Drilling liner cementing tool with packer and cementing method

A liner cementing and packer technology, which is applied in the field of oil and gas well drilling and completion, can solve the problems of easy encountering resistance, limitation of open pump circulation pressure, and the inability of packer to play annulus isolation, so as to reduce the The risk of leakage, improving the success rate of running, improving the success rate of running and the effect of cementing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

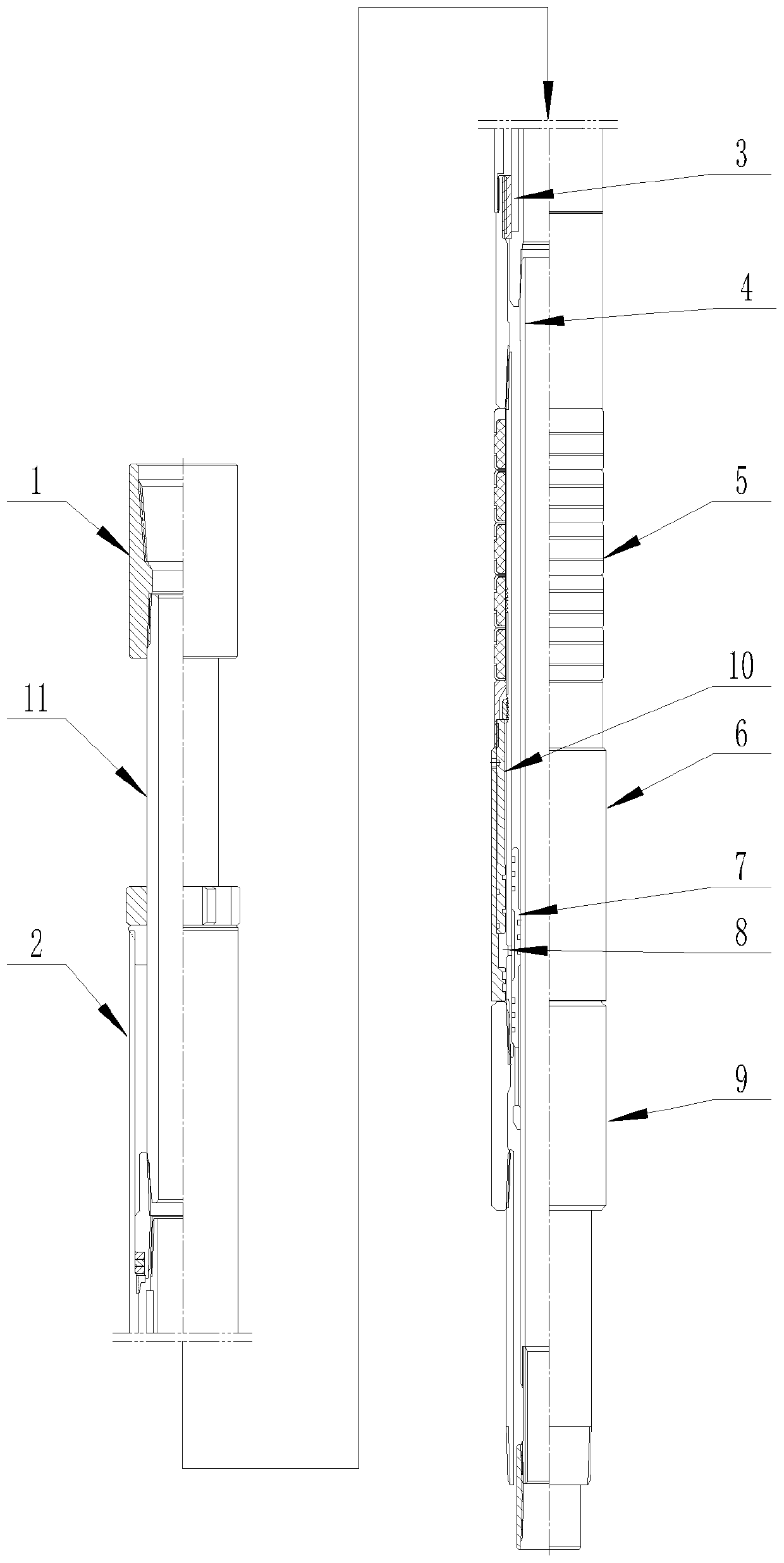

[0033] refer to figure 1 , is a structural schematic diagram of Embodiment 1 of the present invention, a liner cementing tool with a packer, including

[0034] Tool body 10;

[0035] The central core pipe 4, the central core pipe 4 is socketed in the tool body 10;

[0037] Lifting sub 11, one end of the lifting sub 11 is connected with the drill pipe joint 1, and the other end of the lifting sub 11 is connected with the core pipe 4;

[0038] The reverse screw sleeve 3, the reverse screw sleeve 3 is connected to the outer wall of the lifting nipple 11 connected with the core tube 4, and the core tube 4 is socketed in the tool body 10 through the reverse screw sleeve 3;

[0039] Tie-back barrel 2, the tie-back barrel 2 is connected to the outer wall of the top of the tool body 10;

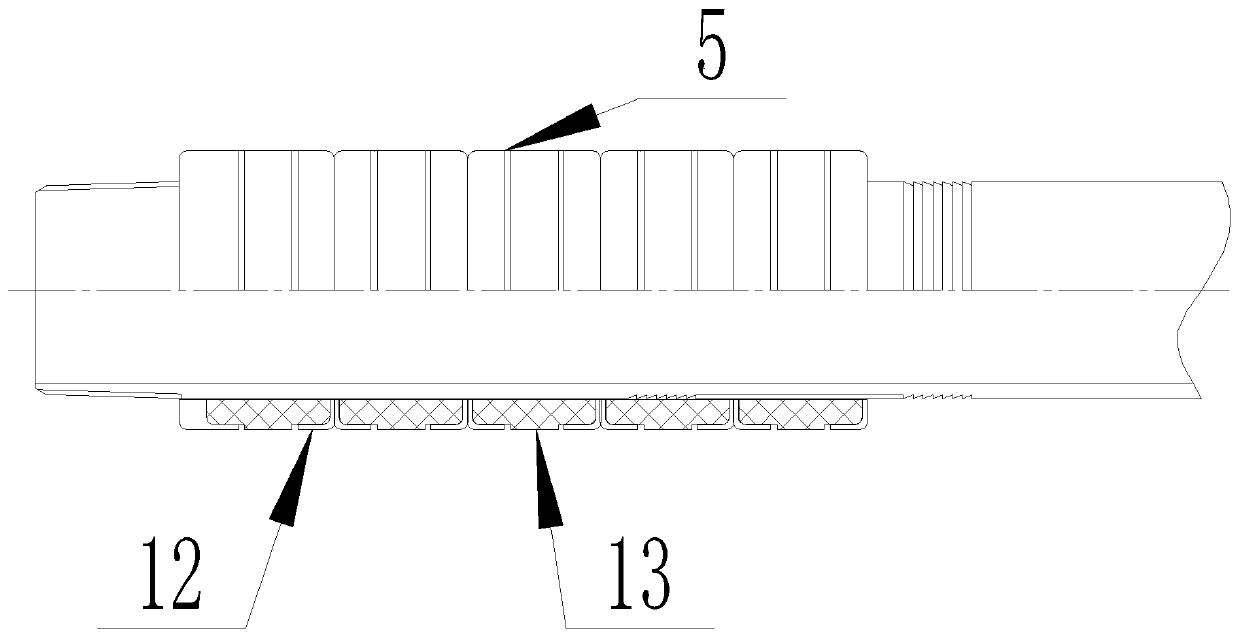

[0040] A packer 5, the packer 5 is connected to the outer wall of the tool body 10 at the lower end of the tie-back barrel 2;

[0041] A hydraulic cylinder 6, the hy...

Embodiment 2

[0045] Compared with Embodiment 1, the difference of this embodiment is that: the outer wall of the core tube 4 where the tool body 10 and the core tube 4 are socketed is connected with a sealing sleeve 7 .

[0046] During actual use: the sealing sleeve 7 acts as a movable seal after losing hands, so as to ensure the successful implementation of the cementing operation.

Embodiment 3

[0048] Compared with Embodiment 1, the difference of this embodiment is that: there is a liquid inlet hole 8 between the inner wall of the tool body 10 and the inner cavity of the hydraulic cylinder 6 .

[0049] In actual use: the liquid inlet hole 8 is set between the inner wall of the tool body 10 and the inner cavity of the liquid cylinder 6, so as to ensure that the liquid enters the liquid cylinder 6 when the central tube 4 is lifted up, and avoids when the central tube 4 is not lifted up. Liquid just enters liquid cylinder 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com