difficult to find the optimal solution, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0045] This embodiment is to design a pair of Gleason spiral bevel gear transmission in the automobile reducer, and the performance specification requirements are shown in Table 1

[0046] Table 1 Spiral bevel gear transmission requirements

[0047] Input powerP / (kw)

10

Small spiral bevel gear speed n 1 / (r / min)

1450

3

Helix angle at midpoint of tooth width β m / (°)

35

Tooth width coefficient φ R

0.3

Life t / (h)

15000

Vibration intensity

slight vibration

Support

with one round cantilever

Allowable reliability of contact strength [R H ]

0.99

Bending strength allowable reliability [R Fj ]

0.99

[0048] (1) Establish a coordinate system

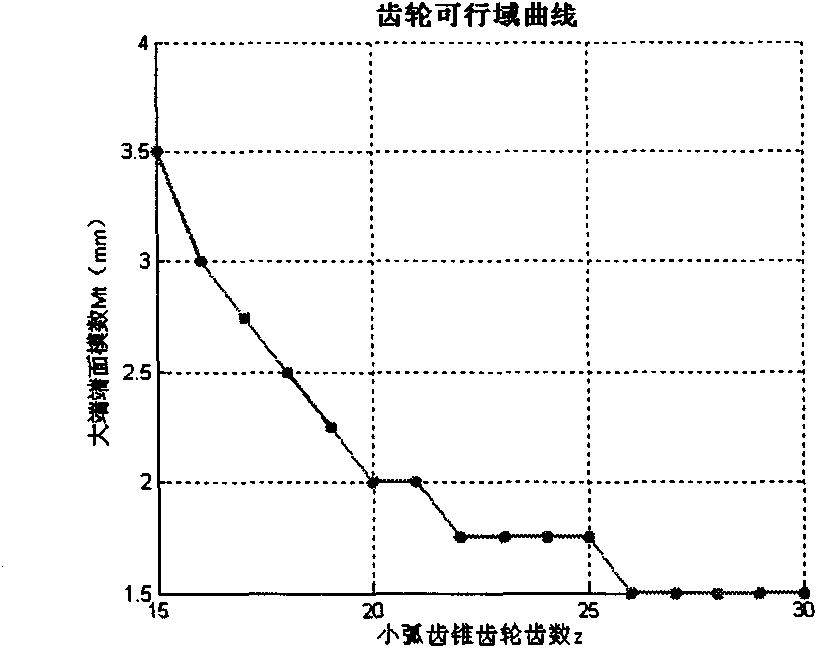

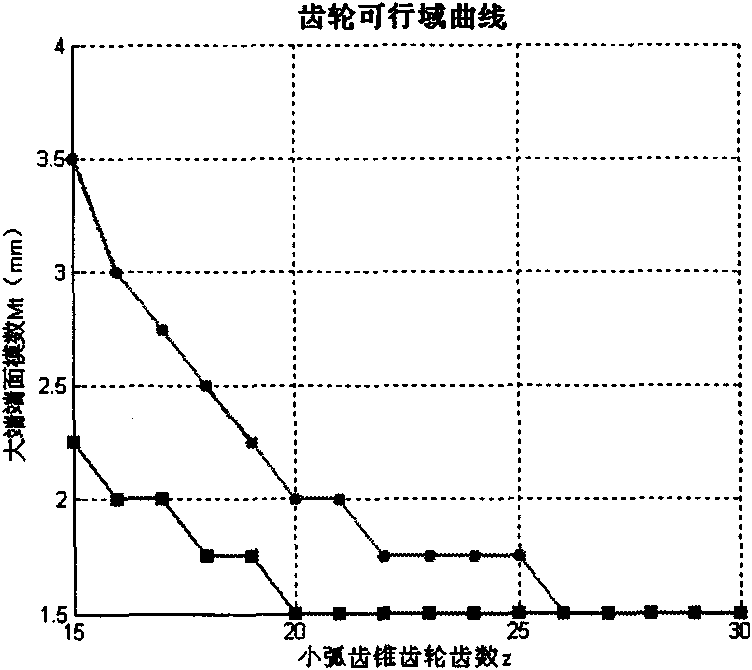

[0049] Take the number of small spiral beve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com