Bevel gear with combined arc tooth profile curves and involute tooth profile curves

A tooth profile curve, involute technology, applied in the direction of elements with teeth, belt/chain/gear, winch, etc., can solve the problem of hindering the bearing capacity and transmission accuracy, low bending strength of the tooth root, difficult to meet the requirements and other problems, to achieve the effect of convenient processing, good running-in, and reducing the contact stress of the tooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

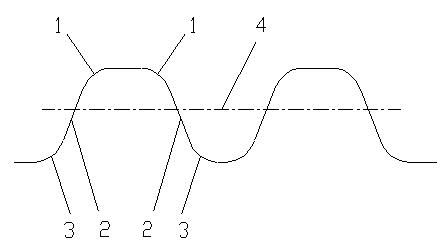

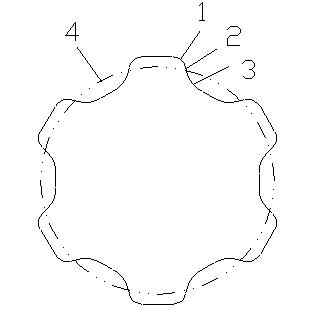

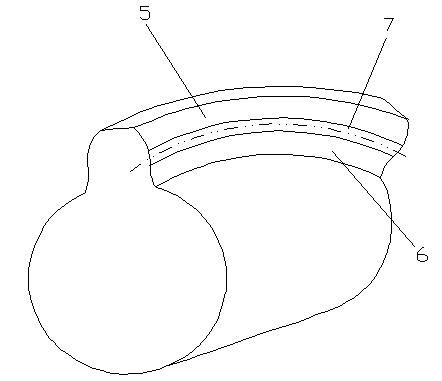

[0021] figure 1 It is a schematic diagram of the normal section tooth profile curve of the helical gear of the present invention; figure 2 It is the overall schematic diagram of the normal section of the helical gear of the present invention; image 3 It is a spatial schematic diagram of the helical gear tooth surface of the present invention.

[0022] Such as figure 1 As shown: the tooth profile curve of the helical gear in this embodiment includes the convex arc line segment 1 of the addendum, the involute line segment 2 and the concave arc line segment 3 of the tooth root connected sequentially from the tooth tip to the tooth root. 1 and dedendum arc 3 are both tangent to involute line segment 2, and the radius of dedendum concave arc line segment 3 is greater than that of addendum convex arc line segment 1. The special tooth profile curve of the helical gear of the present invention makes the helical gear have the separability of the center distance of the involute gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com