High-thermal-conductivity PTFE (polytetrafluoroethylene) resin composite for sealing strip in high-temperature region and preparation method of PTFE resin composite

A resin composite material and sealing strip technology, applied in the field of composite materials, can solve the problems of small friction coefficient, thermal stability, poor dimensional stability, low dielectric strength, etc., and achieve high electrical conductivity, reduce thermal expansion coefficient, and improve thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

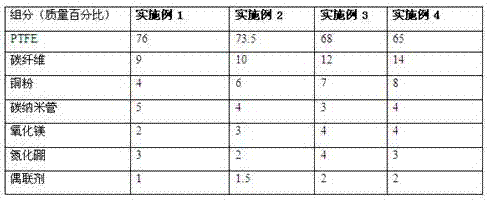

[0026] The preparation method of the high heat conduction high temperature zone sealing strip for the air scroll compressor comprises the following steps:

[0027] (1) Carbon nanotubes and carbon fibers are respectively soaked in acetone, washed, dried, put into concentrated sulfuric acid or concentrated nitric acid and stirred at 60-70°C for 0.5-2h, suction filtered, washed until neutral, and acidified carbon nanotubes and acidified carbon fibers;

[0028] (2) Add copper powder, magnesium oxide and boron nitride to the coupling agent, stir and mix;

[0029] (3) Add the product obtained in step (1) (2) and polytetrafluoroethylene powder into an organic solvent and stir until they are evenly mixed. The contents of each component are shown in Table 1;

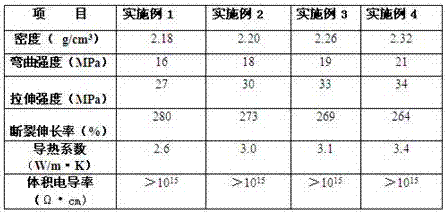

[0030] (4) The mixed solution obtained in step (3) is injected into the mold of the sealing strip, and after cold pressing, it is sintered at a high temperature at a temperature of 370-400° C. to obtain a high thermal conductivi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com