Overhanging type outer scaffold and construction method

An external scaffolding and construction method technology, which is applied to the accessories of the scaffolding, the scaffolding supported by the house structure, the support of the house structure, etc., can solve the problem of residual construction holes, large demand for I-beam materials, and difficulty in controlling the parallelism of pre-embedded connecting wall rods. and other problems, to achieve the effect of saving construction costs, improving construction efficiency, and avoiding uncontrollable parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

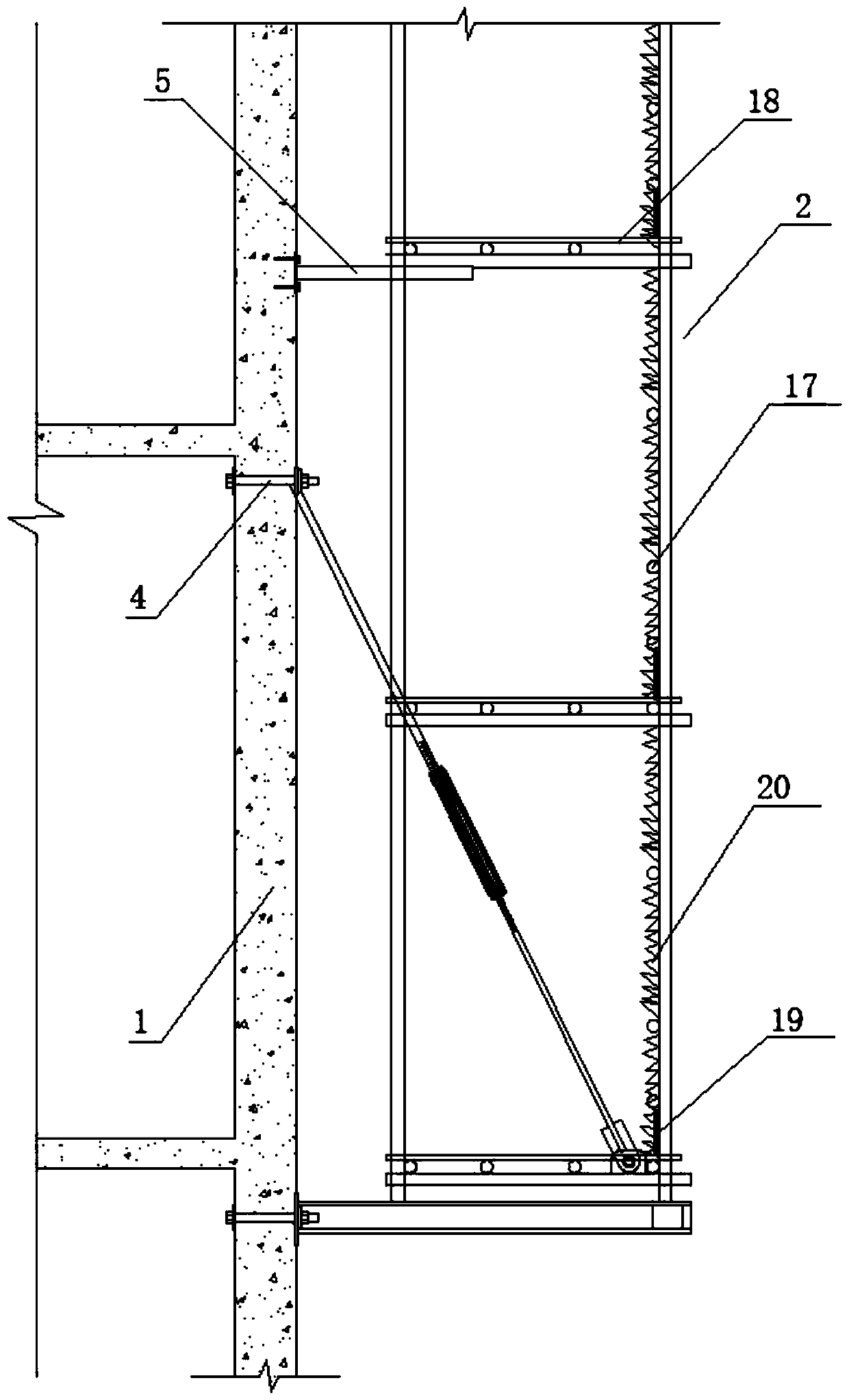

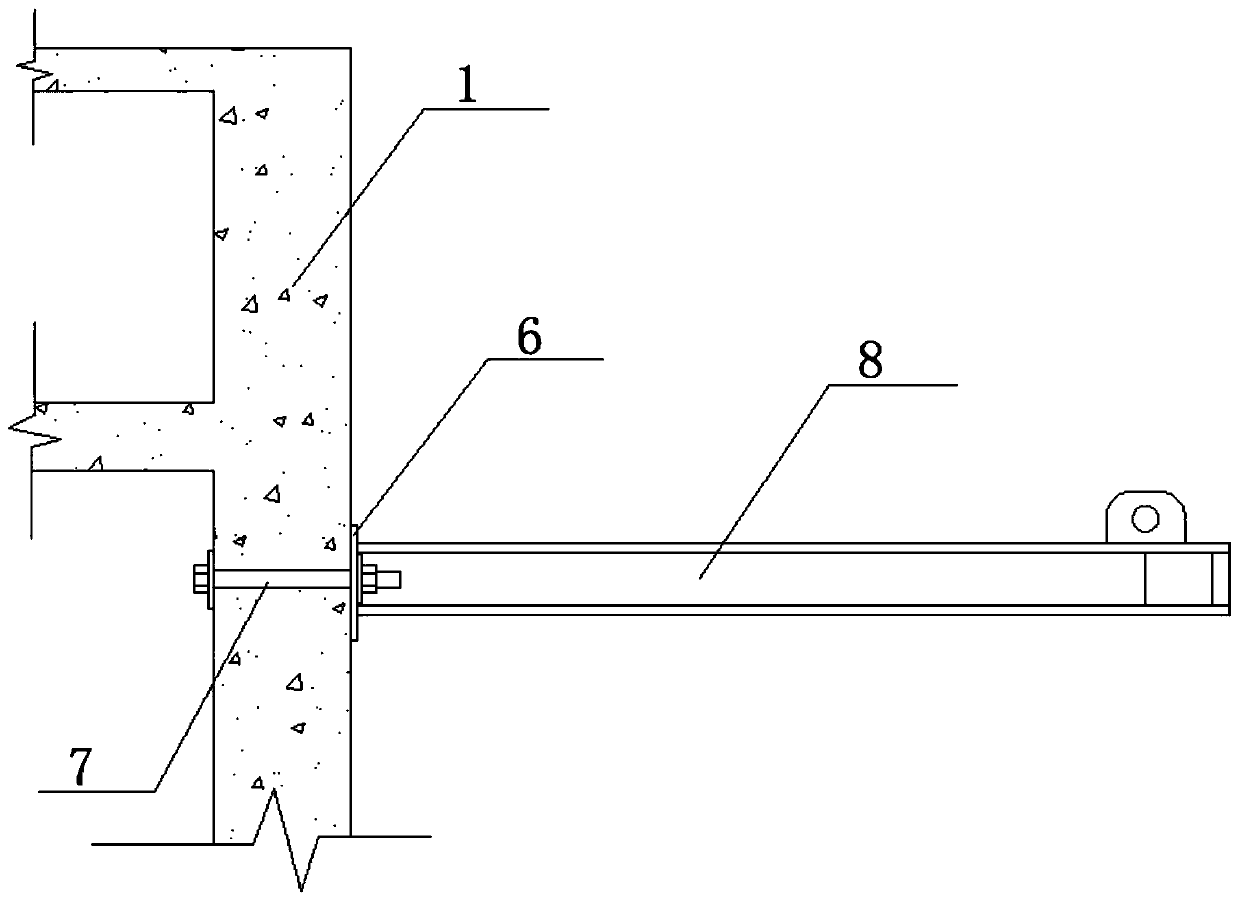

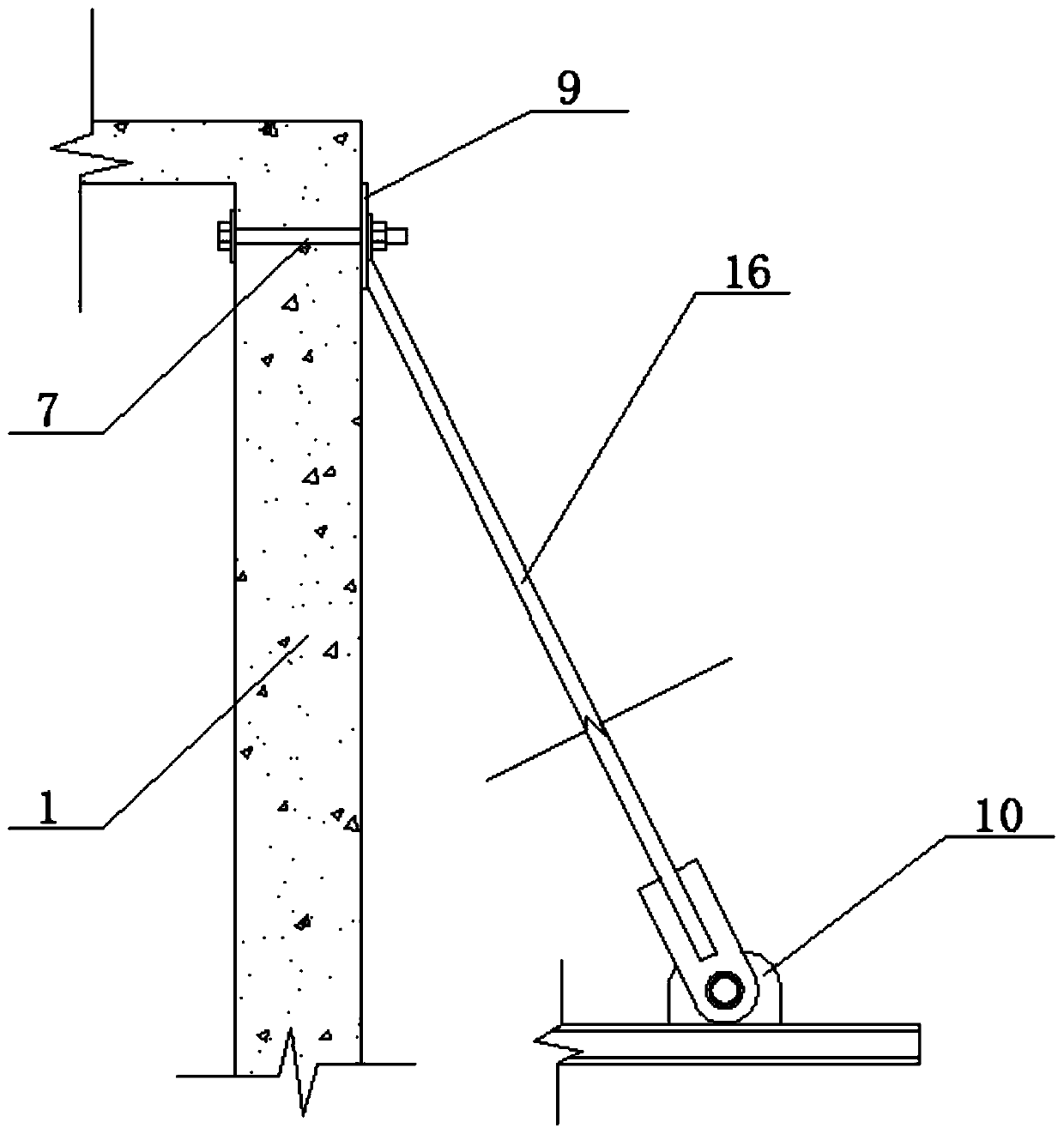

[0040] According to the manual attached Figures 1 to 4 Shown is a cantilevered external scaffold and its construction method,

[0041] The first connecting steel plate 6 is made of 12-thick galvanized flat steel, and two bolts are reserved for fixing with No. 16 I-beam, and then tightened with double nuts, and the tightening torque is 40-65 N·m.

[0042]The second connecting steel plate 9 is made of 12-thick galvanized flat steel, and a bolt is reserved for fixing with one end of the Ф20 tie rod 11, and then tightened with double nuts, the tightening torque is 40-65 N·m. The other end of the Ф20 pull rod 11 is fixed with a pin bolt to the third connecting steel plate 10 on the upper end of No. 16 I-beam, and the third connecting steel plate 10 also adopts 12 thick galvanized flat steels and is fully welded with No. 16 I-beam.

[0043] The fourth connecting steel plate 12 is made of galvanized flat steel with a size of 200×100×10. One end of the connecting wall rod 13 is full...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com