Integrated hydraulic pressure and mechanical force coupling electric power-assisted braking system

A technology of electric power assist and braking system, which is applied in the direction of braking safety system, brake, braking transmission device, etc., to achieve the effect of fast response speed, simple structure and simplified control algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

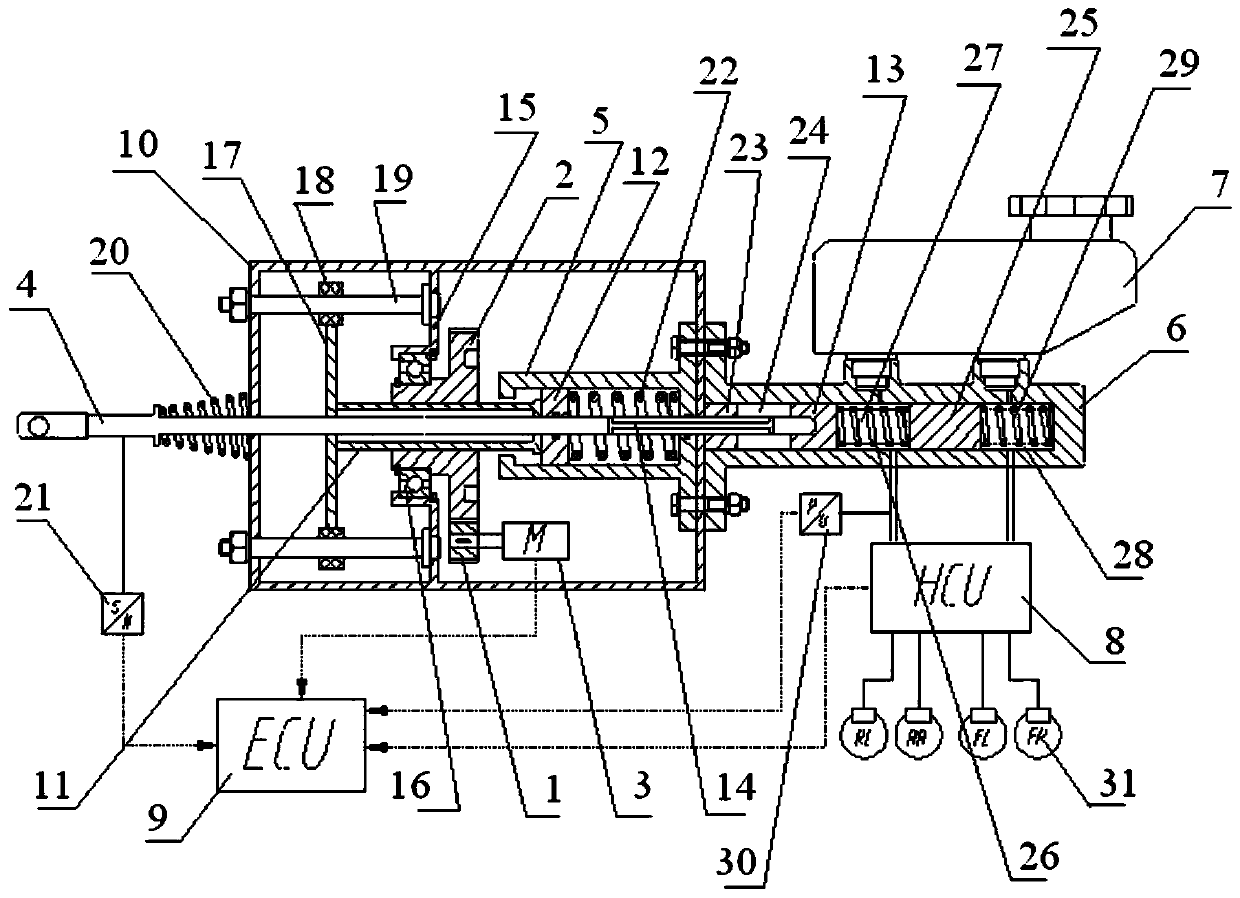

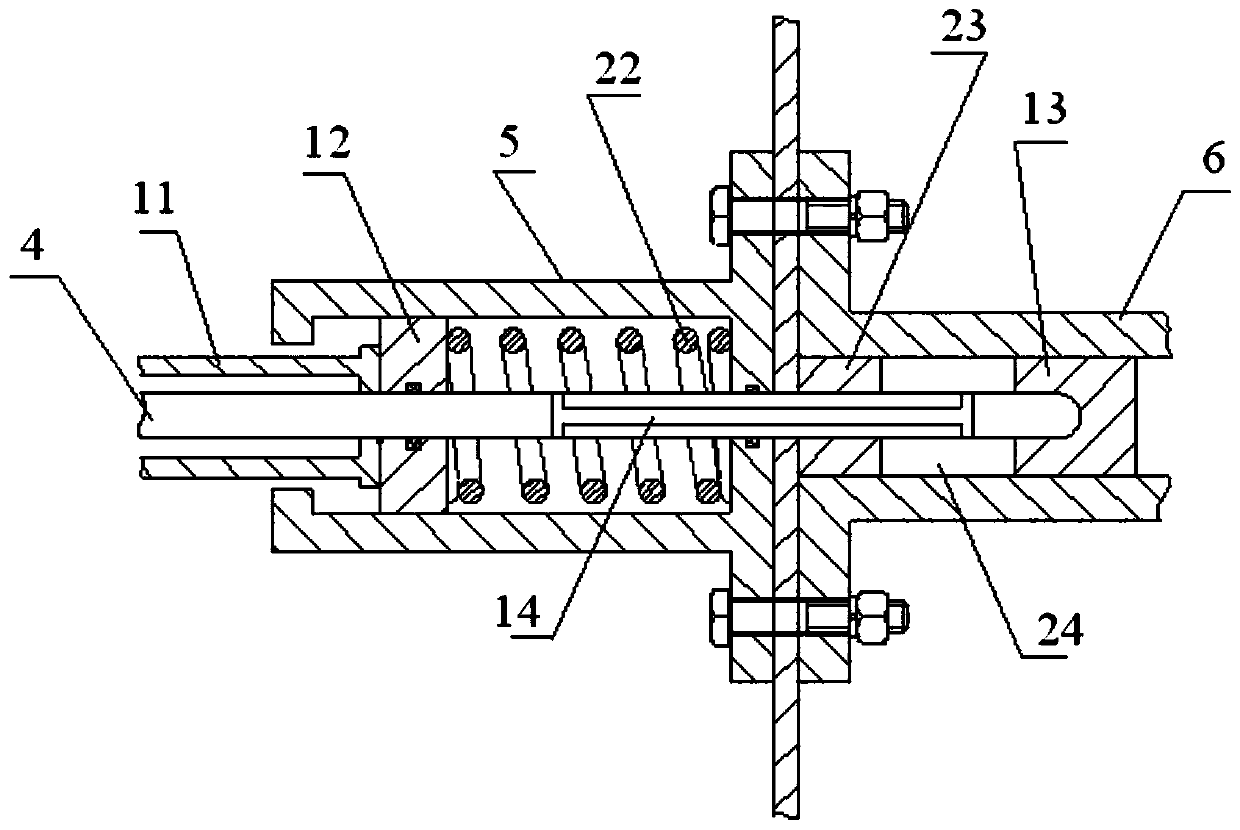

[0038] see Figure 1 to Figure 2 Shown:

[0039] The electric power-assisted braking system with integrated hydraulic pressure and mechanical force coupling provided by the present invention includes a first gear 1, a second gear 2, a power-assisted motor 3, a pedal push rod 4, a power-assisted pressure building cylinder 5, and a brake master cylinder 6 , a liquid storage tank 7, a hydraulic control unit 8 and an electric control unit 9, wherein the first gear 1, the second gear 2, the booster motor 3 and the booster pressure building cylinder 5 are assembled in a housing 10, the booster motor 3 and the first The gear 1 is connected and drives the first gear 1 to rotate. The first gear 1 meshes with the second gear 2 to drive the second gear 2 to rotate synchronously. The second gear 2 is screwed with a screw 11 in the middle, and the screw 11 is a hollow structure , during the rotation of the second gear 2, the screw rod 11 is driven to move left and right, the rear end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com