Low-NOx mixed burning system and method with coupling of pyrolyzing furnace and pulverized coal boiler

The technology of pulverized coal boiler and pyrolysis furnace is applied in the field of low NOx mixed combustion system coupled with pyrolysis furnace and pulverized coal boiler, which can solve the problems of low calorific value of pyrolysis gas, waste of resources and environment, and difficulty in direct utilization, etc. To achieve the effect of reducing environmental pollution, saving costs and improving combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with accompanying drawing

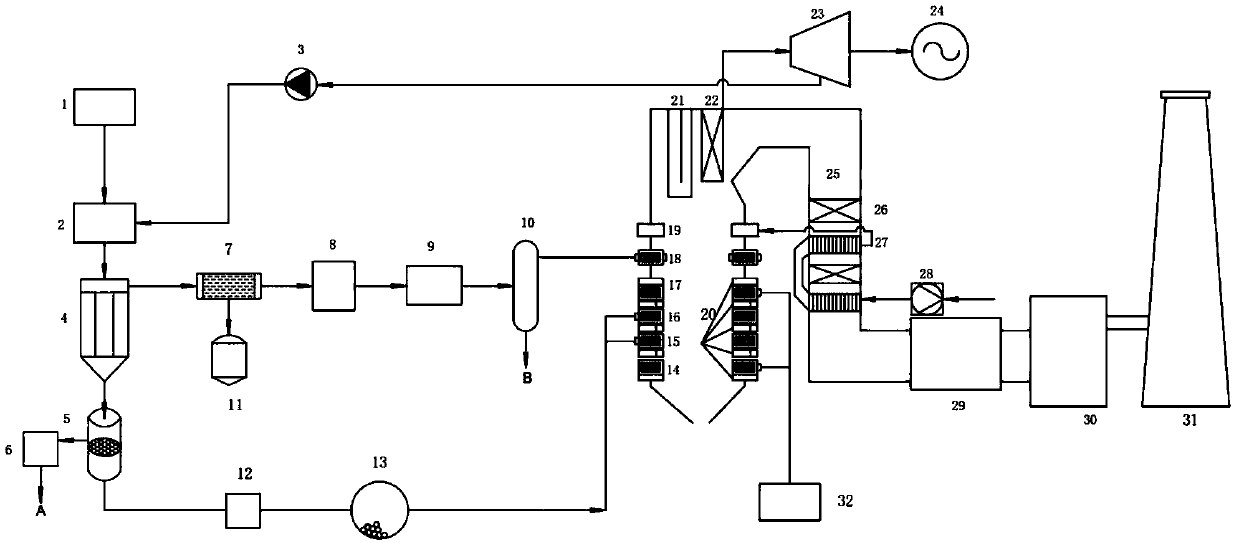

[0034] Such as figure 1 As shown, the present invention provides a pyrolysis furnace-coal pulverized boiler coupled low NO x Co-combustion system, including coal pyrolysis system and pyrolysis semi-coke and bituminous coal co-combustion system.

[0035] The coal pyrolysis system includes a raw coal bunker 1, a dryer 2, a steam pump 3, a pyrolysis furnace 4, a semi-coke collection device 5, a semi-coke large hopper 6, a condenser 7, a pyrolysis gas dedusting device 8, a thermal Degassing and desulfurization device 9, pyrolysis gas collecting device 10, tar trapping device 11, steam turbine 23 and steam delivery pipeline.

[0036] The blending system of pyrolysis semi-coke and bituminous coal adopts the method of "separate grinding and pulverization, layered blending in the furnace" combined with "fuel reburning". The blending system includes a semi-coke small hop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com