High-speed self-balancing spindle oil dividing structure of inertia friction welding machine

A friction welding machine, self-balancing technology, applied in mechanical equipment, welding equipment, bearing components, etc., can solve problems such as poor sealing life of the joint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings. The embodiments are exemplary and are only used to disclose and explain the present invention so as to fully understand the present invention, but the present invention is not therefore limited within the scope of the described embodiments. .

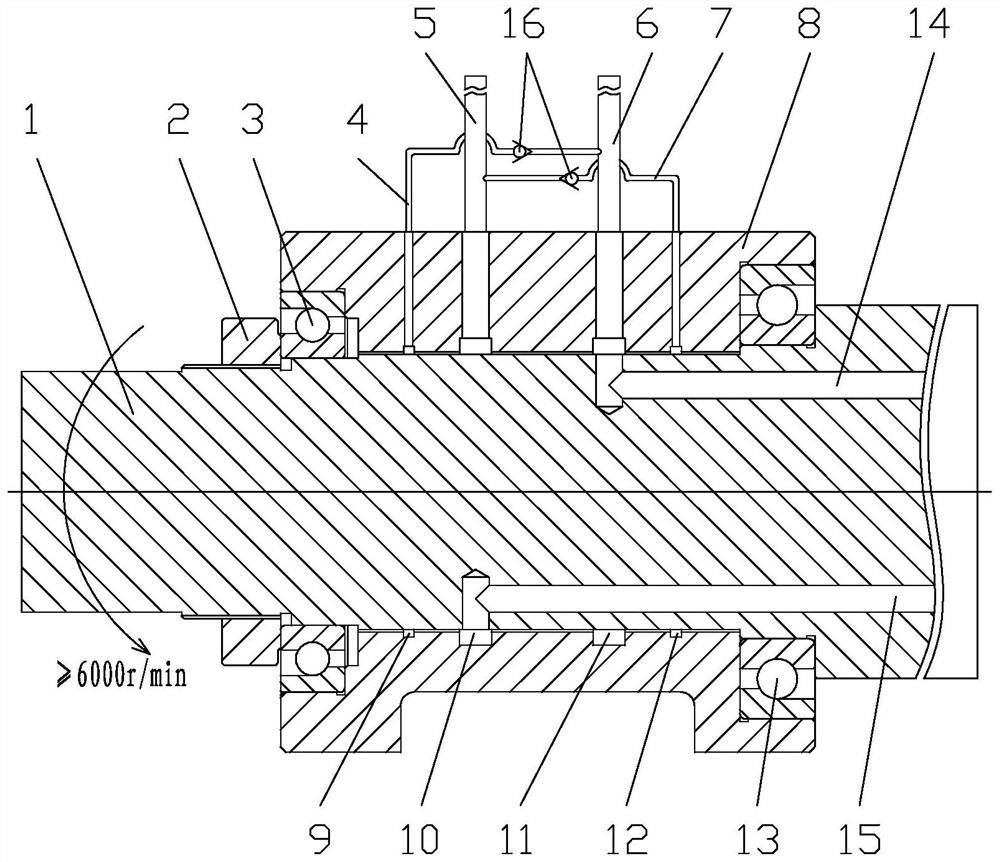

[0016] See attached figure 1 , a high-speed self-balancing main shaft oil separation structure of an inertial friction welding machine, including a main shaft 1 and an oil distribution member, the rotation speed of the main shaft 1 is ≥ 6000r / min, an oil inlet passage 15 and an oil return passage 14 are arranged on the main shaft 1, and the oil distribution member is on An oil inlet port 5 and an oil return port 6 are provided, and the oil inlet port 5 and the oil return port 6 are connected to the external hydraulic system through a hose; The rolling bearings at both ends are rotatably arranged on the main shaft 1, and a dynamic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com