Method and system for carrying out atomization deodorization by adopting plant extract solution

A plant extraction liquid and liquid technology, which is applied in chemical instruments and methods, separation methods, and dispersed particle separation, etc., can solve the problems of long-distance transmission of gas-liquid two-phase flow in pipelines, reduction of operation risks, and difficulty in transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

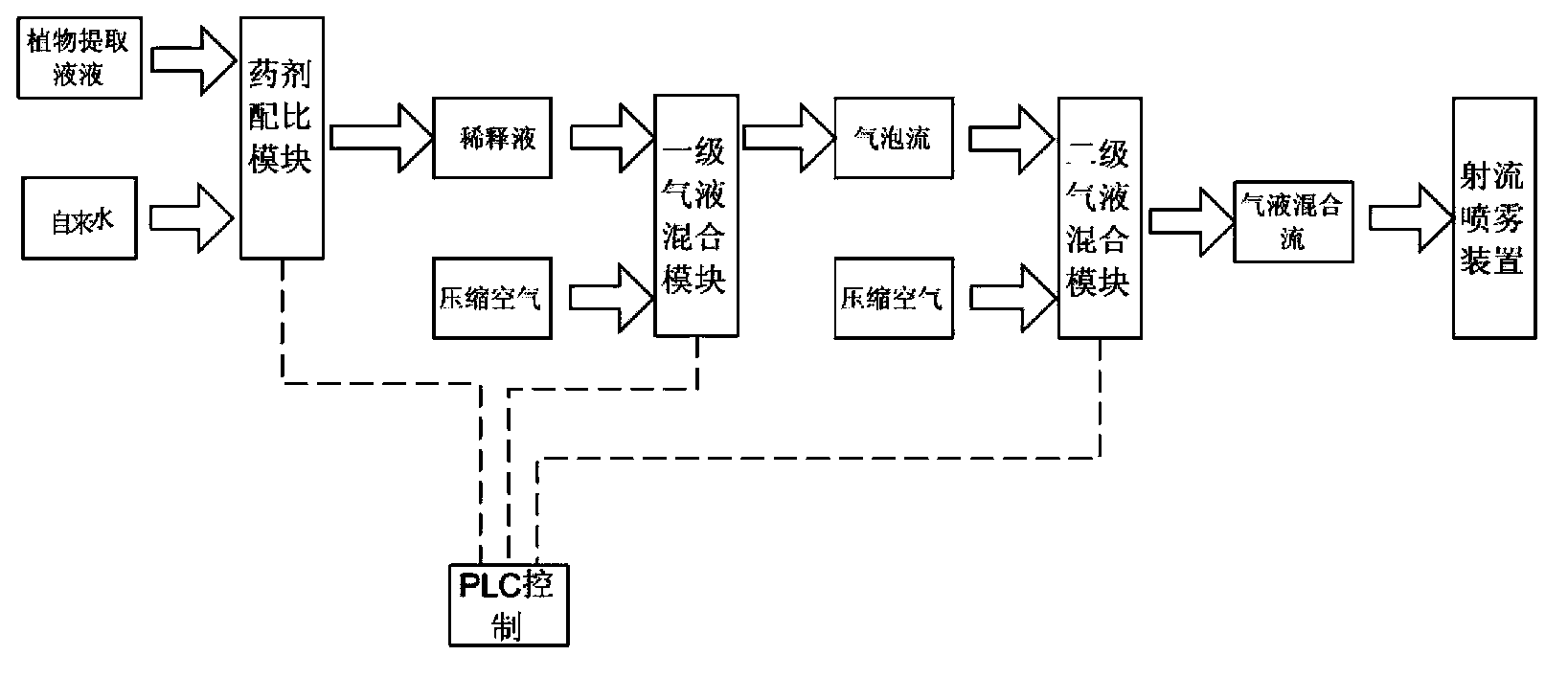

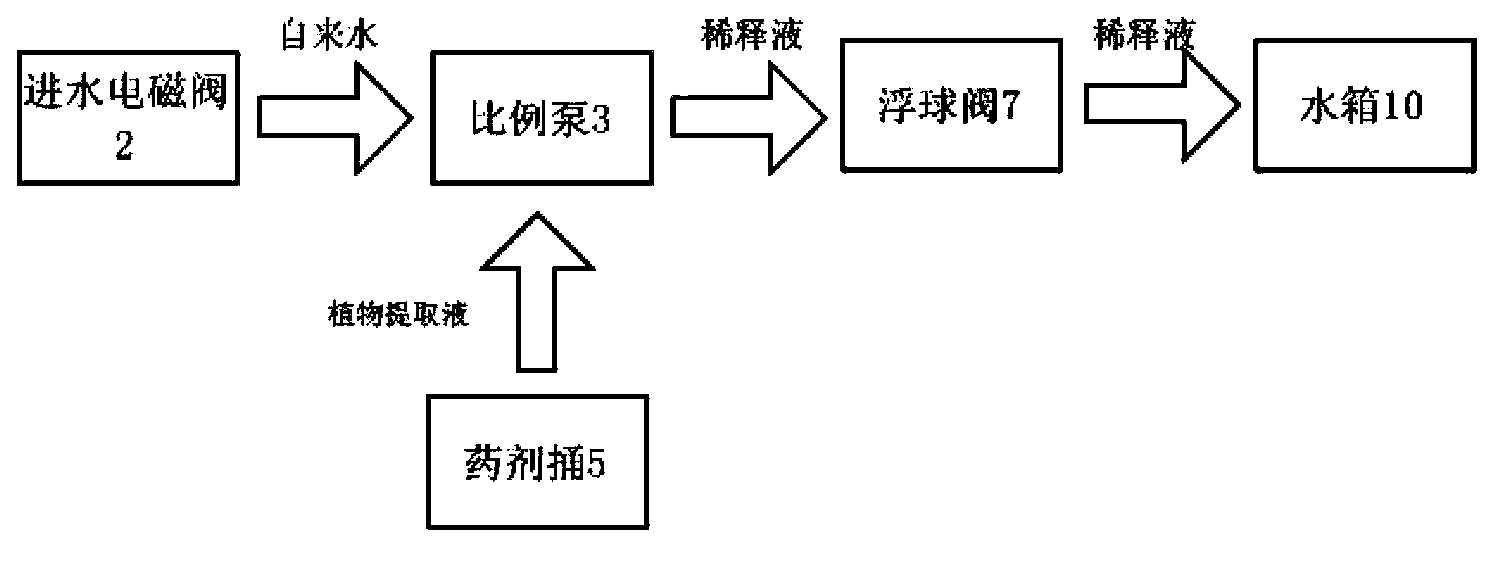

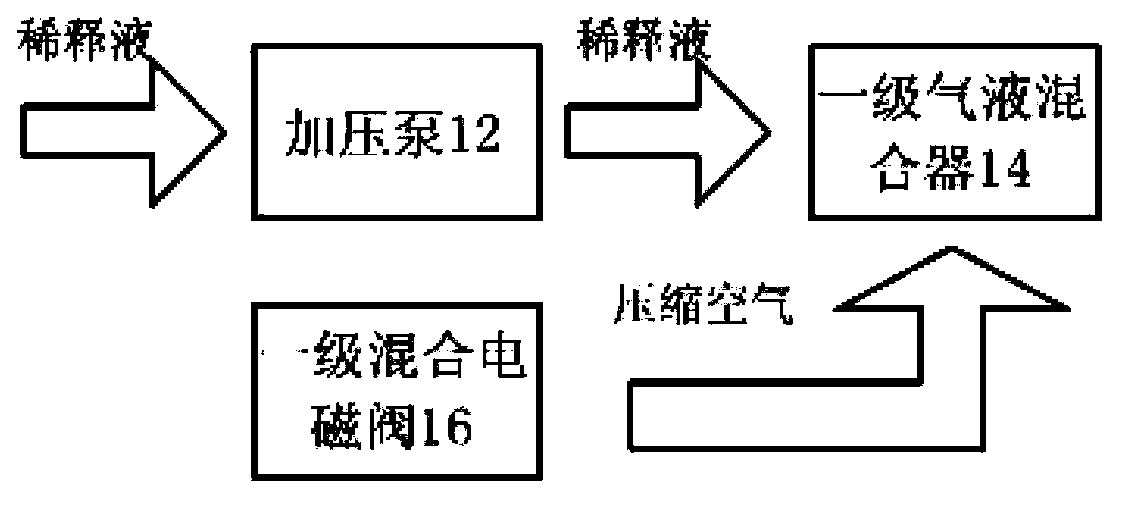

[0042] According to the actual situation on site, the flocs produced in the plant extract hindered the occurrence of high-pressure atomization and caused a series of equipment failures. In the case where the medium cannot be changed, if the plant extract can be atomized under low pressure, the requirements for the cleanliness of the medium in the entire system will be reduced, and failures can also be avoided.

[0043] In the comparison of existing technologies, it is found that pressure atomization is sprayed into a relatively slow gas environment at a relatively high liquid rate, and its pipeline transportability is good, but the medium pressure is high and requires high equipment precision. The gas-liquid two-fluid atomization is to enter the relatively high-velocity airflow at a lower liquid velocity or the disturbance of a relatively high-velocity airflow to a lower-velocity liquid. The medium pressure is low and the adaptability to the liquid is strong. However, the atom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com