PTFE resin composite material of sealing ring with high thermal conductivity used for rotating shaft and preparation method thereof

A resin composite material and high thermal conductivity technology, applied in the field of composite materials, can solve the problems of small friction coefficient, thermal stability, poor dimensional stability, and low dielectric strength, etc., and achieve increased thermal conductivity, reduced thermal expansion coefficient, and increased thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

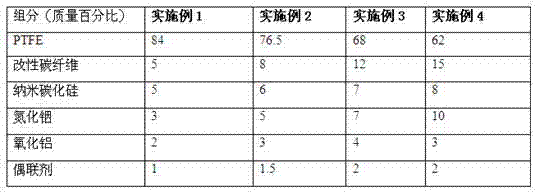

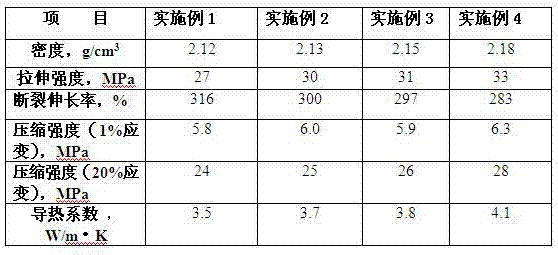

Embodiment 1-4

[0023] The preparation method of the sealing ring for the high thermal conductivity rotating shaft of the scroll compressor of the air conditioner comprises the following steps:

[0024] (1) Carbon fibers are soaked in acetone, washed, dried, added to acid solution at 60-70°C and stirred for 0.5-2 hours, filtered, washed until neutral, and acidified carbon fibers are obtained;

[0025] (2) Weigh the raw materials according to the amount, add them to the high-speed mixer, stir at high speed for 2-3 minutes, take them out, and place them for 2-6 hours;

[0026] (3) Use a press for cold pressing, with a pressure of 10~30MPa, a holding time of 1min, and demoulding to obtain a preformed sample;

[0027] (4) Put the preformed sample into the sintering furnace, sinter at 400±5°C for 3~6h, cool down to room temperature naturally with the furnace, and machine to obtain the wear-resistant and dust-proof sealing strip for the air scroll compressor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com